Silver dust and manufacturing method thereof

A silver powder and blender technology, applied in cable/conductor manufacturing, metal/alloy conductors, conductors, etc., can solve the problem of no consideration of related proposals, dispersibility, flake generation, etc., and achieve excellent uniformity and viscosity. Variation suppression and excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] 2492 g of silver chloride (manufactured by Sumitomo Metal Mining Co., Ltd.) was thrown into 36 L of 25% ammonia water kept at 36° C. in a warm bath at 38° C. while stirring to prepare a silver complex solution. The defoamer (manufactured by ADEKA CORPORATION, Adekanol LG-126) was diluted to 100 times by volume, and 24.4ml of the defoamer dilution was added to the above-mentioned silver complex solution, and the resulting silver complex solution was The warm bath was maintained at 36°C.

[0128] On the other hand, 1068 g of ascorbic acid (manufactured by Kanto Chemical Co., Ltd., reagent, 56.9% by mass relative to silver particles) as a reducing agent was dissolved in 13.56 L of pure water at 36° C. to prepare a reducing agent solution. Next, 159.5 g of polyvinyl alcohol as a water-soluble polymer (manufactured by Kuraray Co., Ltd., PVA205, 8.5% by mass relative to silver) was dissolved in 1 L of pure water at 36°C to prepare a solution, and the solution was Mix in redu...

Embodiment 2

[0145] Silver powder was produced in the same manner as in Example 1 above except that the usage-amount of polyvinyl alcohol as a water-soluble polymer was 65.7 g (Kuraray Co., Ltd. product, PVA205, 3.5 mass % with respect to silver particles).

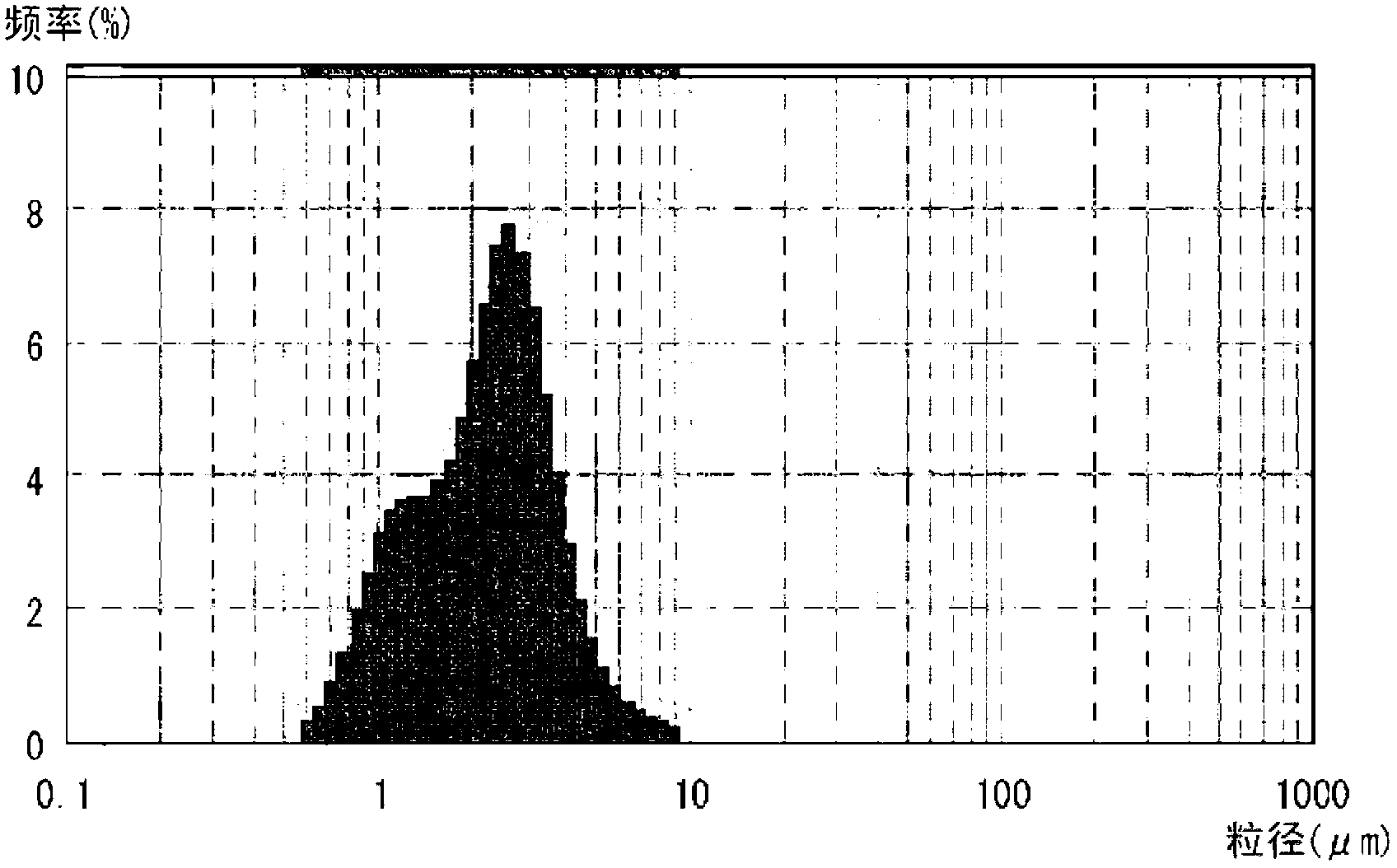

[0146] The obtained silver powder was evaluated in the same manner as in Example 1 above. As a result, the obtained particle size distribution was shown in Figure 4 , and the respective values are shown in Table 1 below.

