Pressurizing device and method for vacuum diffusion welding machine

A technology of vacuum diffusion welding and pressure device, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low welding efficiency, high welding temperature, and incompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

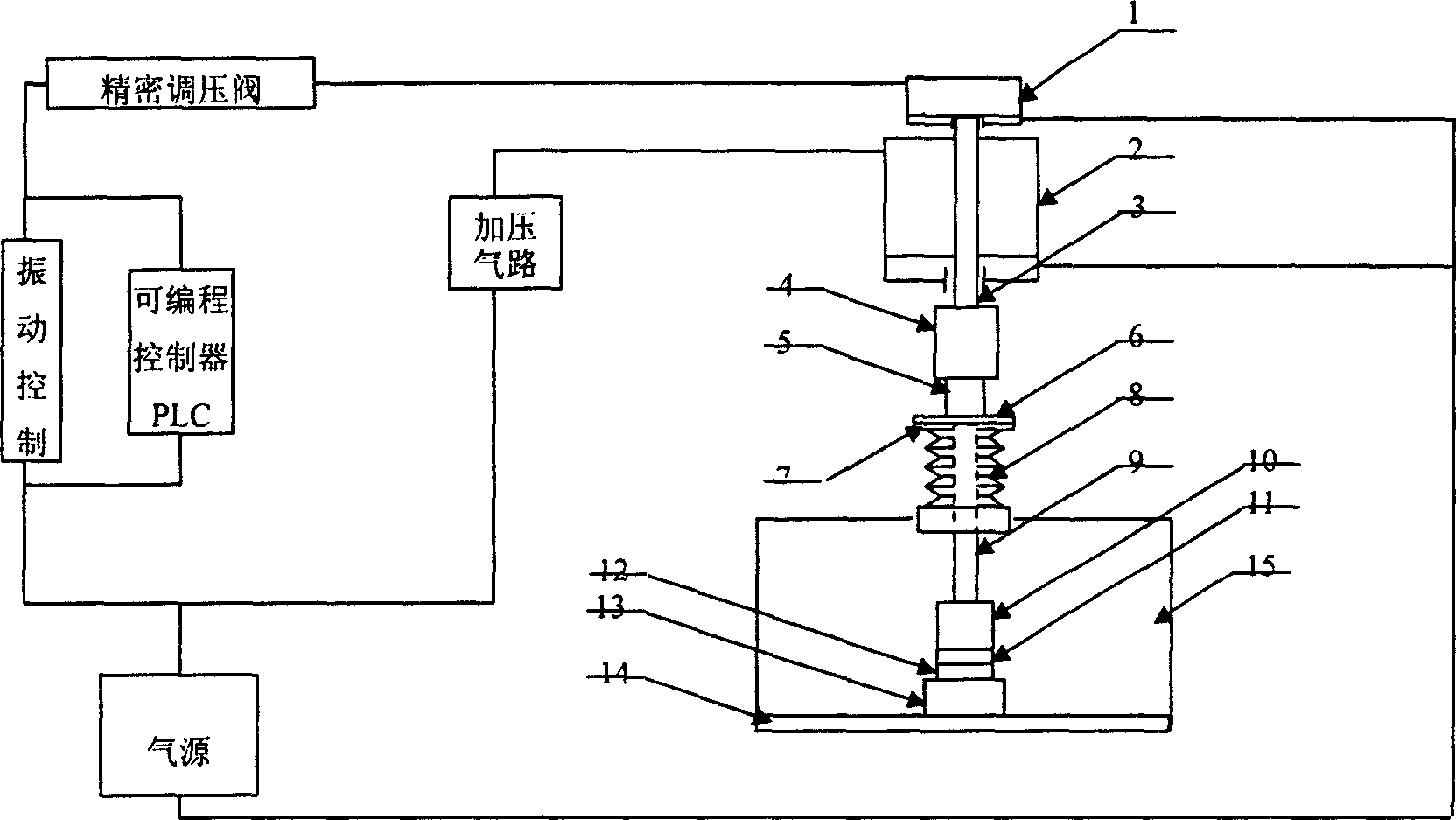

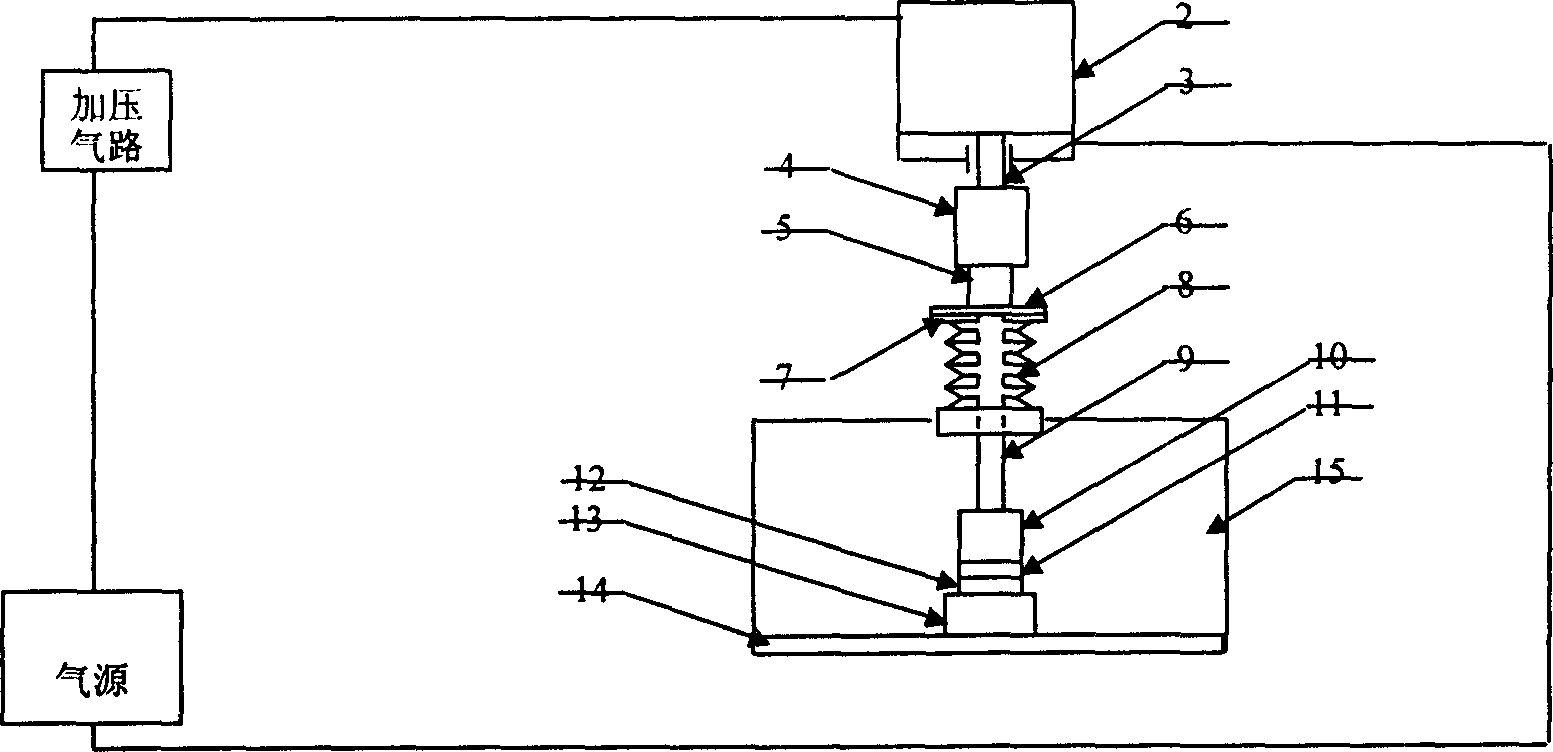

[0019] refer to figure 1 . The pressurized actuator consists of a pressurized cylinder 2 that can apply static load or quasi-static load pressure and a vibration cylinder 1 that can apply impact pressure in series. That is, the vibrating cylinder 1 is above the pressurized cylinder 2, and the two share an upper pressurized shaft 3.

[0020] The upper pressurized shaft 3 shared by the vibration cylinder 1 and the pressurized cylinder 2 is rigidly connected to the upper end of the pressure sensor 4 through threads, the lower end of the pressure sensor 4 is connected to the top boss 5 of the upper flange through threads, and the lower flange 7 is integrated with the bellows 8. At the same time, the lower pressurization shaft 9 is fixed inside the upper flange 6 , and the lower pressurization shaft 9 passes through the bellows 8 and extends into the vacuum chamber 15 .

[0021] In order to prevent dislocation and deflection of the joint to be welded during the vibration pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com