Metal degreasing agent

A metal degreasing and fat technology, applied in the field of cleaning agents, can solve problems such as poor anti-rust performance, increase the manufacturing cost of compressors, destroy refrigerants, etc., and achieve strong anti-rust ability, strong defoaming performance, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

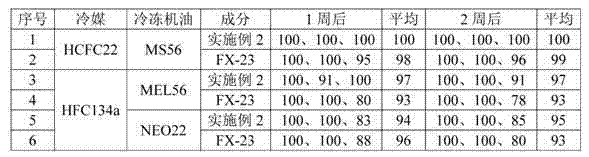

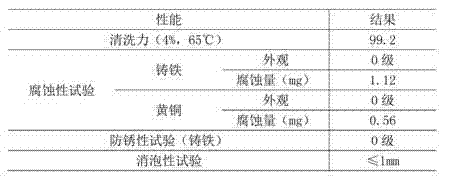

Examples

Embodiment 1

[0026] Metal degreasing agent, containing sodium carbonate 11%, capric acid diethanolamine 4%, fatty alcohol polyoxyethylene ether 6%, polyoxyethylene polyoxypropylene monobutyl ether 3%, benzotriazole 0.7%, and the balance is water.

Embodiment 2

[0028] Metal degreasing agent, containing sodium carbonate 13%, capric acid diethanolamine 5%, fatty alcohol polyoxyethylene ether 4%, polyoxyethylene polyoxypropylene monobutyl ether 2%, benzotriazole 0.5%, and the balance is water.

Embodiment 3

[0030] Metal degreasing agent, containing 9% sodium carbonate, 6% capric acid, 4% fatty alcohol polyoxyethylene ether, 1.5% polyoxyethylene polyoxypropylene monobutyl ether, 1% benzotriazole, and the balance is water .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com