Lead-free and halogen-free roll coating solder paste and preparation method thereof

A roll-coating and solder paste technology, which is applied in the field of lead-free and halogen-free roll-coating solder paste and its preparation, can solve the problems of poor oxidation resistance of solder paste, inability to keep wet for a long time, re-oxidation without protection, etc. Uniform and smooth hole welding process, excellent printing and forming effect, and good repeatable printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

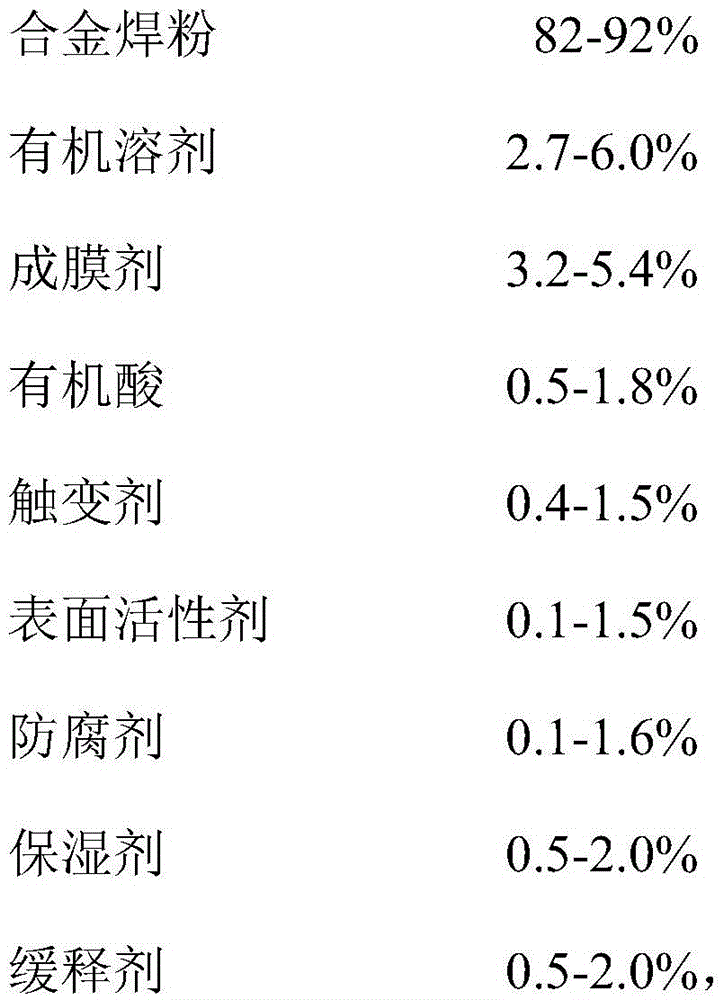

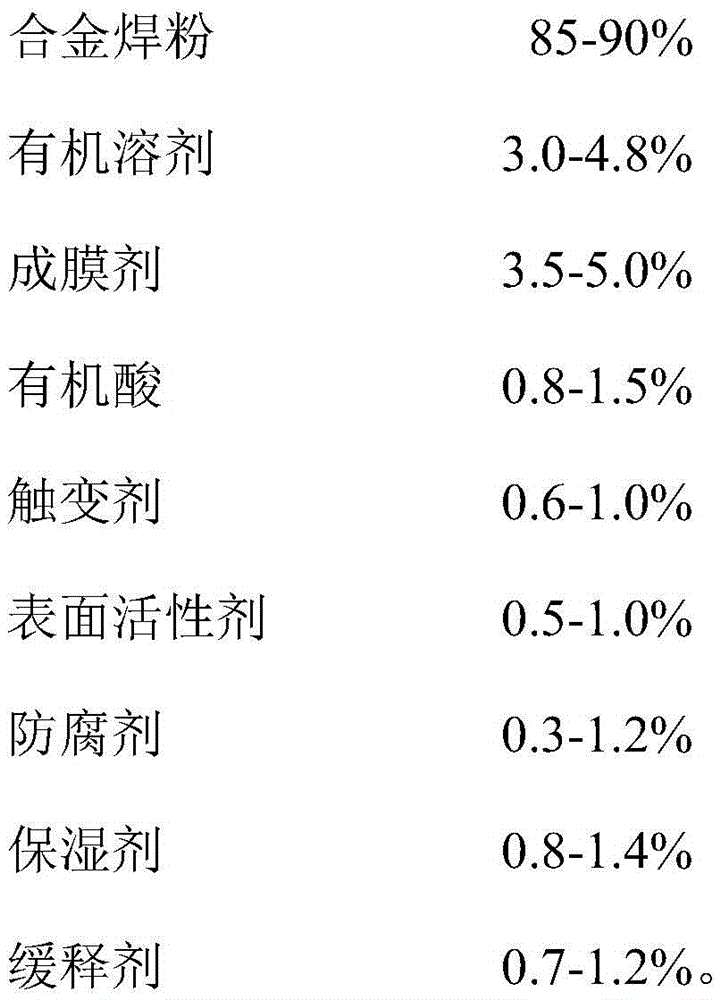

[0049] Example 1

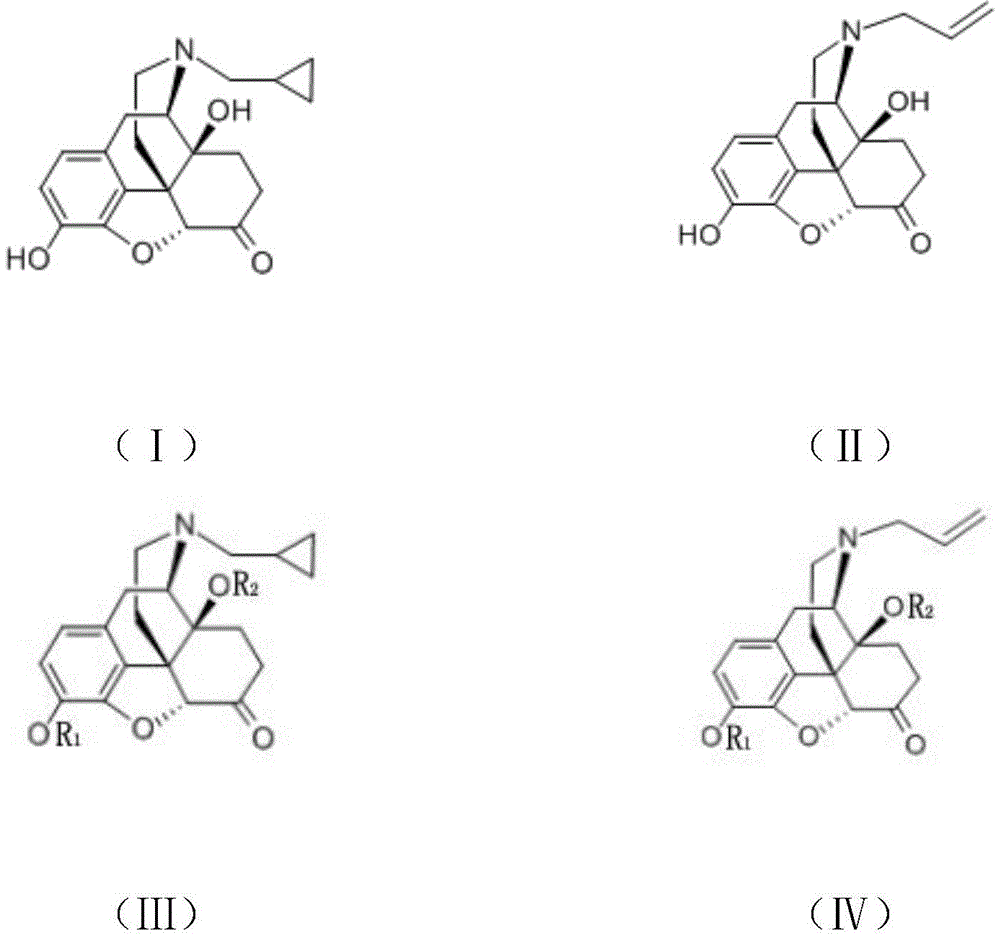

[0050] Add 4.5 g of ethylene glycol ethyl ether and 5 g of modified hydrogenated rosin to the mixing reaction kettle, and preheat it at 80°C for 5-15 minutes; raise the temperature to 150°C, heat and stir until it is completely dissolved to obtain a mixed solution. When the solution is cooled to 80°C, add 0.8 g of DL-malic acid, 0.6 g of hydrogenated castor oil and 0.8 g of hydroquinone and stir well, then let it cool to 52°C, and continue to add 0.5 g of octylphenol-10, 1 Gram propylene glycol, 1 gram of naltrexone, stir evenly, let stand, cool to room temperature to get the soldering paste, add the prepared soldering paste to the grinder, seal it after grinding and put it in a refrigerator at 0~10℃ for refrigeration After 12h, warm to room temperature, take 14g solder paste and 86g Sn 89.5 Sb 10 Ni 0.5 Stir evenly in a mixing barrel, prepare lead-free halogen-free roll-coating solder paste by vacuum degassing, and then divide it into cans or syringes accordin...

Example Embodiment

[0051] Example 2

