Electron beam welding deformation control method of large variable-thickness component

A technology of electron beam welding and deformation control, applied in electron beam welding equipment, welding equipment, welding equipment, etc., can solve the problems of welding and welding deformation of non-variable-thickness cross-section components, reducing welding deformation and increasing the degree of restraint , to ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

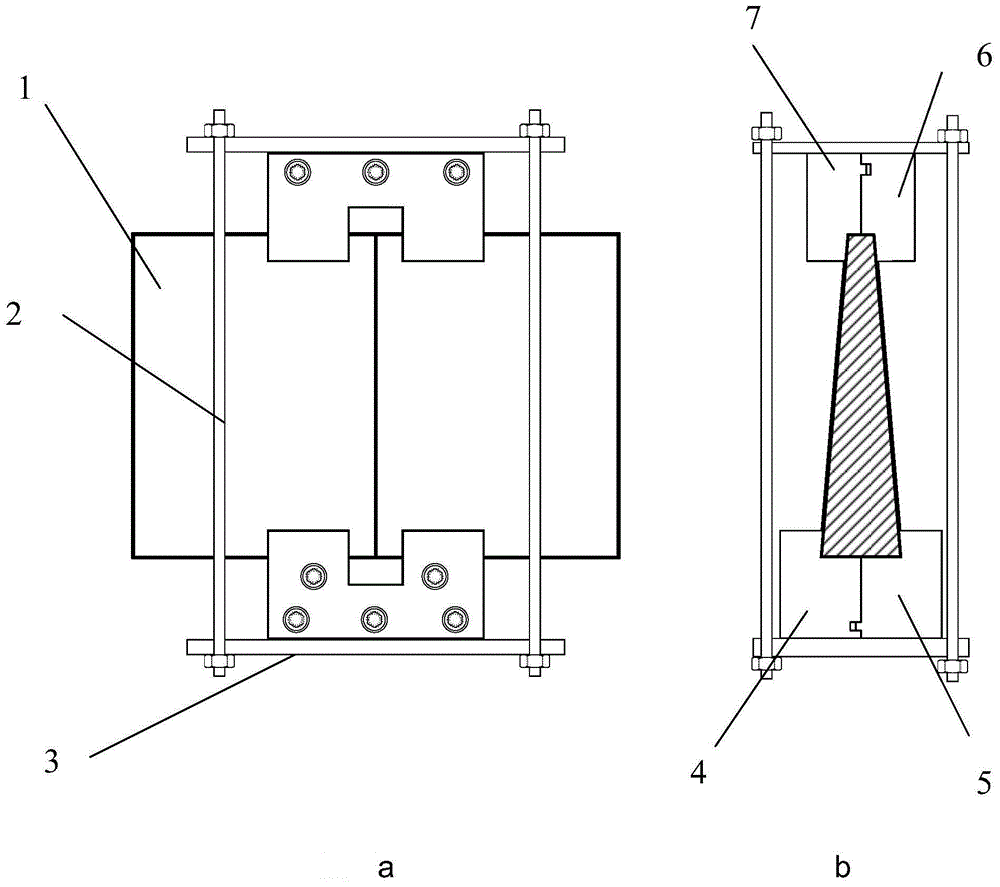

[0053] The material of the workpiece to be welded is titanium alloy, and the thickness of the weld seam is variable thickness, and the thickness varies from 20mm to 80mm.

[0054] (1) Clean the welding part of the workpiece to be welded before welding, remove the surface oil, and remove the oxide layer on the surface of the material by physical methods;

[0055] (2) Use the anti-deformation tooling to clamp the two workpieces 1 to be welded. The specific clamping method is the same as the above description. 30% of seam depth. The depths of the two through grooves of the tooling at the end with the smaller clamping thickness are both 30% of the depth of the weld seam of the workpiece 1 to be welded.

[0056] (3) Place the workpiece on the operating table of the vacuum electron beam welding machine and fix it with tooling;

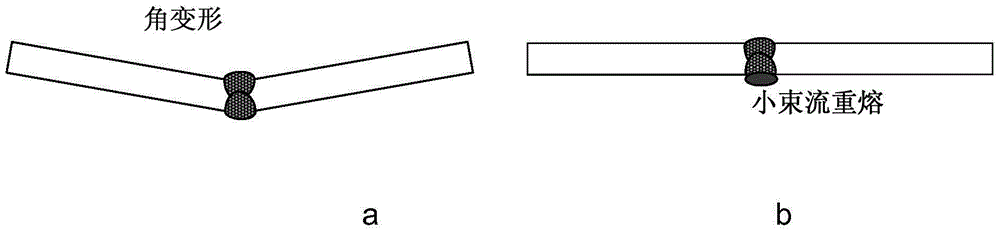

[0057] (4) The welding seam is pre-positioned with a small electron beam current. The positioning method is double-sided positioning of the weld seam. The...

Embodiment 2

[0062] The material of the workpiece to be welded is titanium alloy, and the thickness of the weld seam is variable thickness, and the thickness varies from 10mm to 50mm.

[0063] (1) Clean the welding part of the workpiece to be welded before welding, remove the surface oil, and remove the oxide layer on the surface of the material by physical methods;

[0064] (2) Use the anti-deformation tooling to clamp the two workpieces 1 to be welded. The specific clamping method is the same as the above description, and the depth of the two through grooves of the tooling at the end with the thicker clamping thickness is 10% of the depth of the weld. %. The depth of the two through grooves of the tooling at the end of the clamping thickness is 10% of the depth of the weld.

[0065] (3) Place the workpiece on the operating table of the vacuum electron beam welding machine and fix it with tooling;

[0066] (4) The welding seam is pre-positioned with a small electron beam current. The po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com