Multi-unit synthesis type reflector based method for manufacturing power type light emitting diode

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult production of power-type vertical light-emitting diodes, large thermal strain, etc., achieve high yield, ensure welding strength, and improve luminous efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] A method for manufacturing a power-type light-emitting diode based on a multi-unit synthetic reflector, the steps of which are as follows:

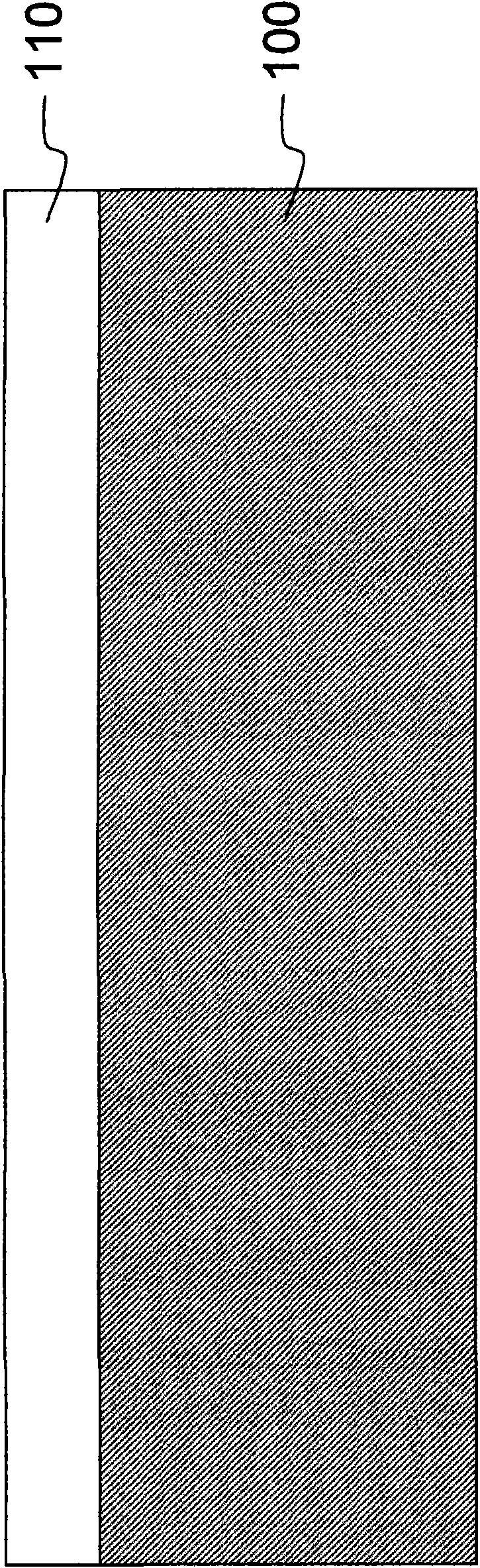

[0035] Step 1: If Figure 1a As shown, a GaN-based LED luminescent material 110 is epitaxially grown on a sapphire substrate 100 by MOCVD method, and the luminescent material sequentially includes an n-type GaN-based semiconductor layer, an active layer and a p-type GaN-based semiconductor layer;

