Method for producing physically modified starch

A technique of physically modifying starch and its manufacturing method, which is applied in medical preparations of non-active ingredients, pharmaceutical formulations, food science, etc., and can solve problems such as starch quality deterioration, and achieve the goal of suppressing viscosity changes and disintegration over time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0210] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited thereto. Unless otherwise specified, "part" means "mass part", and "%" means "mass %". In addition, the "*" mark in the text indicates that it is manufactured by Saneiyuan FFI Co., Ltd., and the "※" mark in the text indicates that it is a registered trademark of Saneiyuan FFI Co., Ltd.

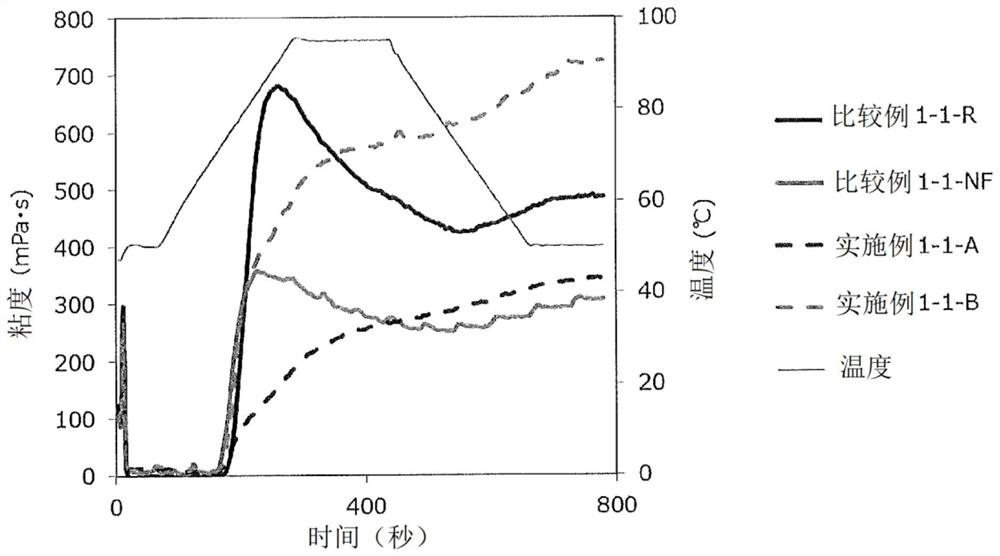

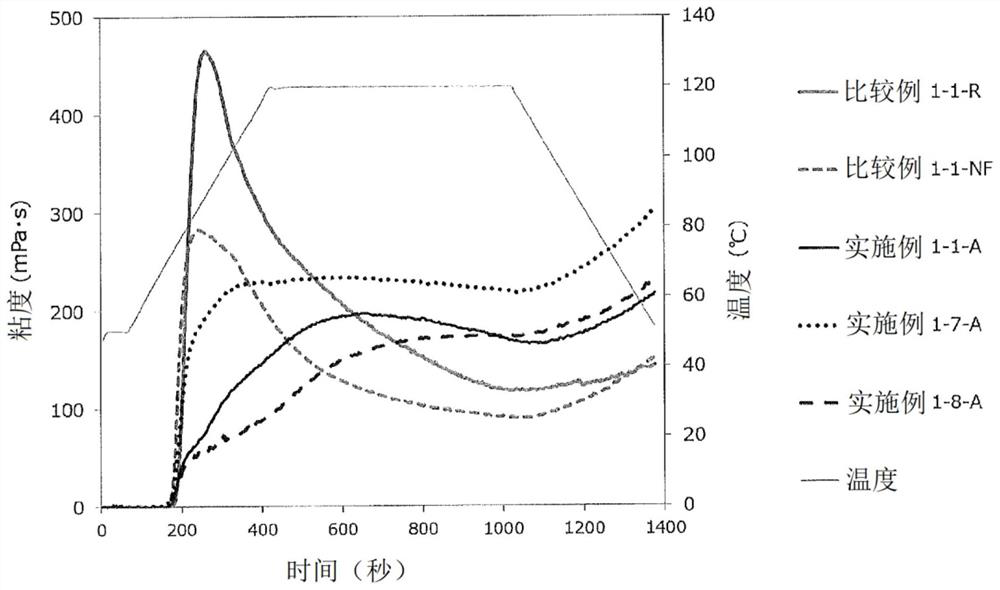

[0211] In the following, among the test examples, those with numbers ending in "R" are raw starches (comparative examples), and those with numbers ending in "NF" are those that do not contain dietary fiber derived from plants or dietary fiber derived from mushrooms. Modified starch (comparative example). In addition, the example which has the number with "A" and "B" at the end shows the method A or B of the addition method of the plant-derived dietary fiber or the mushroom-derived dietary fiber described in the following method. In addition, the example which...

manufacture example

[0326] [Manufacturing example: food containing modified starch]

[0327] (sweet and sour sauce)

[0328] Prepare the sweet and sour sauce of the formula in Table 9-1 according to the following method.

[0329]

[0330] (1) Add the modified starch of Example 1-1-A to water, and stir at 85 degreeC for 10 minutes.

[0331] (2) Add the remaining raw materials, stir for 5 minutes to dissolve them, fill them into heat-resistant pouches, and seal them.

[0332](3) Sterilize in a hot water bath at 85°C for 30 minutes.

[0333] [Table 9-1]

[0334] raw material parts by mass thick soy sauce 10 granulated sugar 15 salt 1 Brewed Vinegar (Acidity 10%) 6 sesame oil 0.5 The modified starch of embodiment 1-1-A 4 SANLIKE※Sauteed Onion 9Y55E(*) 0.1 SANLIKE※TasteBase A (modified)(*) 0.1 PEPPER SP-61524(OA)(*) 0.05 water 63.25 Total 100

[0335] (white sauce)

[0336] Prepare the white sauce of the formula o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com