A manual transmission oil

A technology of manual transmission and transmission oil, which is applied in the field of vehicle transmission system and manual transmission oil, which can solve the problems of shortened gear oil life and stickiness, so as to prevent the lack of oil on the tooth surface, improve the viscosity and temperature performance, and improve the oil film The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0037] According to the ratio of raw materials in Table 3 and according to the following method to prepare long-life, low-temperature energy-saving manual transmission oil, the specific raw material properties are shown in Table 2.

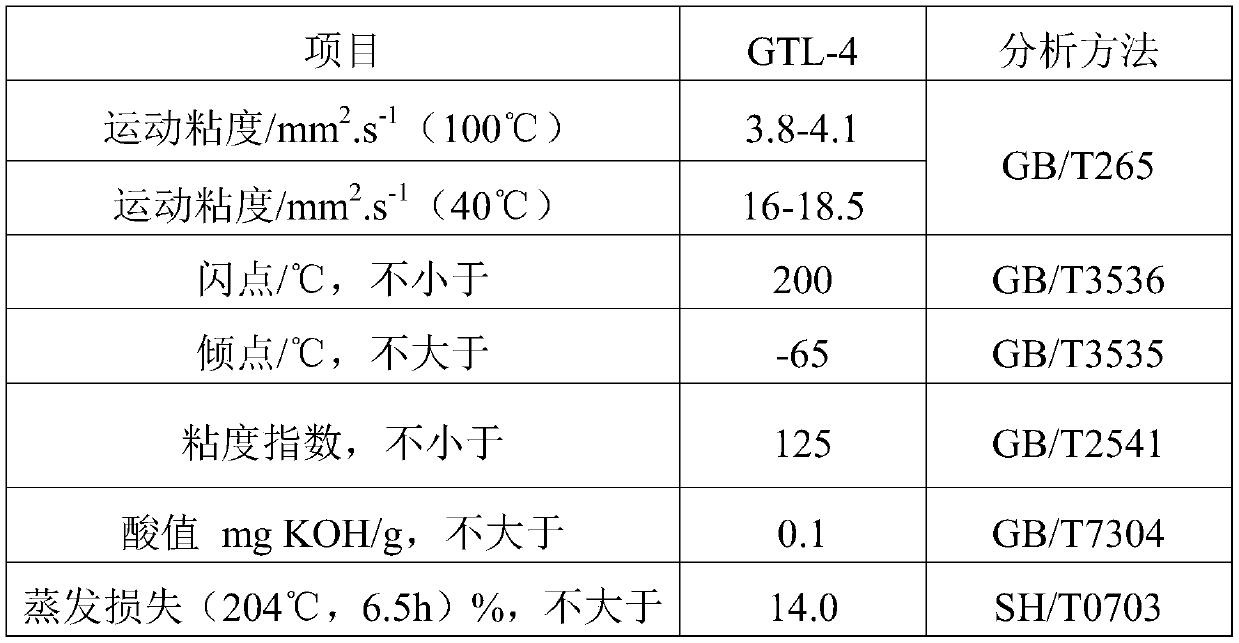

[0038] Table 2: Raw material properties in Examples 1-4

[0039] project Diester PAO-4 GTL Kinematic viscosity 100℃mm 2 .s -1

2.7 4.1 4.3 viscosity index 146 124 137 Flash point °C 204 221 231 Pour point °C -63 -64 -28

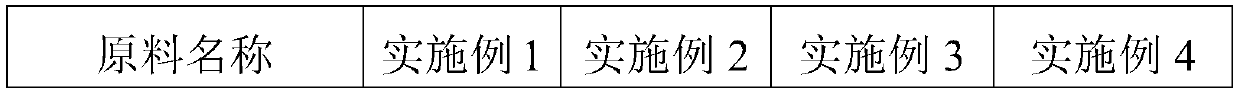

[0040] Table 3: Raw material proportioning unit in embodiment 1-4: kg

[0041]

[0042]

[0043] Add GTL-4 base oil and PAO-4 into the kettle, raise the temperature to 50°C, and stir for 0.5h; add high-viscosity polyester and polymethacrylate into the kettle, and stir for 0.5h; add the additive package into the kettle, and heat up To 65 ° C, fully mixed by stirring and static mixer, time 1.5h; the above process is carried out under the protection of 0.1MPa nitrogen, l...

Embodiment 5

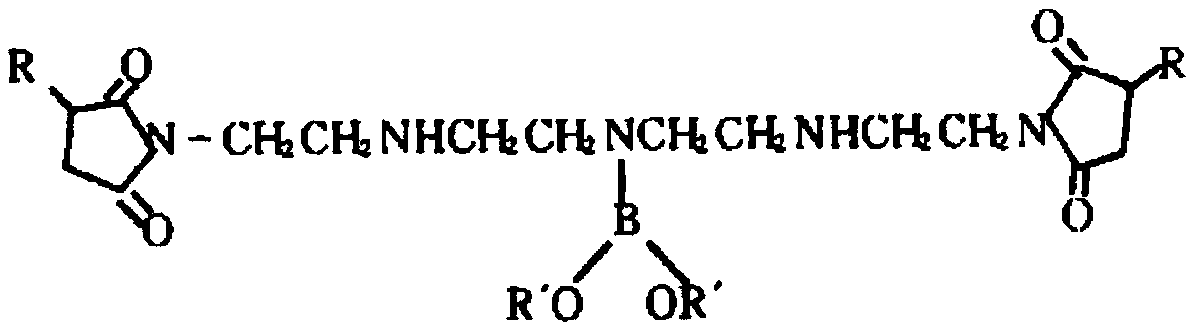

[0045] Preparation of compound additives for transmission oil: Add 3 parts by weight of calcium alkylbenzenesulfonate and 1 part by weight of sulfurized calcium alkylphenate to 60 parts by weight of alkyldibenzyltoluene and stir at 400 rpm for 10 minutes, then add 6 parts by weight Borated polyisobutylene succinimide was stirred at a speed of 400 rpm for 20 minutes to obtain a composite additive for transmission oil.

[0046] Long-life, low-temperature and energy-saving manual transmission oil raw materials (mass percentage): 6% of transmission oil compound additives, 35% of 13-docosanoic acid-13-docosyl ester, and 0.6% of polymethacrylate , polyalphaolefin 15%, di-n-octyl adipate 10%, organic molybdenum 0.08%, and the balance is GTL-4 base oil.

[0047] The organic molybdenum is obtained by uniformly stirring and mixing 50 wt % diethylhexyl molybdenum dithiophosphate and 50 wt % diisooctyl molybdenum dithiophosphate.

[0048] Preparation of long-life, low-temperature and energ...

Embodiment 6

[0050] Long-life, low-temperature energy-saving manual transmission oil was prepared according to the method of Example 5, the only difference being that the organic molybdenum was only diethylhexyl molybdenum dithiophosphate. Obtain the long-life, low-temperature energy-saving manual transmission oil of embodiment 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com