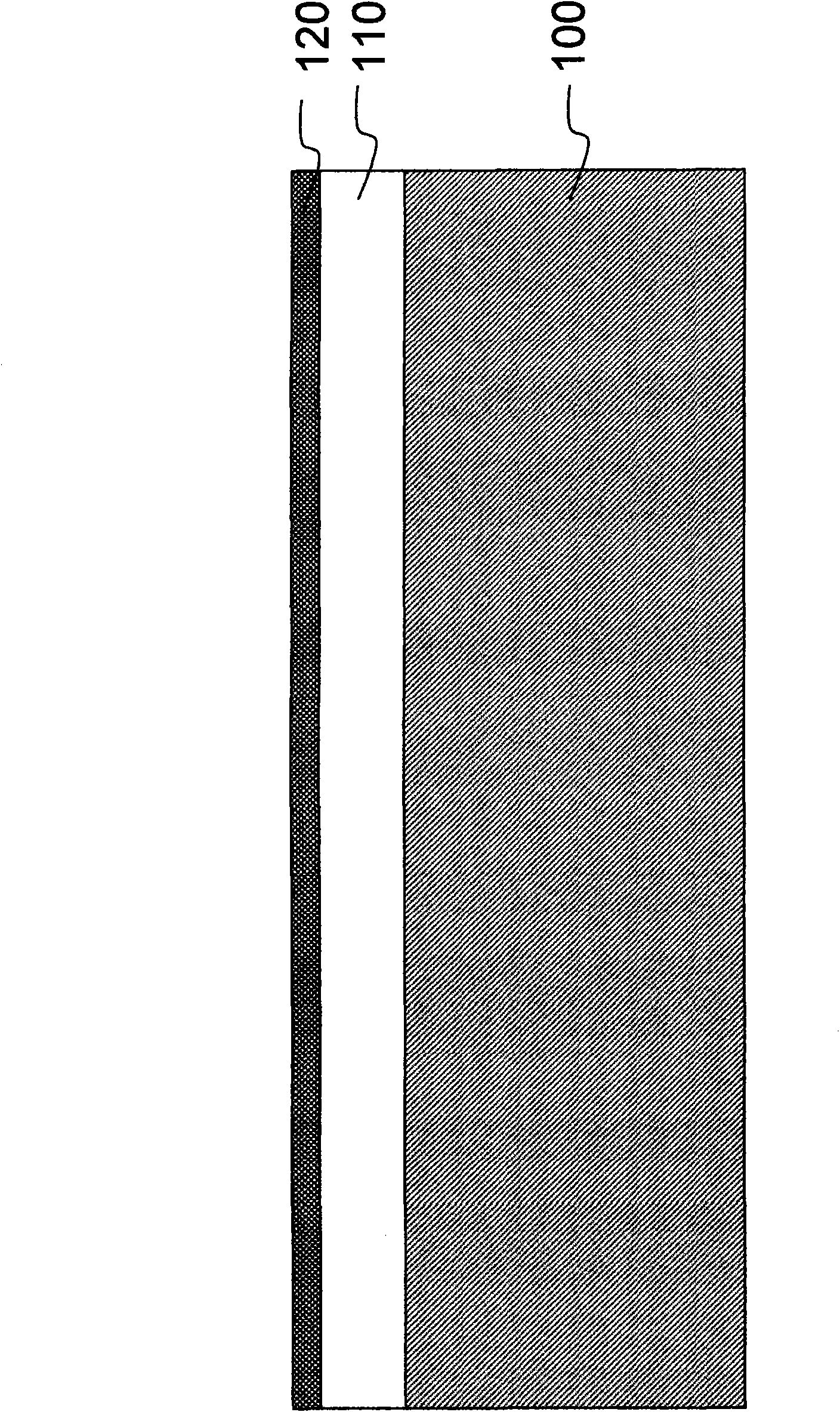

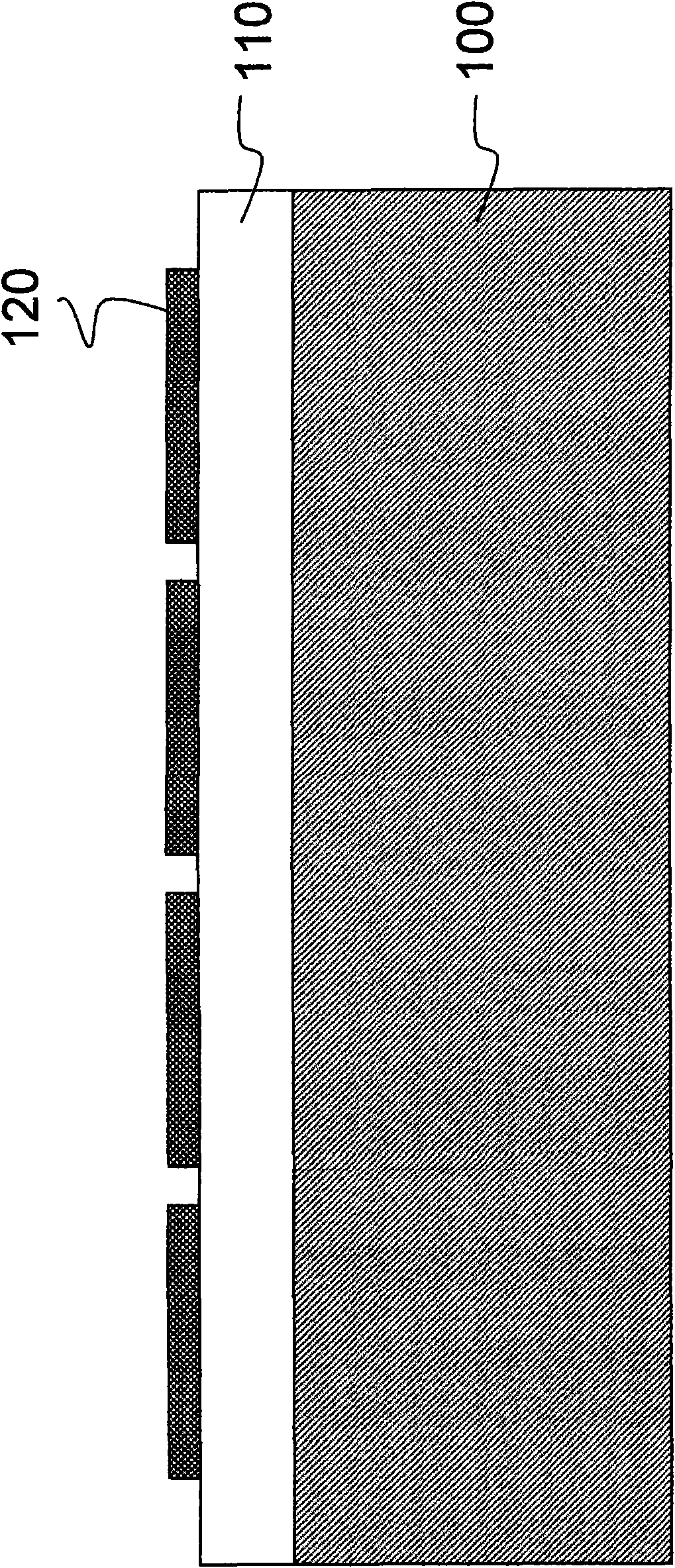

[0036] Step 2: If Figure 1b As shown, electron beam evaporation is used to deposit p metal and reflective metal film 120 on the surface of p-type GaN-based semiconductor layer, Ag is selected, and the thickness is 1000nm; Figure 1c As shown in Fig. 1, chemical etching is used to remove the Ag reflective metal film in the surrounding area of each periodic device and the central part of the periodic device, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com