Low-temperature halogenide-free high-activity soldering tin paste

A technology of solder paste and halide, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of multi-corrosion residue, destruction of atmospheric ozone layer, and influence on product reliability, etc., to achieve long-term benefits Effects of time printing, life extension, and suppression of solder ball formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative Embodiment 1~2

[0032] The spherical powder of 88.5% Sn-Bi based lead-free solder alloy having the following composition: 42% Sn and 58% Bi, the rosin-based flux had the composition shown in Table 1. Each component is weighed in proportion, heated and dissolved to form a homogeneous solution, and stored at 5-10°C for later use.

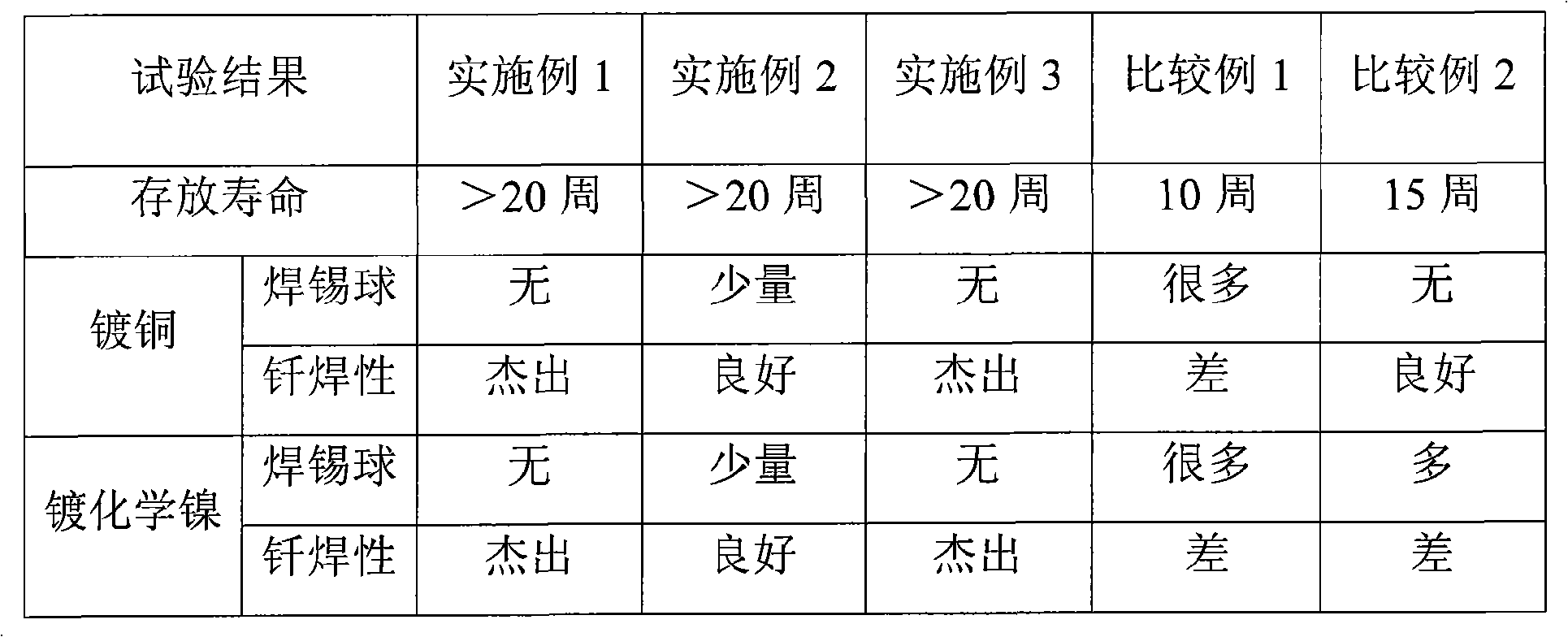

[0033] Using the solder paste prepared above, a soldering test was carried out in a standard tin melting furnace, and the solderability (wettability) and the formation of solder balls were evaluated. The coating materials were copper plating and electroless nickel plating, respectively. The results are shown in Table 2

[0034] Table 1 flux formulation table

[0035] Flux composition, %

Example 1

Example 2

Example 3

Comparative example 1

Comparative example 2

polymerized rosin

50

48

48

46

48

Diethylene glycol hexyl ether

36

36

36

36

36

3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com