Two-step hot isostatic pressing diffusion welding method for tungsten target assembly

A technology of hot isostatic pressing diffusion and welding method, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of high welding strength, high welding strength, and low welding strength, so as to reduce deformation, The effect of high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

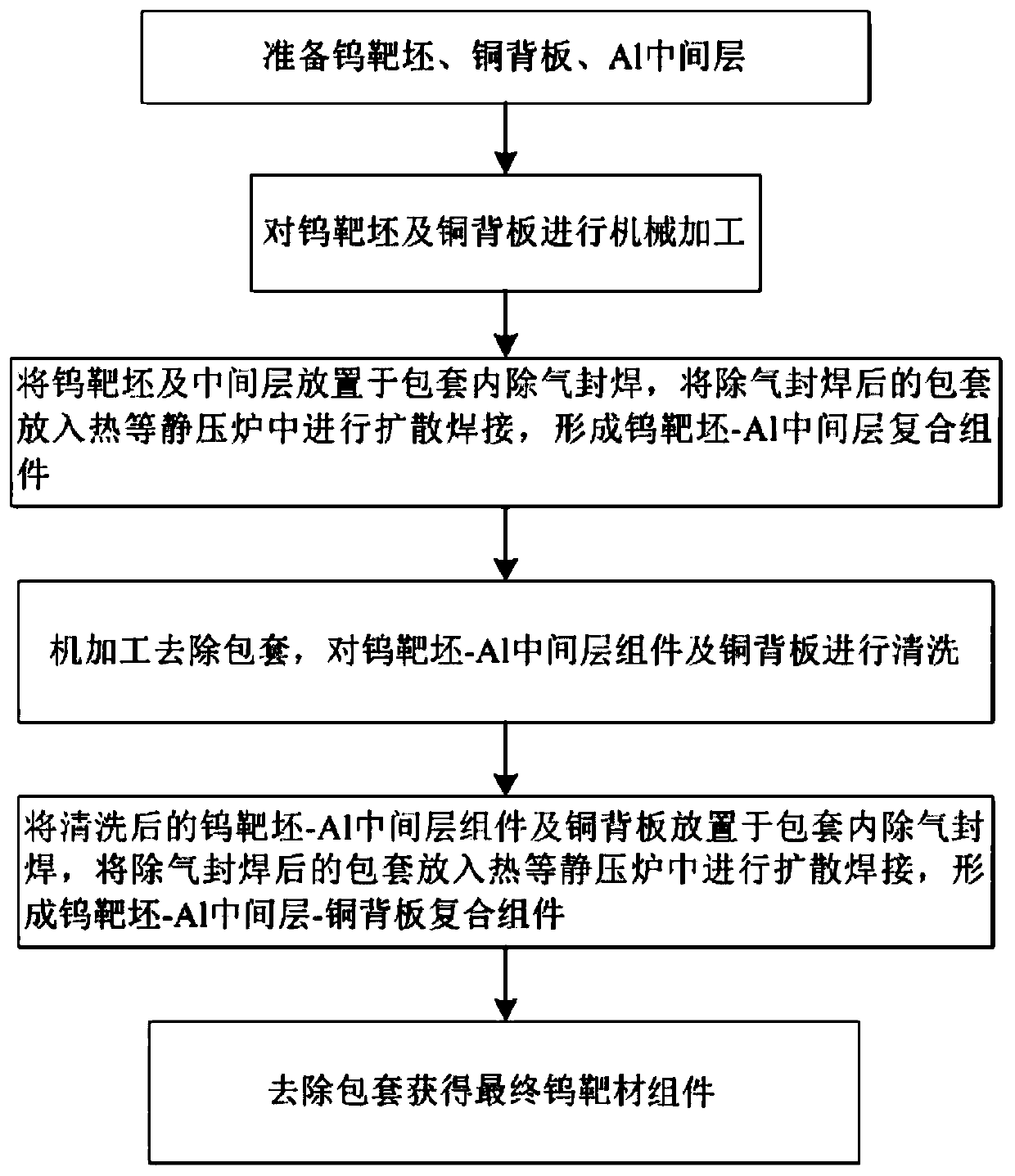

[0027] 1. Prepare the required tungsten target blank, copper back plate and Al intermediate layer.

