one-way clutch

A technology of one-way clutches and outer wheels, applied in one-way clutches, clutches, solid diffusion coatings, etc., can solve problems such as poor meshing, poor responsiveness of rotating bodies, and high viscosity of lubricating oil, so as to achieve bending stress relaxation and reduction The effect of small idling torque and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

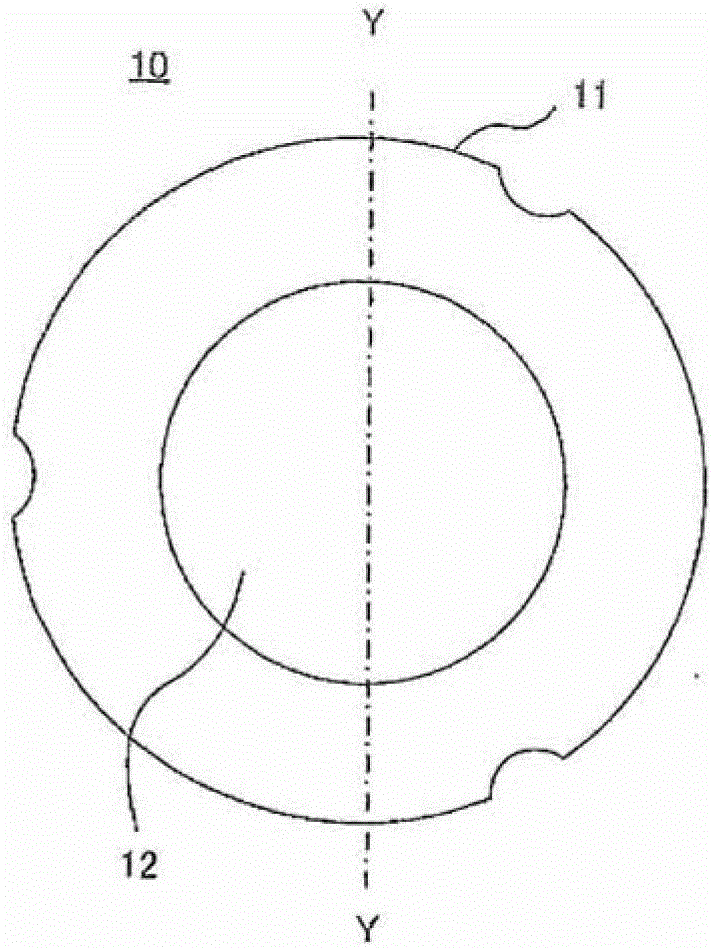

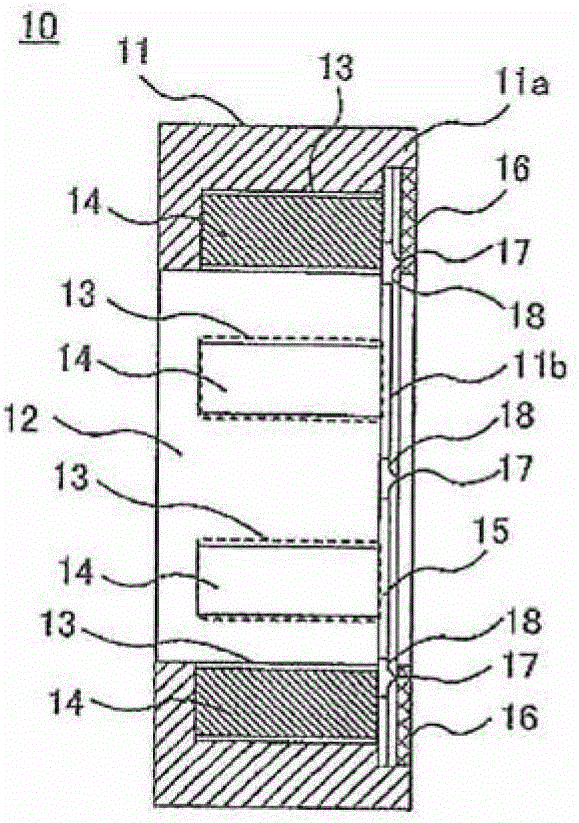

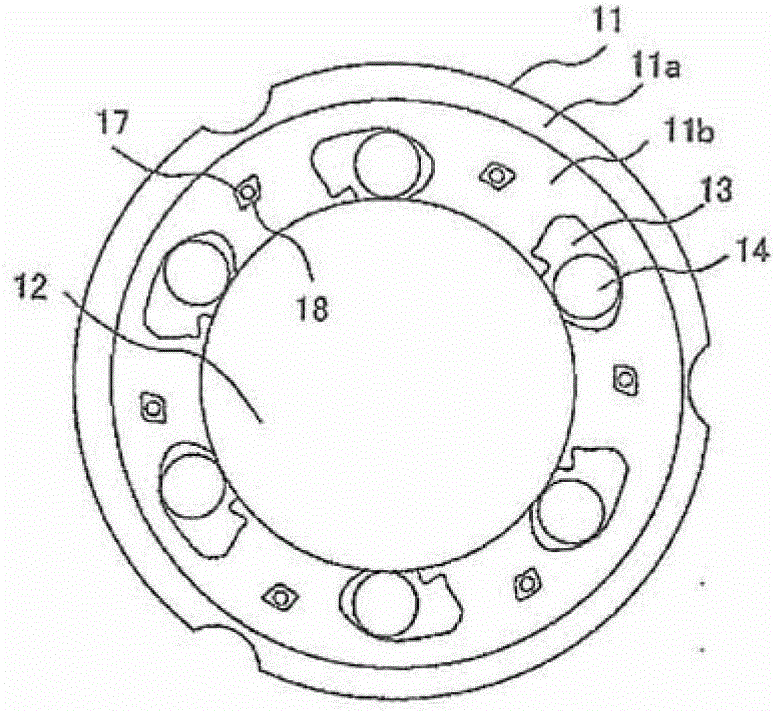

[0056] Embodiments of the present invention will be described below. Fig. 1 (a) and Fig. 1 (b) are structural diagrams showing an example of a one-way clutch 10 according to an embodiment of the present invention, Fig. 1 (a) is a front view, and Fig. 1 (b) is a view of Fig. 1 (a). Section view on Y-Y line.

[0057] 7 (a), FIG. 7 (b), and the conventional example shown in FIG. 7 (c), the embodiment of the present invention is provided in the recess 11b of the outer ring 11: a high seat 18 having a protruding portion 17. 7( a ), FIG. 7( b ), and FIG. 7( c ), the same reference numerals are attached to the same elements, and overlapping explanations are omitted.

[0058] As shown in FIG. 1( a ), the outer ring 11 of the one-way clutch 10 is formed in a cylindrical shape from a sintered member, and has a through hole 12 through which a shaft is inserted. Furthermore, as shown in FIG. 1( b ), a plurality of wedge-shaped spaces 13 are formed on the inner diameter surface of the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com