Latex cement defoaming agent and preparation method thereof

A defoamer and cement technology, applied in the field of oil well cementing, can solve the problems of few types of defoamer, poor defoaming effect, inability to meet drilling technology and other problems, and achieves no secondary pollution, strong and good foam suppression ability. Effects on storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

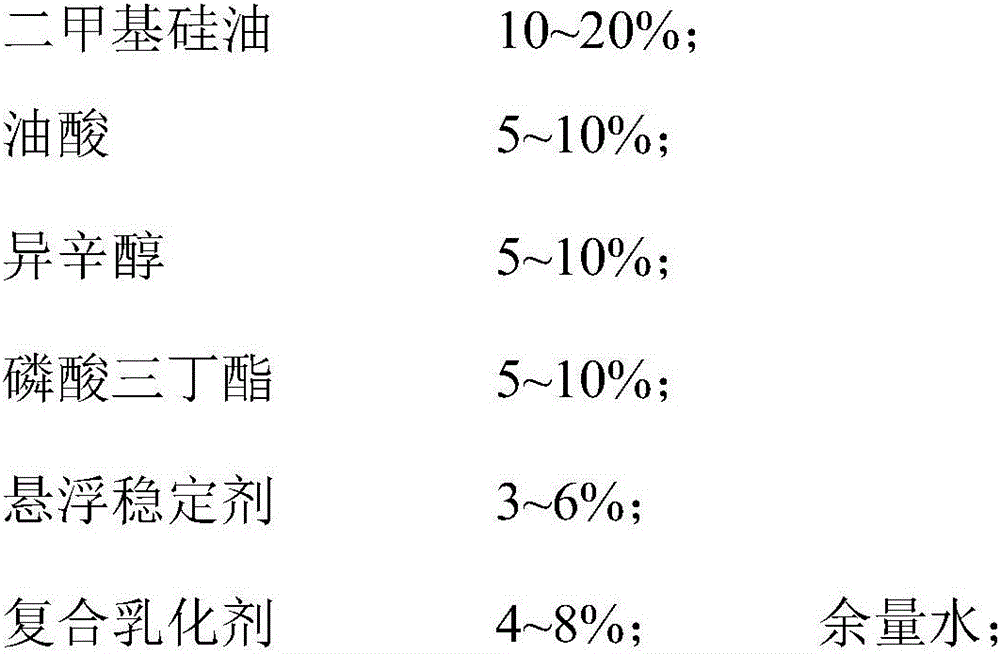

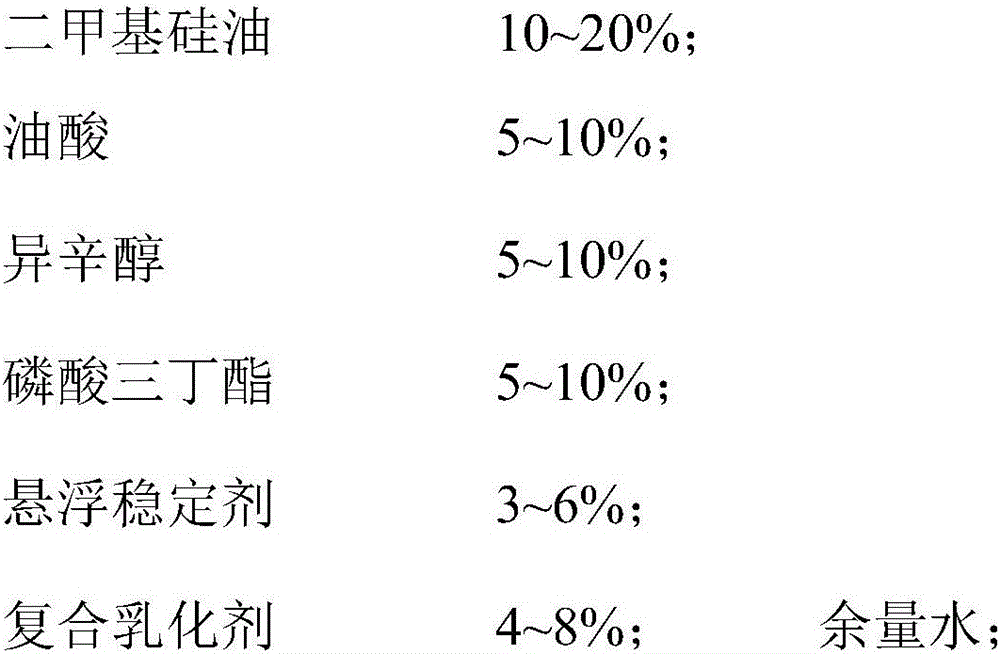

Method used

Image

Examples

Embodiment 1

[0023] According to mass percent, 15% simethicone, 5% oleic acid, 5% isooctyl alcohol, 8% tributyl phosphate, 4% Tween-60 and AEO (both volume ratios are 1: 1) Add the mixture and the remaining amount of water into a round-bottomed flask, stir, and raise the temperature to 80°C. After stirring for 1.5 hours, a white milky mixture is formed. Then add 4% microsilicon, continue stirring for 0.5 hours, and the product is obtained after cooling.

Embodiment 2

[0025] According to mass percent, 15% simethicone, 8% oleic acid, 8% isooctyl alcohol, 6% tributyl phosphate, 5% Tween-60 and AEO (both volume ratios are 1: 1) Add the mixture and the remaining amount of water into a round-bottomed flask and stir, and heat up to 80°C. After stirring for 1.5 hours, a white milky mixture is formed, and then add 3% carboxymethyl cellulose, continue stirring for 0.5 hours, and obtain after cooling product.

Embodiment 3

[0027] According to mass percent, 12% simethicone, 8% oleic acid, 10% isooctyl alcohol, 6% tributyl phosphate, 5% Tween-60 and AEO (both volume ratios are 1: 0.8) Add the mixture and water into a round bottom flask and stir, and heat up to 80°C. After stirring for 1.5 hours, a white milky mixture is formed. Then add 3% carboxymethyl cellulose, continue stirring for 0.5 hours, and obtain the product after cooling.

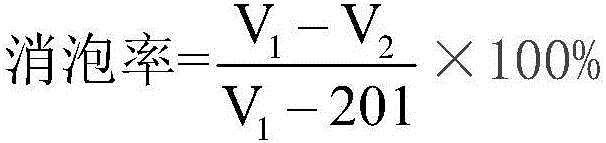

[0028] Defoamer effect evaluation:

[0029] Weigh 0.8g of analytically pure octylphenol polyoxyethylene ether, put it into 200ml of distilled water, and make a solution. Pour the prepared solution into the slurry cup of a constant speed stirrer, stir at 4000r / min±200r / min for 50s, then pour it into a 1000ml measuring cylinder within 5s, record the volume V of the solution 1 (ml) (including foam).

[0030] Weigh 0.8 g of analytically pure octylphenol polyoxyethylene ether, weigh the product in the above examples, put it into 200 ml of distilled water at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com