Method for T-shaped magnesium alloy section friction stir welding

A technology of friction stir welding and welding method, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of low connection strength, and achieve the effects of strong thickness adaptability, high efficiency, and small heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

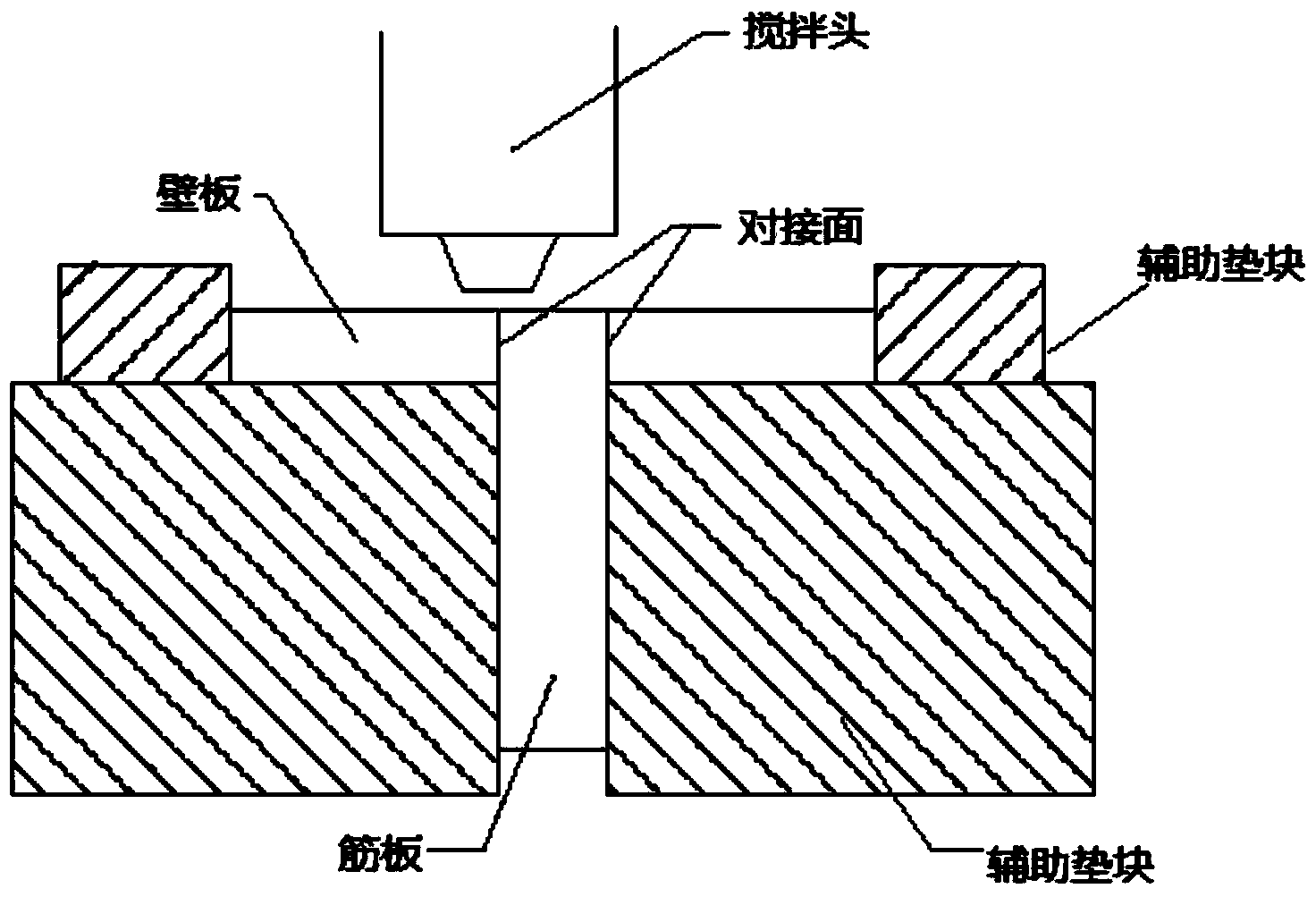

Embodiment 1

[0027] The 12mm thick AZ31 magnesium alloy is subjected to friction stir T-welding. The size of the two wall plates is 290mm×115mm×12mm, the size of the rib plate is 290mm×230mm×12mm, and the tensile strength of the base metal (magnesium alloy) is 268MPa. The shaft shoulder of the stirring head used is in the shape of a double concave ring with a diameter of 24mm; the stirring needle is a tapered right-handed thread with a diameter of 5-7mm and a length of 11.7mm. Butt and fix the three plates to be welded on the backing plate with auxiliary pads, and then use the tooling to clamp the auxiliary pads of the wall plate, the three magnesium alloy profiles to be welded and the auxiliary pads of the rib plate laterally on the welding workbench superior. When welding starts, the stirring head is inserted into the butt surface of the wall plate and the rib plate at an insertion speed of 20mm / min, and the pressing amount of the shaft shoulder is 0.2mm, and stays for 2s; when starting ...

Embodiment 2

[0030] The 8mm thick AZ31 magnesium alloy is subjected to friction stir T-welding. The size of the two wall plates is 230mm×90mm×8mm, the size of the rib plate is 230mm×180mm×8mm, and the tensile strength of the base metal is 268MPa. The shaft shoulder of the stirring head used is in the shape of a double concave ring with a diameter of 22 mm; the stirring needle is a tapered right-handed thread with a diameter of 3-5 mm and a length of 7.7 mm. Butt and fix the three plates to be welded on the backing plate with auxiliary pads, and then use the tooling to clamp the auxiliary pads of the wall plate, the three magnesium alloy profiles to be welded and the auxiliary pads of the rib plate laterally on the welding workbench superior. When welding starts, the stirring head is inserted into the butt surface of the wall plate and the rib plate at an insertion speed of 20mm / min, and the pressing amount of the shaft shoulder is 0.2mm, and stays for 2s; when starting to move, keep the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com