904L stainless steel welding method

A welding process, stainless steel technology, applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve the problems of prolonging the service life of welded parts, thermal cracks, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

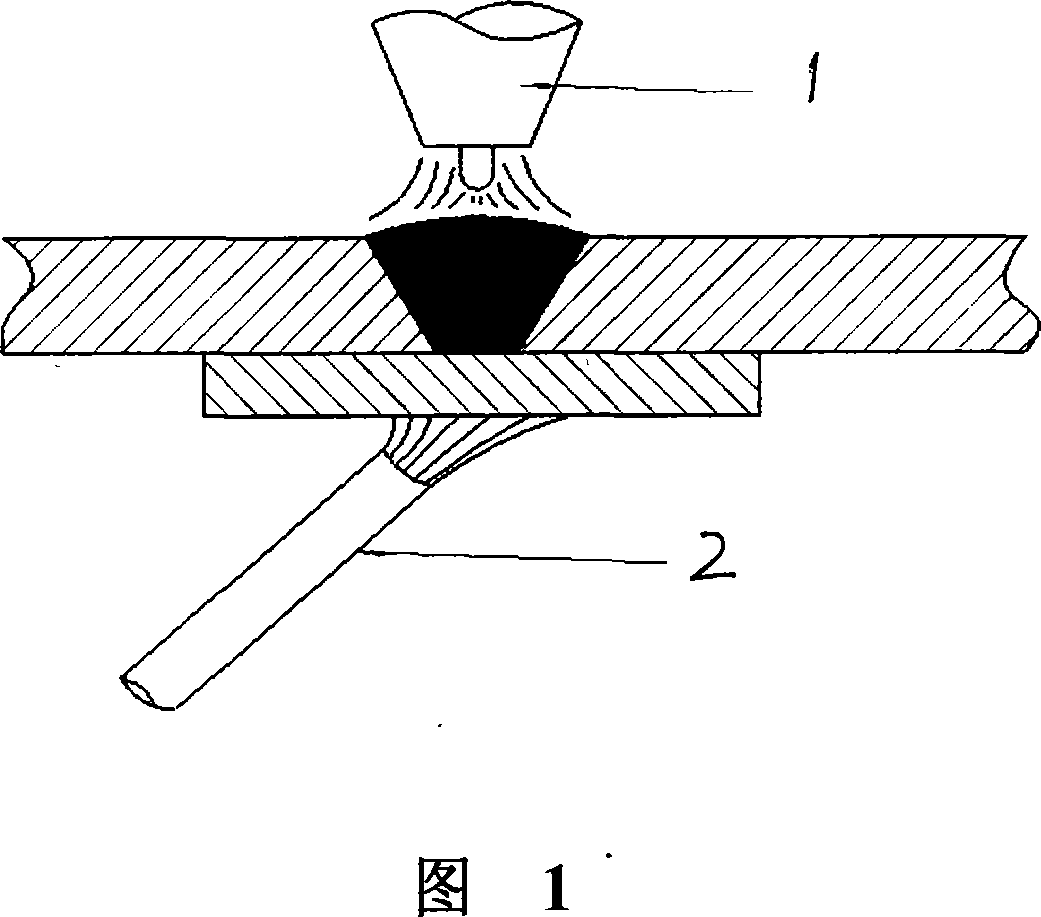

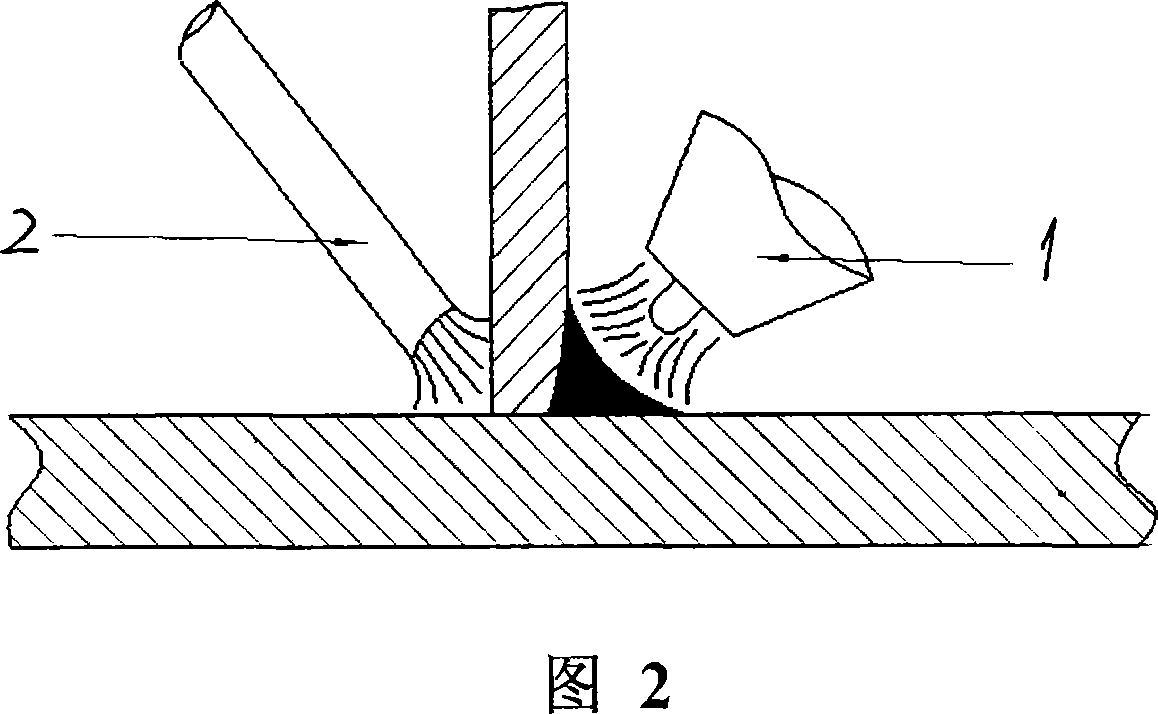

Image

Examples

Embodiment 1

[0019] The concrete welding example of the second bath tank that 904L stainless steel of the present invention makes:

[0020] The operation method is as follows:

[0021] 1. Machine tools and welding materials

[0022] (1) The welding equipment selects an inverter welding machine with good characteristics.

[0023] (2) Oil, dirt, burrs, etc. on the surface of the argon arc welding wire should be removed before use.

[0024] 2. Preparation before welding

[0025] (1) Cleaning: The production and preparation of edges or grooves generally adopt mechanical processing methods, and the welding seam should be cleaned with acetone within the range of 20-30mm.

[0026] (2) Butt joint assembly: welding wire of the same material as the weldment should be used for spot fixing before welding or clamped with clamps. That is, welding or spot welding must use welding wire that matches the base metal or strips cut from the base metal as welding wire.

[0027] (3) Narrow weld bead must be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com