Organic silicon modified unsaturated higher aliphatic alcohol ester defoamer and preparation method thereof

A technology of alcohol ester defoamer and higher fatty alcohol, which is applied in chemical instruments and methods, separation methods, foam dispersion/prevention, etc. Restricting the scope of application and other issues, to achieve the effect of improving the water filtration performance of the paper machine, strong foam suppression ability, and prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

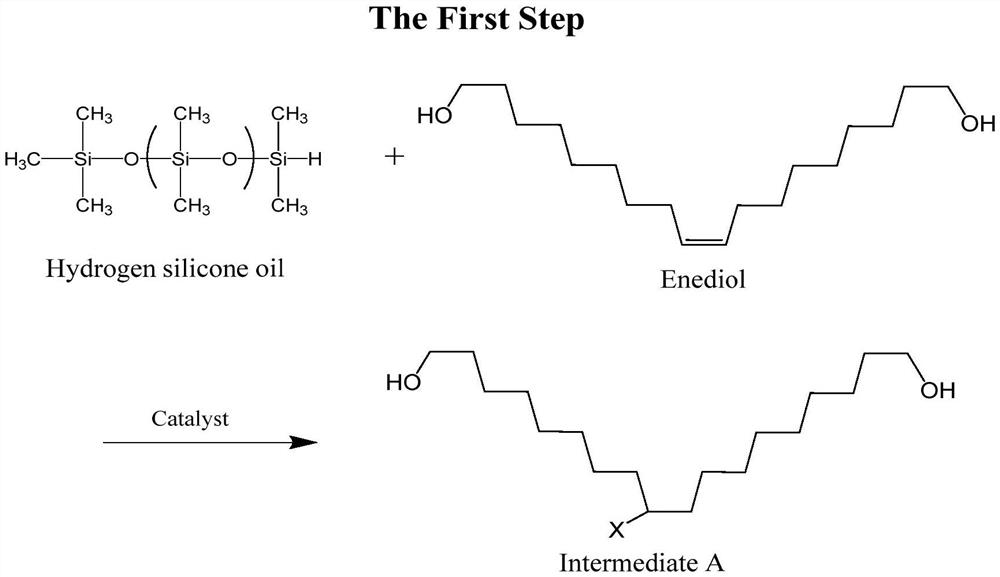

[0041]1) Put octadecylenediol with a molar ratio of 1:0.8 and hydrogen-containing silicone oil with a hydrogen content of 0.05% in the reactor, start stirring and raise the temperature, set the pressure at -0.07MPa, and the temperature at 70°C. The time is 50min, carry out water removal, remove low-boiling impurity treatment, then turn off vacuum, add the 0.1% chloroplatinic acid catalyst of system material gross mass, in N 2 Under a protected environment, the temperature was raised to 95° C. and kept for 4 hours to terminate the reaction to obtain an intermediate.

[0042] 2) Put the intermediate and lauric acid with a molar ratio of 1:2.2 in another reactor and start stirring, start to heat up to 75°C, add 0.5% p-toluenesulfonic acid, turn on the vacuum to -0.08MPa, and start to heat up , the temperature was raised to 130° C. for 8 hours, then the vacuum was turned off, the temperature was lowered and the material was discharged to obtain the product.

[0043] 3) Take 10g o...

Embodiment 2

[0046] 1) Put dodecenol with a molar ratio of 1:1 and hydrogen-containing silicone oil with a hydrogen content of 0.1% in the reaction kettle, start stirring and heat up, set the pressure at -0.08MPa, the temperature at 80°C, and the time Be 30min, carry out dewatering, remove low-boiling impurity treatment, then turn off vacuum, add the 0.2% chloroplatinic acid catalyst of system material gross mass, in N 2 Under a protected environment, the temperature was raised to 105° C. and kept for 3 hours to terminate the reaction to obtain an intermediate.

[0047] 2) Put the intermediate and stearic acid with a molar ratio of 1:1.5 in another reactor and start stirring, start to heat up to 80°C, add 0.3% sulfamic acid, turn on the vacuum to -0.085MPa, and start to heat up , the temperature was raised to 140° C. for 6 hours, then the vacuum was turned off, the temperature was lowered and the material was discharged to obtain the product.

[0048] 3) Take 15g of silicone-modified unsa...

Embodiment 3

[0051] 1) Put octadecenol with a molar ratio of 1:2.5 and hydrogen-containing silicone oil with a hydrogen content of 0.15% in the reactor, start stirring and heat up, set the pressure at -0.09MPa and the temperature at 90 ℃, the time is 20min, carry out dehydration, remove the treatment of low-boiling point impurities, then turn off the vacuum, add 0.5% chloroplatinic acid catalyst of the total mass of the system material, in N 2 Under a protected environment, the temperature was raised to 125° C. and kept for 0.5 h to complete the reaction to obtain an intermediate.

[0052] 2) Put the intermediate and behenic acid with a molar ratio of 1:0.85 in another reactor and start stirring, start to heat up to 95°C, add 0.1% methanesulfonic acid, turn on the vacuum to -0.09MPa, and start to heat up , the temperature was raised to 165° C. for 2 hours, then the vacuum was turned off, the temperature was lowered and the material was discharged to obtain the product.

[0053] 3) Take 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com