Defoaming agent suitable for polymer cement waterproof mortar and preparation method thereof

A technology for waterproof mortar and defoaming agent, applied in the field of defoaming agent suitable for polymer cement waterproof mortar and its preparation, can solve problems such as poor compatibility and mortar defects, achieve stable performance, good spreading performance, and improve mechanical properties. The effect of performance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

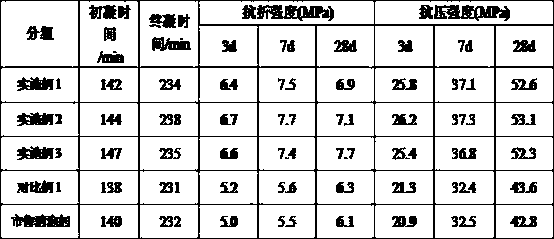

Examples

Embodiment 1

[0021] A method for preparing a defoamer suitable for polymer cement waterproof mortar, characterized in that the raw materials are composed of: 80 parts of tetrahydrofuran, 20 parts of ethylenediamine, 12 parts of ethyl orthosilicate, 3 parts of fluorosilane, 8 parts of methyl siloxane, 0.6 parts of emulsifier, 1 part of nonylphenol polyoxyethylene ether, 20 parts of acrylic monomer, 0.1 part of initiator, 2 parts of white carbon black, nano-SiO 2 Airgel 1 part, preservative 0.02 part and deionized water 44 parts.

[0022] As mentioned, the fluorosilane is nonafluoroethyltrimethyloxysilane.

[0023] Said polydimethylsiloxane has a viscosity of 300-400mPa·s.

[0024] As mentioned, nano-SiO 2 The specific surface area of airgel powder is 985.6m 2 / g, the purity is 99%.

[0025] Described, emulsifier is sodium dodecylbenzenesulfonate.

[0026] Described, initiator is potassium persulfate.

[0027] A kind of preparation method that is applicable to the defoamer of polymer...

Embodiment 2

[0034] A method for preparing a defoamer suitable for polymer cement waterproof mortar, characterized in that the raw materials are composed of: 100 parts of tetrahydrofuran, 35 parts of ethylenediamine, 18 parts of ethyl orthosilicate, 5 parts of fluorosilane, 12 parts of methyl siloxane, 4.5 parts of emulsifier, 2 parts of nonylphenol polyoxyethylene ether, 35 parts of acrylic monomer, 1 part of initiator, 5 parts of white carbon black, nano-SiO 2 3 parts of airgel, 0.1 part of preservative and 73 parts of deionized water.

[0035] As mentioned, the fluorosilane is heptadecafluorosilane.

[0036] Said polydimethylsiloxane has a viscosity of 300-400mPa·s.

[0037] As mentioned, nano-SiO 2 The specific surface area of airgel powder is 985.6.8m 2 / g, the purity is 99%.

[0038] Described, emulsifier is sodium dodecylbenzenesulfonate.

[0039] Described, initiator is potassium persulfate.

[0040] A kind of preparation method that is applicable to the defoamer of polymer...

Embodiment 3

[0047] A method for preparing a defoamer suitable for polymer cement waterproof mortar, characterized in that the raw materials are composed of: 120 parts of tetrahydrofuran, 45 parts of ethylenediamine, 24 parts of tetraethyl orthosilicate, 8 parts of fluorosilane, 15 parts of methyl siloxane, 9 parts of emulsifier, 3 parts of nonylphenol polyoxyethylene ether, 55 parts of acrylic monomer, 2 parts of initiator, 8 parts of white carbon black, nano-SiO 2 Airgel 5 parts, preservative 3 parts and deionized water 103 parts.

[0048] As mentioned, the fluorosilane is trifluoromethyltrimethylsilane.

[0049] Said polydimethylsiloxane has a viscosity of 300-400mPa·s.

[0050] As mentioned, nano-SiO 2 The specific surface area of airgel powder is 345.8m 2 / g, the purity is 99%.

[0051] Described, emulsifier is sodium dodecylbenzenesulfonate.

[0052] Described, initiator is potassium persulfate.

[0053] A kind of preparation method that is applicable to the defoamer of polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com