[0028] 2. Machining: Machining the tungsten target blank and the copper back plate, so as to improve the welding bonding ability between the tungsten target blank, the Al intermediate layer and the copper back plate.

[0029] 3. Cleaning: Ultrasonic cleaning is performed on the machined tungsten target blank and the Al intermediate layer.

[0030] 4. Degassing sealing welding: put the cleaned tungsten target blank and Al intermediate layer into the Al sheath for degassing sealing welding.

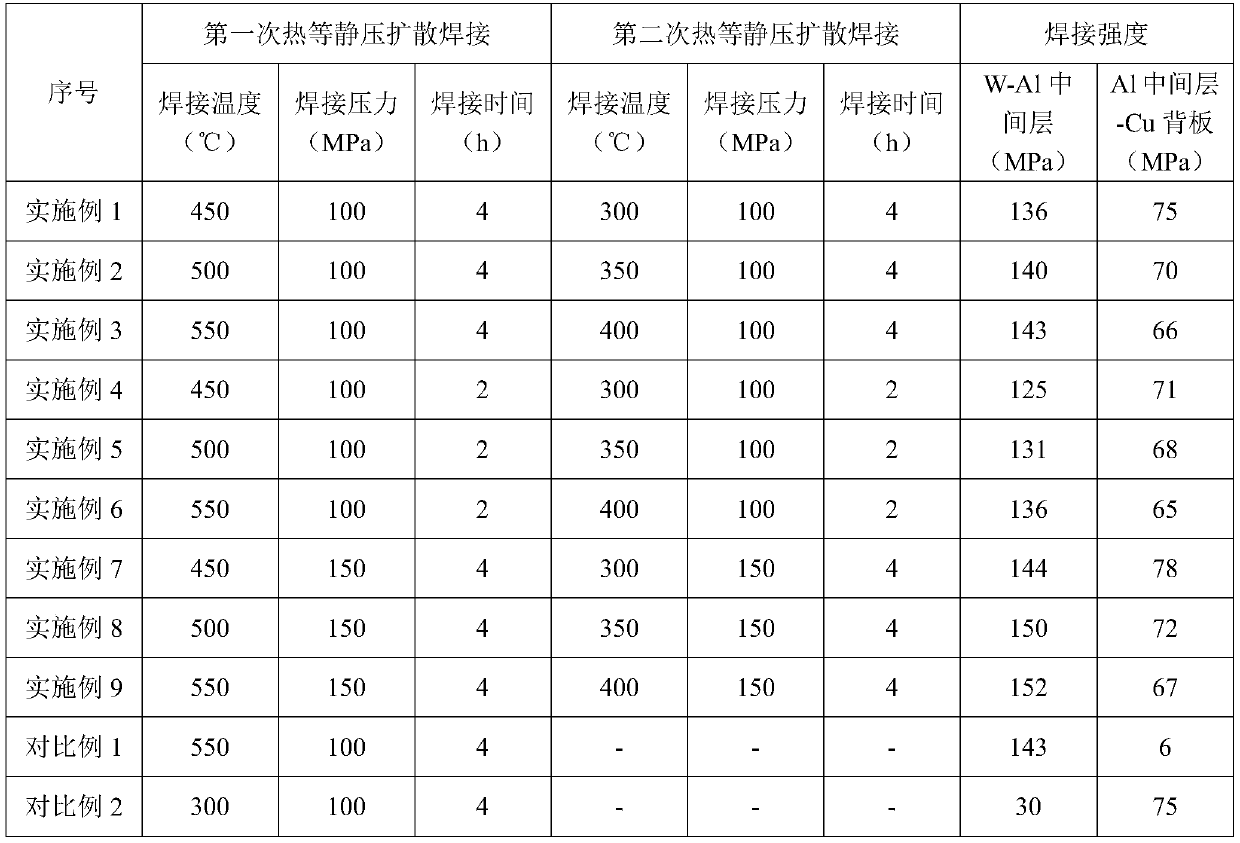

[0031] 5. The first step of hot isostatic pressure diffusion welding: put the tungsten target blank and Al intermediate layer sample after degassing and sealing welding into the hot isostatic pressing furnace for hot isostatic pressure diffusion welding, the welding temperature is 450 ° C ~ 550 ° C ℃, the welding pressure is 100-150MPa, and the welding time is 2-4h. A tungsten target blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com