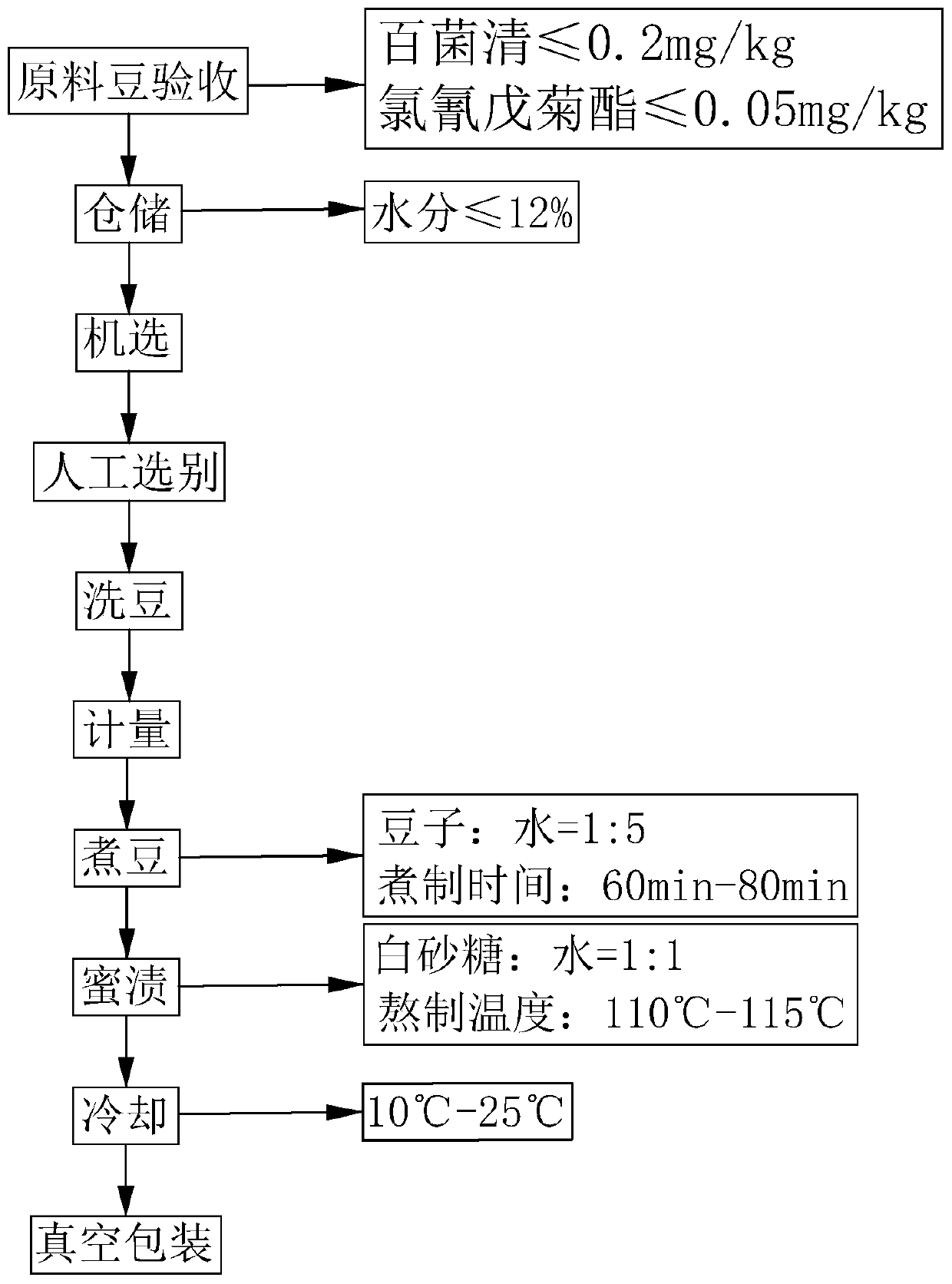

Production process of sweet natto

A production process, the technology of natto, which is applied in the direction of food science, etc., can solve problems such as deviation, the influence of sweetness of natto, and increase the water content of beans to achieve the effect of reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