[0052] Add 4 grams of ethylene glycol phenyl ether and 4 grams of fully hydrogenated rosin to the mixing reaction kettle, and preheat it at 90°C for 5-15 minutes; raise the temperature to 170°C, heat and stir until it is completely dissolved to obtain a mixed solution. When the solution is cooled to 80°C, add 0.7g of sebacic acid, 0.7g of polyamide sodium and 0.6g of ethylene glycol benzoxazole and stir well, then let it cool to 52°C, continue to add 1.0g of monoisooctyl phosphate and 0.5g Glycerol, 0.5 g of naloxone, stir evenly, let stand, cool to room temperature to obtain the soldering paste, add the prepared soldering paste to the grinder, seal it after grinding, and put it in a refrigerator at 0~10℃ After refrigerating for 12 hours, return to room temperature, take 12 grams of solder paste and 88 grams of Sn 90 Bi 8.5 Ag 1.5 Stir evenly in a mixing barrel, prepare lead-free halogen-free roll-coating solder paste by vacuum degassing, and then divide it int...

Example Embodiment

[0053] Example 3

[0054] Add 2.7 grams of ethylene glycol and 3.2 grams of fully hydrogenated rosin to the mixing reaction kettle, and preheat it at 80°C for 5-15 minutes; raise the temperature to 150°C, heat and stir until it is completely dissolved to prepare a mixed solution. When the mixed solution is cooled When it reaches 80℃, add 0.5g of citric acid, 0.4g of polyamide sodium and 0.1g of benzotriazole and stir well, then let it cool to 50℃, continue to add 0.1g of phenyl glycidyl ether and 0.5g of glycerol , 0.5g of naloxone, stir evenly, let it stand, cool to room temperature to get the soldering paste, add the prepared soldering paste to the grinder, seal it after grinding and put it in a refrigerator at 0~10℃ for 12h. , Warm to room temperature, take 8 grams of flux paste and 92 grams of Sn 90 Bi 10 Stir evenly in a mixing barrel, prepare lead-free halogen-free roll-coating solder paste by vacuum degassing, and then divide it into cans or syringes according to the requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com