Brown concocted concentrated milk and preparation method thereof

A technology for preparing condensed milk and browning, which is applied in the field of browning condensed milk and its preparation. It can solve the problems of not prominent burnt aroma, high viscosity of condensed milk, and only sweet aroma of condensed milk products, so as to achieve good flavor, reduce fat content, and ensure Effect of Maillard Reaction Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing brown modulated condensed milk, comprising the following steps:

[0037] 1) Dissolving milk powder: Prepare whole milk, heat up to 38°C-42°C, add whole milk powder and buttermilk powder to dissolve;

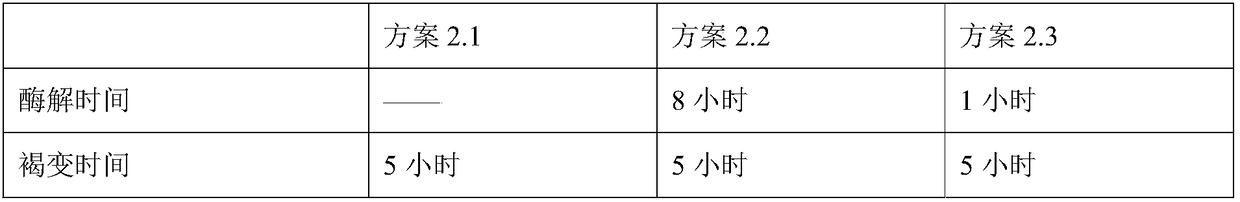

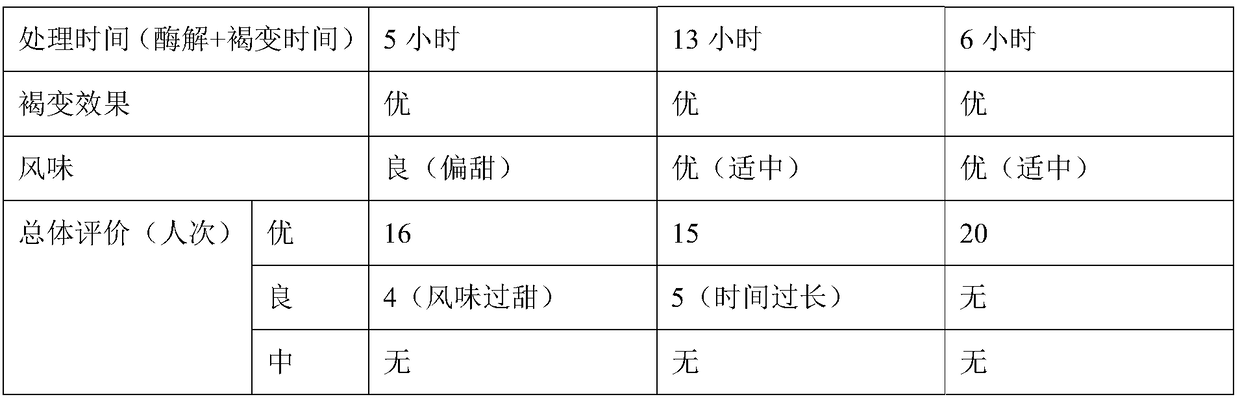

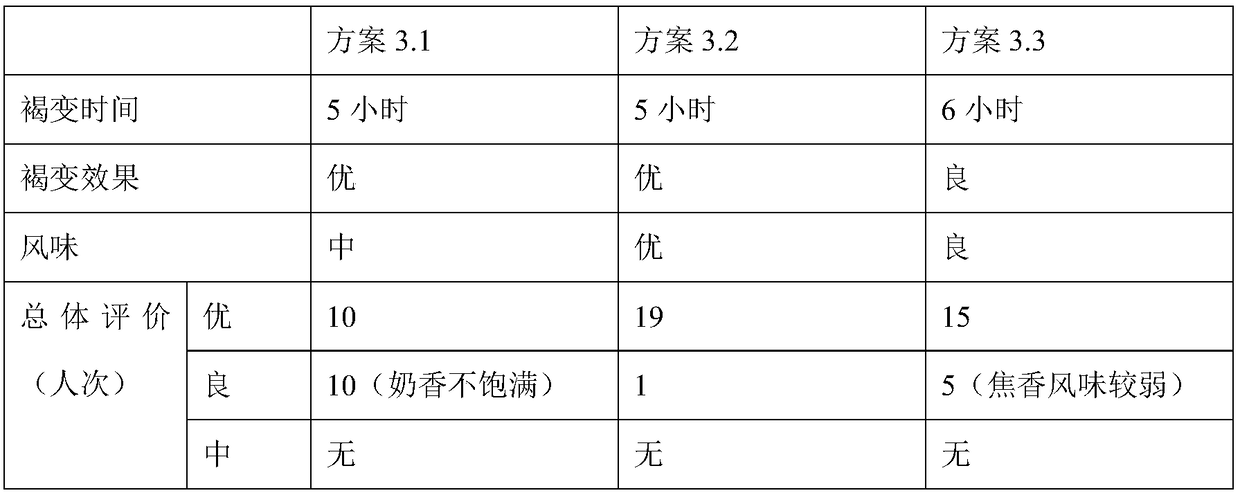

[0038] 2) Lactose hydrolysis: add lactase to the milk in step 1), and keep the milk temperature at 38°C-42°C for enzymatic hydrolysis;

[0039] 3) Heating browning: heat up the material in step 2) to 95°C to 98°C and keep warm until the material is completely browned;

[0040] 4) Add cream: add cream to the material in step 3), and mix well;

[0041] 5) Homogenization and sterilization: homogenize and sterilize the material obtained in step 4);

[0042] 6) Disinfection of sugar liquid: add white granulated sugar into hot water at 95°C to 100°C to dissolve, keep warm, and obtain white granulated sugar liquid;

[0043] 7) Concentration: Concentrate the milk liquid obtained in step 5) to a water mass content of 40% to 50%, add the white granulated su...

Embodiment 1

[0060] The preparation method of embodiment 1 brown modulation condensed milk, comprises the following steps:

[0061] 1) Dissolving milk powder: prepare whole milk, heat up to 40°C, add whole milk powder and buttermilk powder to dissolve;

