Silver dust and manufacturing method thereof

A technology of silver powder and particle size distribution, which is applied in the manufacture of cables/conductors, metal/alloy conductors, conductors, etc., can solve the problems of no suppression related proposals, dispersibility, and flake production, and achieve excellent uniformity, Viscosity change suppression, the effect of suppressing the occurrence of flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] 2492 g of silver chloride (manufactured by Sumitomo Metal Mining Co., Ltd.) was thrown into 36 L of 25% ammonia water kept at 36° C. in a warm bath at 38° C. while stirring to prepare a silver complex solution. The defoamer (manufactured by ADEKA CORPORATION, Adekanol LG-126) was diluted to 100 times by volume, and 24.4ml of the defoamer dilution was added to the above-mentioned silver complex solution, and the resulting silver complex solution was The warm bath was maintained at 36°C.

[0128] On the other hand, 1068 g of ascorbic acid (manufactured by Kanto Chemical Co., Ltd., reagent, 56.9% by mass relative to silver particles) as a reducing agent was dissolved in 13.56 L of pure water at 36° C. to prepare a reducing agent solution. Next, 159.5 g of polyvinyl alcohol as a water-soluble polymer (manufactured by Kuraray Co., Ltd., PVA205, 8.5% by mass relative to silver) was dissolved in 1 L of pure water at 36°C to prepare a solution, and the solution was Mix in redu...

Embodiment 2

[0145] Silver powder was produced in the same manner as in Example 1 above except that the usage-amount of polyvinyl alcohol as a water-soluble polymer was 65.7 g (Kuraray Co., Ltd. product, PVA205, 3.5 mass % with respect to silver particles).

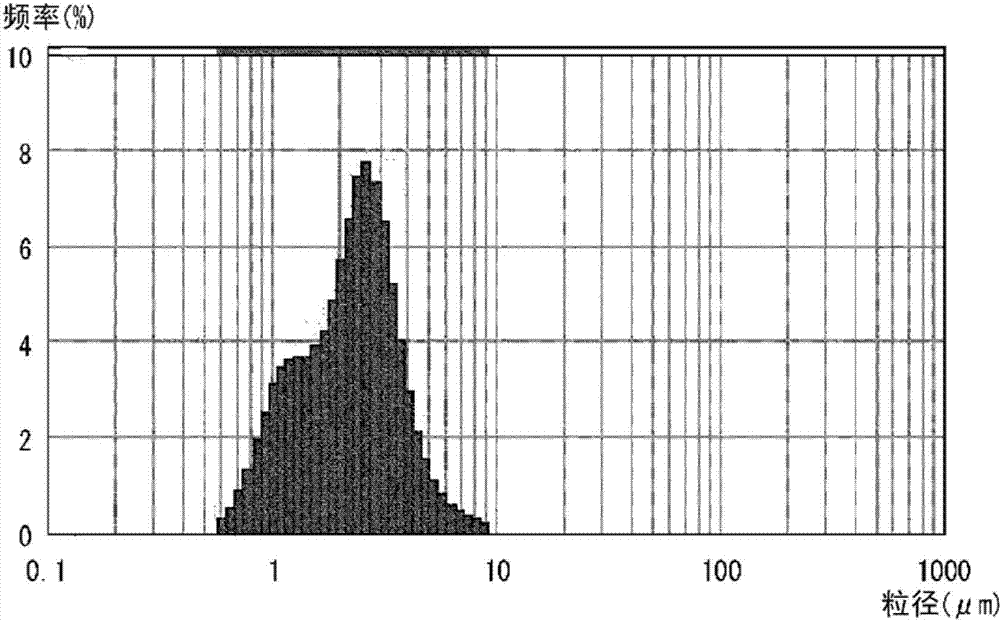

[0146] The obtained silver powder was evaluated in the same manner as in Example 1 above. As a result, the obtained particle size distribution was shown in Figure 4 , and the respective values are shown in Table 1 below.

[0147] In addition, using the obtained silver powder, a homogeneous kneaded product was produced with a self-revolving kneader (ARE-250 type manufactured by THINKY CORPORATION), and evaluated in the same manner as in Example 1. The obtained particle size distribution is shown in Figure 5 , and the obtained values are shown in Table 1 below.

[0148] Such as Figure 4 , Figure 5 As shown, the particle size distribution is in the region of 0.3μm~14.0μm, and the peak P 1 with shoulder P 2 The relationship i...

Embodiment 3

[0154] The amount of polyvinyl alcohol used as a water-soluble polymer was 262.8 g (Kuraray Co., Ltd., PVA205, 14.0% by mass relative to the silver particles), and the pulverization conditions were 5 L high-speed mixer (NIPPON COKE & ENGINEERING CO., LTD., FM5C) was stirred at a peripheral speed of 33 m / s for 30 minutes, and the silver powder was produced in the same manner as in the above-mentioned Example 1 except that it was decompressed and pulverized by a vacuum pump.

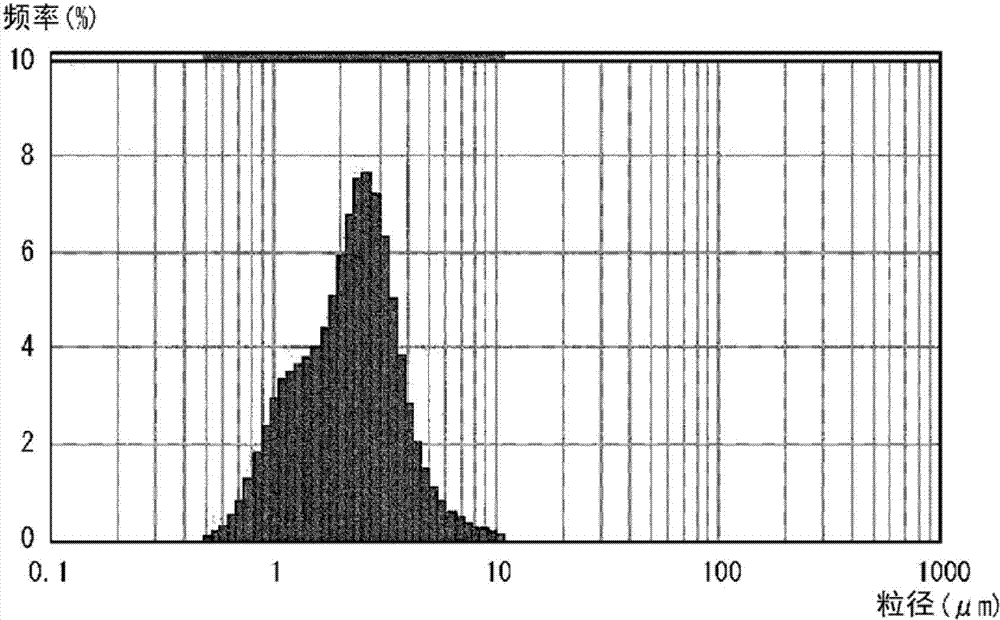

[0155] The obtained silver powder was evaluated in the same manner as in Example 1 above. As a result, the obtained particle size distribution was shown in Image 6 , and the respective values are shown in Table 1 below.

[0156] In addition, using the obtained silver powder, a homogeneous kneaded product was prepared with a self-revolving kneader (ARE-250 type manufactured by THINKY CORPORATION), and evaluated in the same manner as in Example 1. The obtained particle size distribution is shown in Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com