Hot melting device and hot melting method thereof

A hot-melting machine and hot-melting technology, applied in the field of hot-melting machines, can solve the problems of many melting point burrs and waste of energy, and achieve the effects of obvious energy saving, long service life and low welding temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

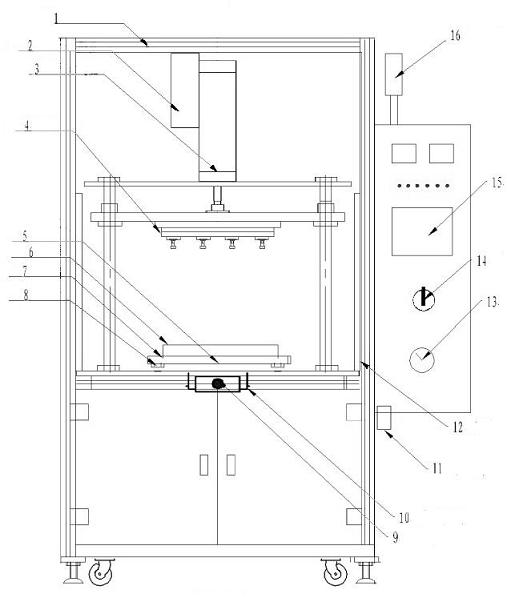

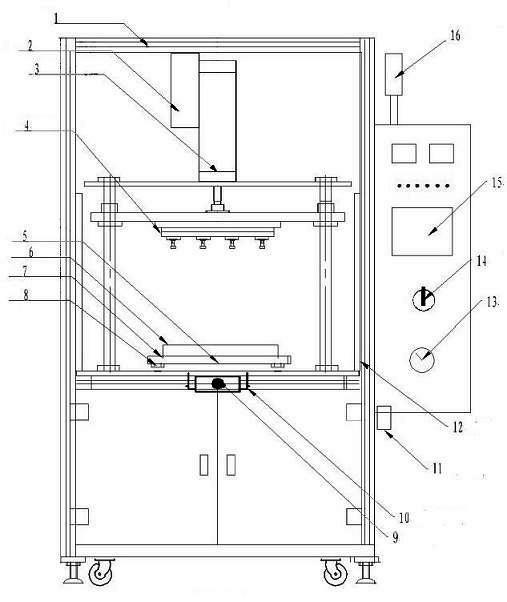

[0021] Below in conjunction with accompanying drawing, the present invention is further described in detail:

[0022] The invention relates to a hot-melt machine with a new structure, which includes a cabinet, wheels and fixed feet are arranged at the bottom of the cabinet, which is convenient for the handling and fixing of the machine, and a frame 1 is arranged on the upper side of the cabinet, and the top surface of the cabinet A pair of linear guide rails 8 are set, and a mobile workbench 7 is arranged on the linear guide rails 8. In this way, the mobile workbench 7 can move forward and backward along the linear guide rail 8, and a clamp 6 is set on the mobile workbench 7. . On the upper part of the frame 1, set a moving cylinder 3 up and down, one end of the moving cylinder 3 is connected to the frame 1, and the other end is connected to the hot mold 4, the hot mold 4 is a rectangular flat plate, and several components are arranged on the lower side of the flat plate. Typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com