[0062] 2) Lactose hydrolysis: add lactase to the milk in step 1), and keep the temperature of the milk at 40°C for enzymatic hydrolysis for 60 minutes;

[0063] 3) Heating browning: heat up the material in step 2) to 96° C. and keep it warm for 5 hours, until the material is completely browned and the color is dark brown;

[0064] 4) Add cream: add cream to the material in step 3), and mix well;

[0065] 5) Homogenization sterilization: homogenize and sterilize the material obtained in step 4) at 180 bar, wherein the sterilization temperature is 105°C, the sterilization time is 6s, and the sterilization outlet temperature is 60°C;

[0066] 6) Disinfection of the sugar solution: add white granulated sugar to 98°C hot water to dissolve, th...

Embodiment 2

[0072] The preparation method of embodiment 2 brown modulating condensed milk, comprises the following steps:

[0073] 1) Dissolving milk powder: prepare whole milk, heat up to 38°C, add whole milk powder and buttermilk powder to dissolve;

[0074] 2) Lactose hydrolysis: add lactase to the milk in step 1), and keep the temperature of the milk at 38°C for enzymatic hydrolysis for 75 minutes;

[0075] 3) Heating browning: heat up the material in step 2) to 98° C. and keep it warm for 3 hours, until the material is completely browned and the color is dark brown;

[0076] 4) Add cream: add cream to the material in step 3), and mix well;

[0077] 5) Homogenization sterilization: homogenize and sterilize the material obtained in step 4) at 160 bar, wherein the sterilization temperature is 108°C, the sterilization time is 4s, and the sterilization outlet temperature is 70°C;

[0078] 6) Disinfection of the sugar solution: add white granulated sugar to 99°C hot water to dissolve, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com