[0147] In addition, using the obtained silver powder, a homogeneous kneaded product was produced with a self-revolving kneader (ARE-250 type manufactured by THINKY CORPORATION), and evaluated in the same manner as in Example 1. The obtained particle size distribution is shown in Figure 5 , and the obtained values are shown in Table 1 below.

[0148] Such as Figure 4 , Figure 5 As shown, the particle size distribution is in the region of 0.3μm~14.0μm, and the peak P 1 with shoulder P 2 The relationship i...

Embodiment 3

[0154] The amount of polyvinyl alcohol used as a water-soluble polymer was 262.8 g (Kuraray Co., Ltd., PVA205, 14.0% by mass relative to the silver particles), and the pulverization conditions were 5 L high-speed mixer (NIPPON COKE & ENGINEERING CO., LTD., FM5C) was stirred at a peripheral speed of 33 m / s for 30 minutes, and the silver powder was produced in the same manner as in the above-mentioned Example 1 except that it was decompressed and pulverized by a vacuum pump.

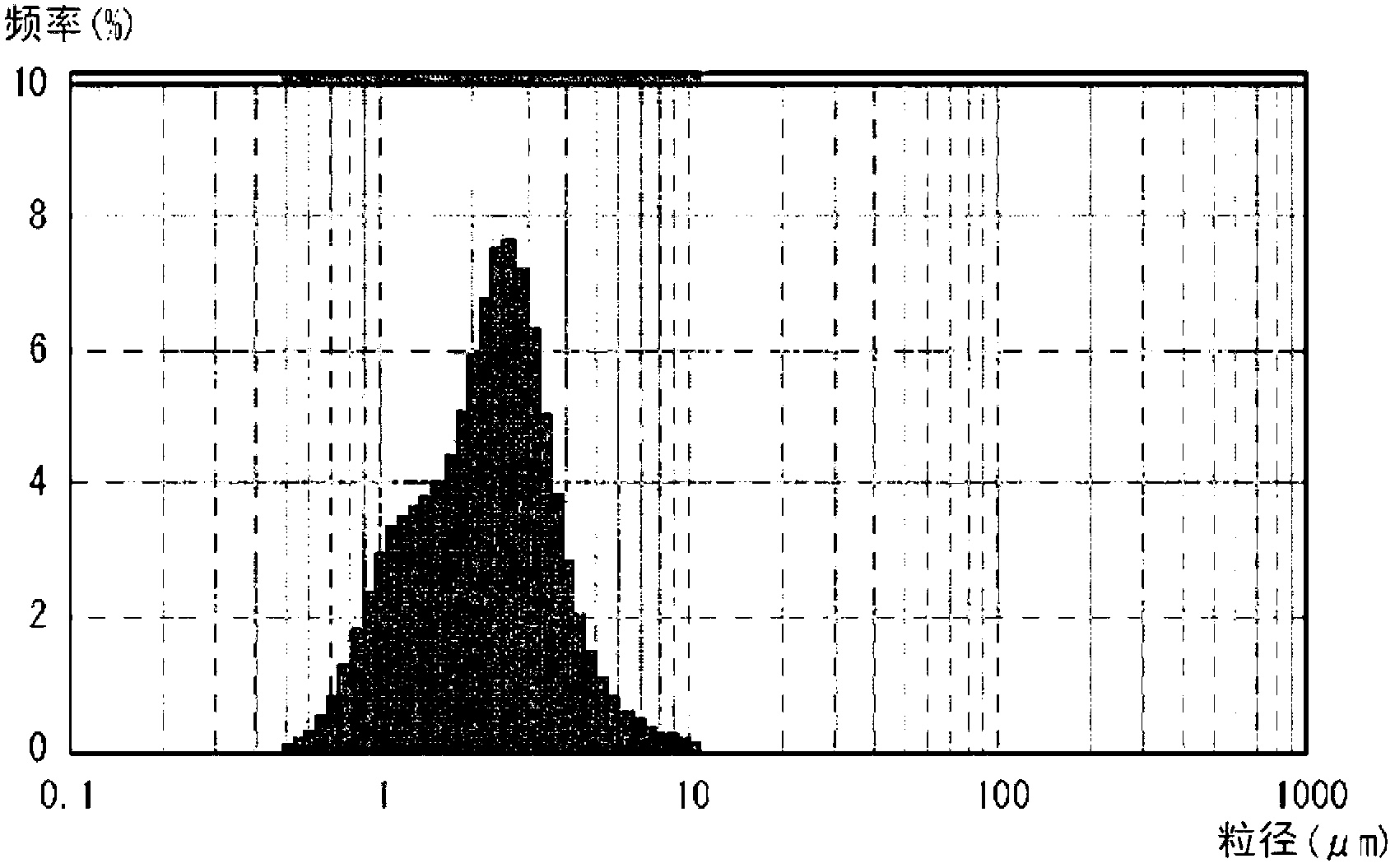

[0155] The obtained silver powder was evaluated in the same manner as in Example 1 above. As a result, the obtained particle size distribution was shown in Figure 6 , and the respective values are shown in Table 1 below.

[0156] In addition, using the obtained silver powder, a homogeneous kneaded product was produced with a self-revolving kneader (ARE-250 type manufactured by THINKY CORPORATION), and evaluated in the same manner as in Example 1. The obtained particle size distribution is shown in Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com