Track hanging conveyor

A technology of conveyors and track cranes, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of difficult steering of the conveyor system, high energy consumption of conveyors, and large running resistance, so as to achieve obvious energy saving effects and avoid interruptions. The effect of bringing accidents and eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

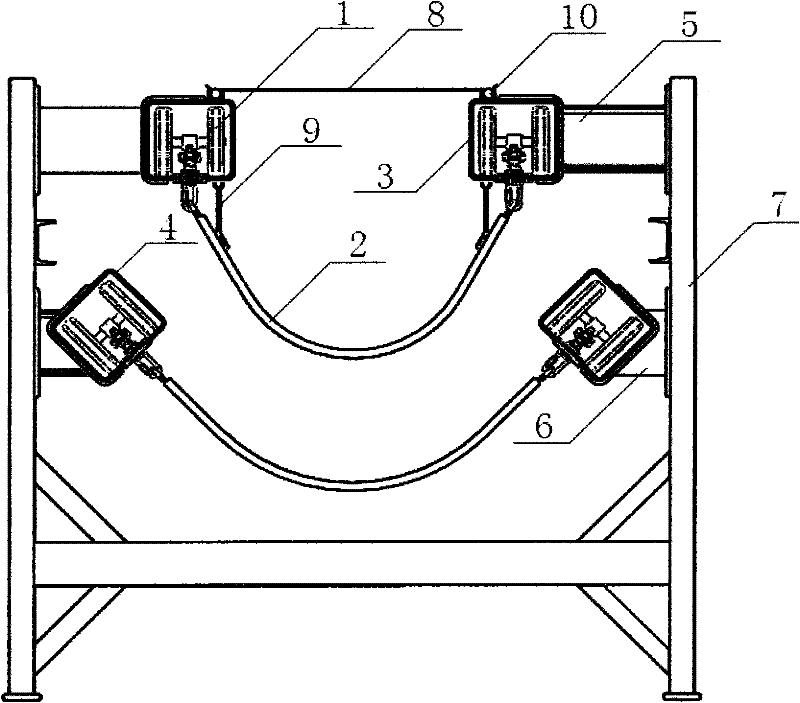

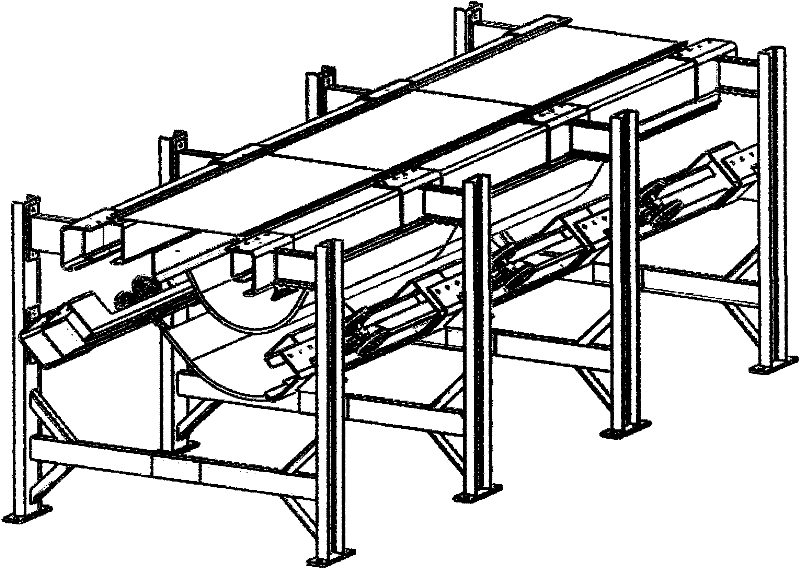

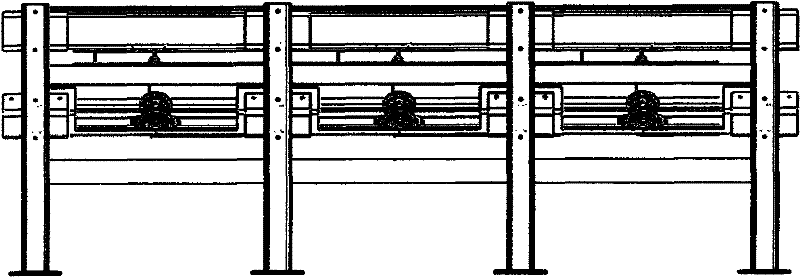

[0036] figure 1 , figure 2 and image 3 The schematic diagrams of different perspectives of the running section of the track-mounted conveyor are shown in the figure respectively. figure 1 Among them, the running section is fixed by a hanging pulley block (1), a hanging conveyor belt (2), a box-type guide rail (3), an open box-type guide rail (4), a vertical guide rail fixing frame (5), and an oblique guide rail frame (6), conveyor frame assembly (7), dust cover (8), rubber baffle assembly (9), and fixing strip assembly (10). The opening of the slot is downward, and the two rails are installed symmetrically and parallel. Figure 5 The closed box-type guide rail shown in the figure is in the shape of a rectangular tube, which is formed by folding steel plates. The 24 marked in the figure is the walking track (24), and the interval betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com