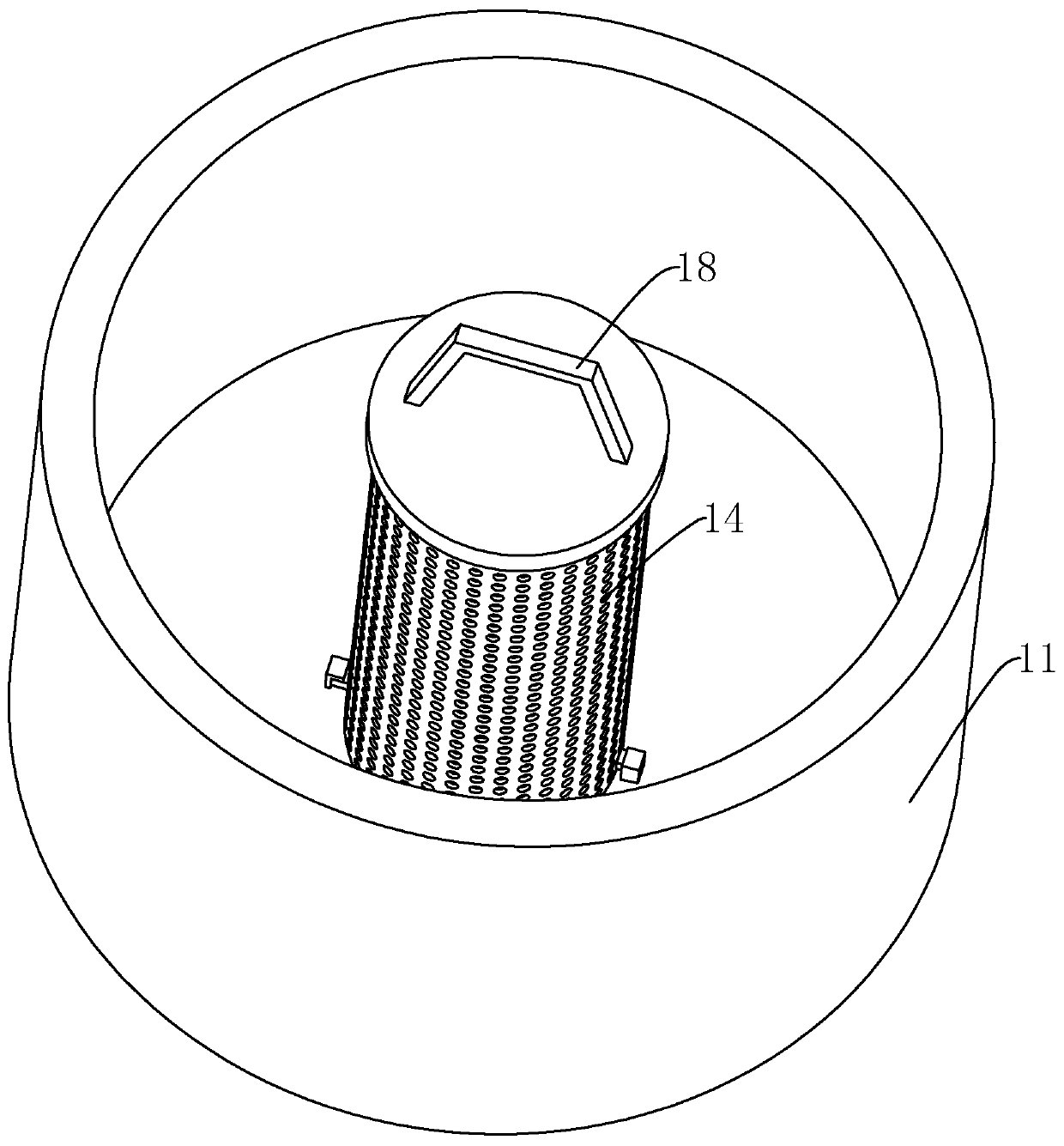

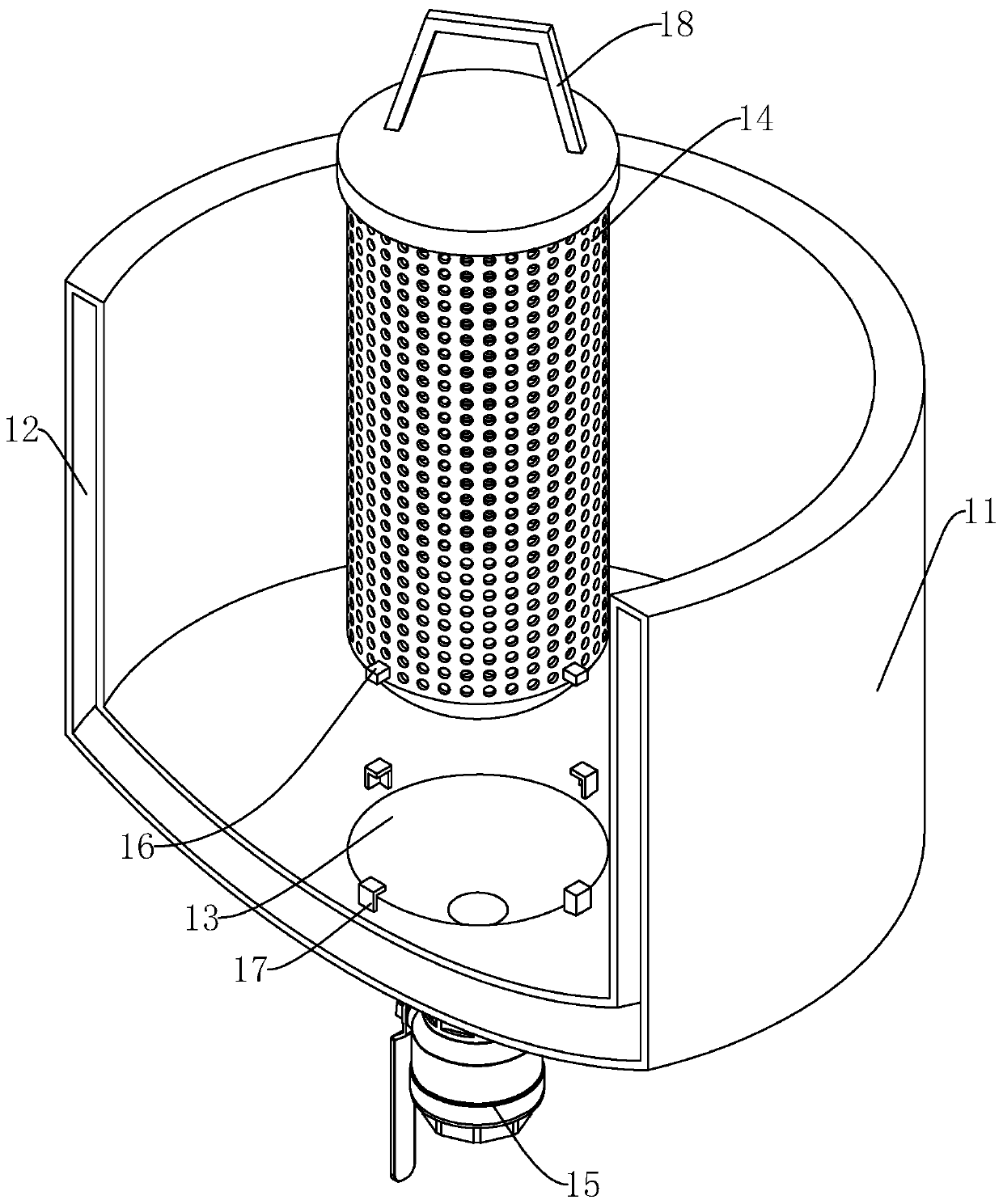

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] refer to figure 1 , is a kind of Gannatto production technology disclosed by the present invention, comprises the following steps:

[0034] Step 1: Raw material beans are received, and the specific criteria for the acceptance of raw material beans are as follows:

[0035] Visually inspect the appearance of raw beans: the beans are round, the seed coat is smooth, and the seeds are hard;

[0036] According to the GB2763 standard, use the pesticide residue detector to detect pesticide residues. The inspection standards are as follows:

[0037] Chlorothalonil ≤0.2mg / kg, fenvalerate ≤0.05mg / kg.

[0038] Step 2: Storage. The warehouse where beans are stored should be kept dry, cool, ventilated, and the gaps everywhere should be sealed. Whitewash with 20% lime water to eliminate eggs and adults. Bean grains stored in the warehouse cannot touch the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com