Zero-sugar, zero-calorie and zero-fat crystal sugar substitute product and preparation method thereof

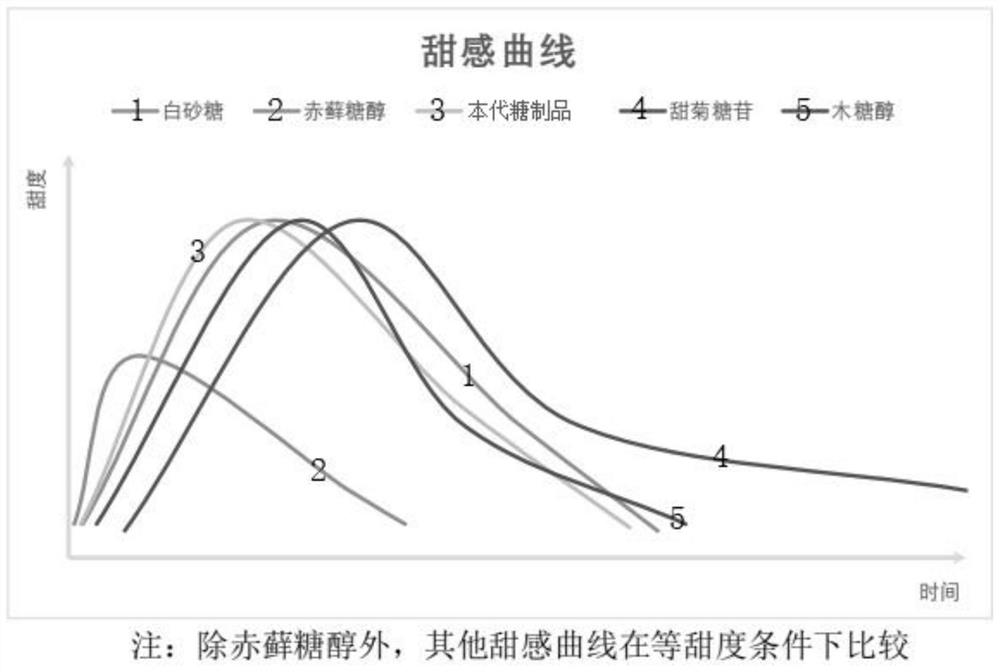

A crystal and sugar substitute technology, which is applied in the field of sugar substitute processing, can solve problems such as poor taste, poor solubility compared to white sugar, and difficulty in obtaining market approval.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: A zero-sugar, zero-calorie, and zero-fat crystalline sugar substitute product, comprising the following components in weight percent: 95% erythritol, 3% L-arabinose, 1% sucralose and 1% food flavor.

[0043] The preparation method is as follows: put 95kg of erythritol into a high-efficiency wet granulator model HLSG-100, and add 3kg of L-arabinose, 1kg of sucralose, and 1kg of food flavor to 10kg of water at 50°C to dissolve, and the temperature is 55°C, then add 10kg of 75% edible alcohol to prepare a mixed solution. Pass the mixed solution through the peristaltic pump to make the liquid spray out in the form of water mist, and stir the erythritol crystals while spraying. The stirring speed of the erythritol crystals is 30 rpm, so that the mixed solution is evenly attached to the erythritol crystals Surface: after the solution is sprayed, transfer the material to the material tray, put it into a hot air oven with a hot air temperature of 50-60°C, dry it unti...

Embodiment 2

[0044] Example 2: A zero-sugar, zero-calorie, and zero-fat crystalline sugar substitute product, comprising the following components in weight percent: 99% erythritol, 0.5% L-arabinose, 0.1% sucralose, and 0.4% food flavor.

[0045] The preparation method is as follows: put 99kg of erythritol into a high-efficiency wet granulator, and add 0.5kg of L-arabinose, 0.1kg of sucralose, and 0.4kg of edible essence to dissolve in 2kg of water at 55°C at a temperature of 60°C. Add 2kg of 75% edible alcohol to prepare a mixed solution. Pass the mixed solution through the compressed air watering can, so that the liquid is sprayed in the form of water mist, and the erythritol crystals are stirred while spraying. The stirring speed of the erythritol crystals is 35 rpm, so that the mixed solution is evenly attached to the erythritol Alcohol crystal surface; after the solution is sprayed, the material is then transferred to a material tray, and directly dried in a fluidized bed at a temperat...

Embodiment 3

[0046] Example 3: A zero-sugar, zero-calorie, and zero-fat crystalline sugar substitute product, comprising the following components in weight percent: 98.55% erythritol, 1% L-arabinose, 0.05% sucralose, and 0.4% food flavor.

[0047] The preparation method is as follows: put 98.55kg of erythritol into a high-efficiency wet granulator model HLSG-100, and add 1kg of L-arabinose, 0.05kg of sucralose, and 0.4kg of edible essence into 2.9kg of water at 60°C to dissolve , After adding 2.9kg75% edible alcohol to be mixed with mixed solution. Pass the mixed solution through the compressed air watering can, so that the liquid is sprayed in the form of water mist, and the erythritol crystals are stirred while spraying. The stirring speed of the erythritol crystals is 40 rpm, so that the mixed solution is evenly attached to the erythritol Alcohol crystal surface; after the solution is sprayed, the material is then transferred to a material tray, put into a hot air oven for hot air dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com