Nickel paste

A technology of nickel paste and powder, which is applied in the field of nickel paste, and can solve the problems of cracks, lack of film thickness and shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings. Furthermore, the drawings in the following embodiments have been appropriately simplified or distorted, and the dimensional ratios and shapes of various parts may not be accurately depicted.

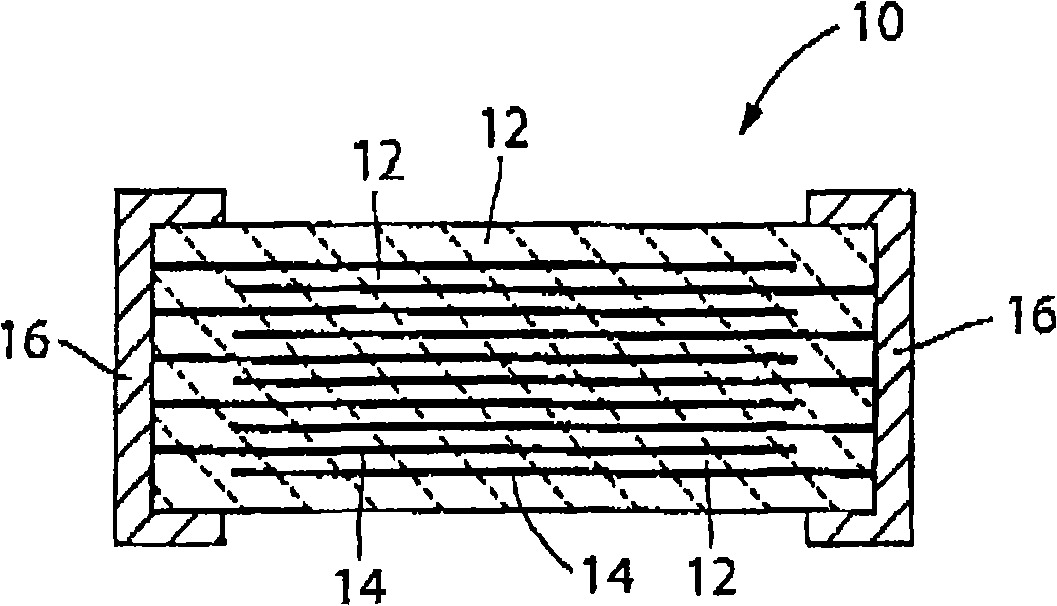

[0041] The following Tables 1-3 are the tables which put together the preparation state of the nickel paste of Examples 1-3 of this invention, and the evaluation result of stability, and Comparative Examples 1-3. The nickel paste, for example in the manufacture of the above-mentioned figure 1 In the case of the MLCC 10 shown, it is used to form the conductor layer 14 thereof. The dielectric layer 12 of the MLCC 10 is, for example, a layer made of barium titanate, and its thickness before firing is, for example, about 3 μm.

[0042] Table 1

[0043]

[0044] Table 2

[0045]

[0046] table 3

[0047]

[0048] In the above-mentioned Tables 1 to 3, "Ni powder"...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com