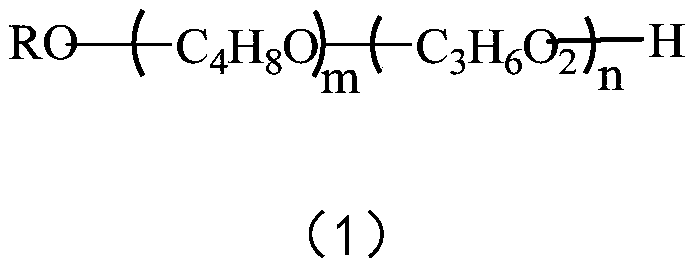

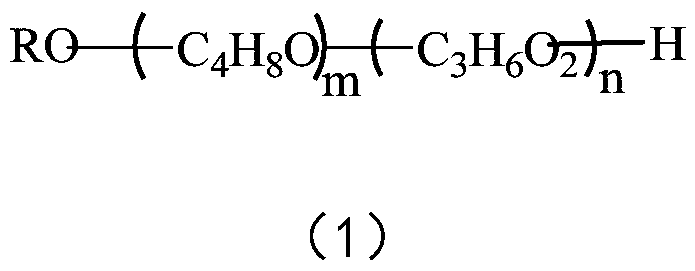

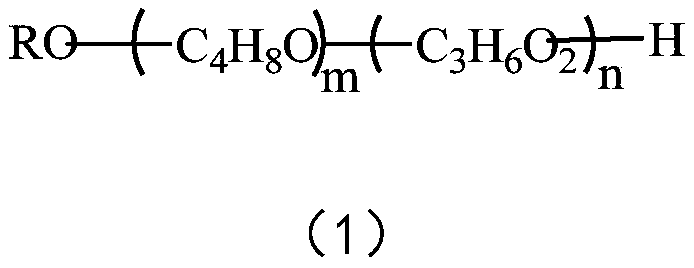

Fatty alcohol polyoxybutylene ether polyglycerol ether and preparation method and application thereof

A technology of alcohol polyoxybutene ether and polyoxybutene ether, which is applied in the field of fatty alcohol polyoxybutene ether, polyglycerol ether and its preparation, and can solve the problem that detergents cannot satisfy high foaming and fast defoaming performance at the same time. problems, to achieve the effect of reducing the number of washing and rinsing, saving water resources, and reducing the amount of addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] This embodiment relates to a kind of fatty alcohol polyoxybutylene ether polyglyceryl ether, which is prepared according to the following steps:

[0076] S1. Preparation of fatty alcohol polyoxybutylene ether: Weigh 130.23g (1mol) of isooctyl alcohol and 11.6g of potassium hydroxide into the reaction kettle, turn on the vacuum, dehydrate for 0.5 hours, pass in nitrogen, add 216.33g (3mol) of ring Oxybutane, react at a temperature of 125°C until the pressure is constant, cool down to 90°C after aging for 1 hour, and obtain fatty alcohol polyoxybutylene ether;

[0077] S2. Preparation of fatty alcohol polyoxybutylene ether polyglyceryl ether: Add 814.88 g (11 mol) of glycidol dropwise to fatty alcohol polyoxybutylene ether at a temperature of 100° C. for 2 hours, and continue after the addition Keep warm for 2 hours, then cool down to 55°C, add 12.4g of glacial acetic acid, and neutralize for 0.5 hours.

[0078] Detected by GPC, the above-mentioned fatty alcohol polyoxyb...

Embodiment 2

[0082] This embodiment relates to a kind of fatty alcohol polyoxybutylene ether polyglyceryl ether, which is prepared according to the following steps:

[0083] S1. Preparation of fatty alcohol polyoxybutylene ether: Weigh 130.23g (1mol) of isooctyl alcohol and 16.7g of sodium hydroxide into the reaction kettle, turn on the vacuum, dehydrate for 0.7 hours, pass in nitrogen, add 432.66g (6mol) of epoxy Butane, react at a temperature of 130°C until the pressure is constant, cool down to 100°C after aging for 1.5 hours, and obtain fatty alcohol polyoxybutylene ether;

[0084] S2. Preparation of fatty alcohol polyoxybutylene ether polyglyceryl ether: Add 1111.2 g (15 mol) of glycidol dropwise to fatty alcohol polyoxybutylene ether at a temperature of 100° C. for 4 hours, and continue after the addition Keep warm for 2 hours, then cool down to 55°C, add 25.1g of glacial acetic acid, and neutralize for 1 hour.

[0085] Detected by GPC, the above-mentioned fatty alcohol polyoxybutyl...

Embodiment 3

[0089] This embodiment relates to a kind of fatty alcohol polyoxybutylene ether polyglyceryl ether, which is prepared according to the following steps:

[0090] S1. Preparation of fatty alcohol polyoxybutylene ether: Weigh 130.23g (1mol) of isooctyl alcohol and 23.3g of potassium methylate into the reaction kettle, turn on the vacuum dehydration for 1 hour, pass in nitrogen, and add 721.1g (10mol) of butylene oxide , react at a temperature of 135°C until the pressure is constant, cool down to 100°C after aging for 1.5 hours, and obtain fatty alcohol polyoxybutylene ether;

[0091] S2. Preparation of fatty alcohol polyoxybutylene ether polyglyceryl ether: Add 1481.6g (20mol) glycidol dropwise to fatty alcohol polyoxybutylene ether at a temperature of 120°C for 8 hours, and continue after the addition Keep warm for 2 hours, cool down to 55°C, add 20.0g of glacial acetic acid, and neutralize for 1 hour.

[0092] Detected by GPC, the above-mentioned fatty alcohol polyoxybutylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com