Method for manufacturing combined cam shaft

A manufacturing method and camshaft technology, applied in the field of mechanical processing, can solve the problems of complex mold processing, demanding process requirements, and high manufacturing costs, and achieve the effects of low overall cost, simple overall process, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

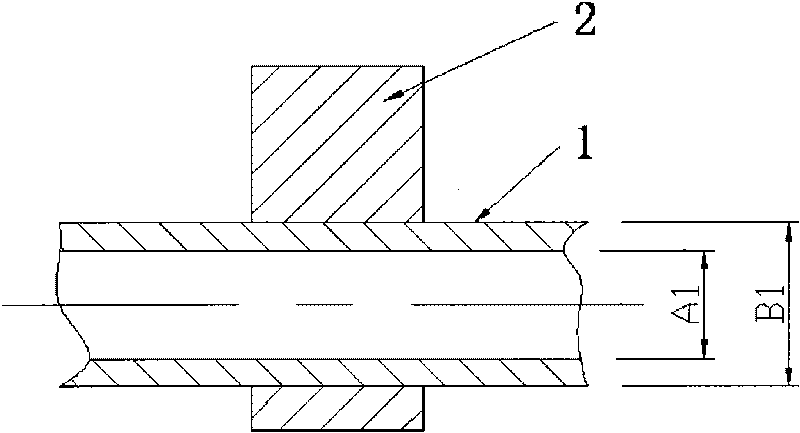

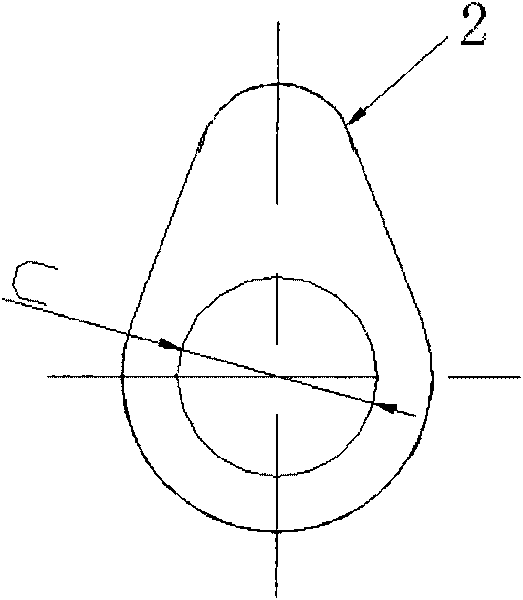

Embodiment 1

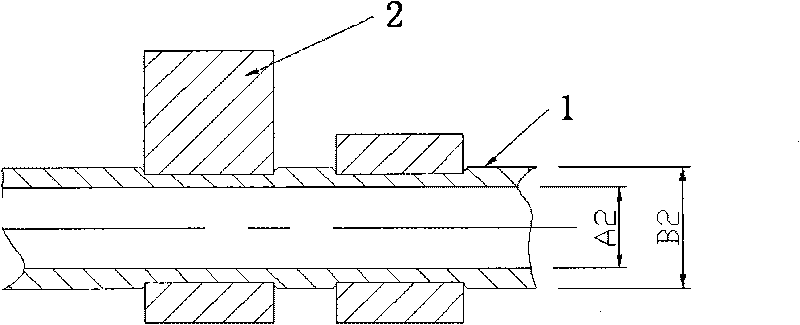

[0026] The mandrel is 20# steel pipe, inner diameter A1=16.00mm, outer diameter B1=22.02mm; the cam is an iron-based powder metallurgy part, its hardened layer thickness is greater than 1.50mm, HRC hardness is 55, inner diameter C=20.05mm; tapered slider Middle outer diameter D=16.20mm. The numerical control assembly machine is used to carry out interference tight fit and cold fit positioning according to the specified sequence, axial distance and phase angle requirements, and the cam 2 is fixed on the mandrel 1 through tight fit and cold fit, and then the tapered slider 3 is pulled by hydraulic pressure. Mandrel 1 is used to make the mandrel plastically deformed, so as to be closely combined with the elastically deformed cam 2. After expanding the tube, the inner diameter of the mandrel becomes A2=16.18mm, the outer diameter of the joint between the mandrel and the cam remains unchanged, and the outer diameter of the joint between the mandrel and the cam becomes B2=22.16mm. ...

Embodiment 2

[0028] The mandrel is 45# steel pipe, inner diameter A1=18.50mm, outer diameter B1=23.51mm; the cam is an iron-based powder metallurgy part, its hardened layer thickness is greater than 1.85mm, HRC hardness is 59, inner diameter C=23.55mm; tapered slider Middle outer diameter D=18.65mm. The numerical control assembly machine is used to carry out interference tight fit and cold fit positioning according to the specified sequence, axial distance and phase angle requirements, and the cam 2 is fixed on the mandrel 1 through tight fit and cold fit, and then the tapered slider 3 is pulled by hydraulic pressure. Mandrel 1 is used to make the mandrel plastically deformed, so as to be closely combined with the elastically deformed cam 2. After expanding the tube, the inner diameter of the mandrel becomes A2=18.62mm, the outer diameter of the joint between the mandrel and the cam does not change, but the outer diameter of the joint between the mandrel and the cam changes to B2=23.61mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com