Large-sized iron casting fracture arc cold-welding repair method

A repair method and technology for iron castings, applied in arc welding equipment, welding medium, welding equipment, etc., can solve the problems of unstable preheating temperature, imbalance, welding failure, etc., and achieve good welding effect and simple process

Inactive Publication Date: 2009-02-11

JIANGXI COPPER CORP

View PDF0 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this welding method is sometimes limited by environmental conditions and cannot be carried out. For example, in cold seasons or alpine regions, without special heating and insulation facilities, the preheating temperature is unstable and uneven, and it cannot be done after welding. Slow cooling, resulting in white structure of welded joints, cracks in weld seam and heat-affected zone, and the entire weld seam will be peeled off from the base metal, resulting in welding failure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

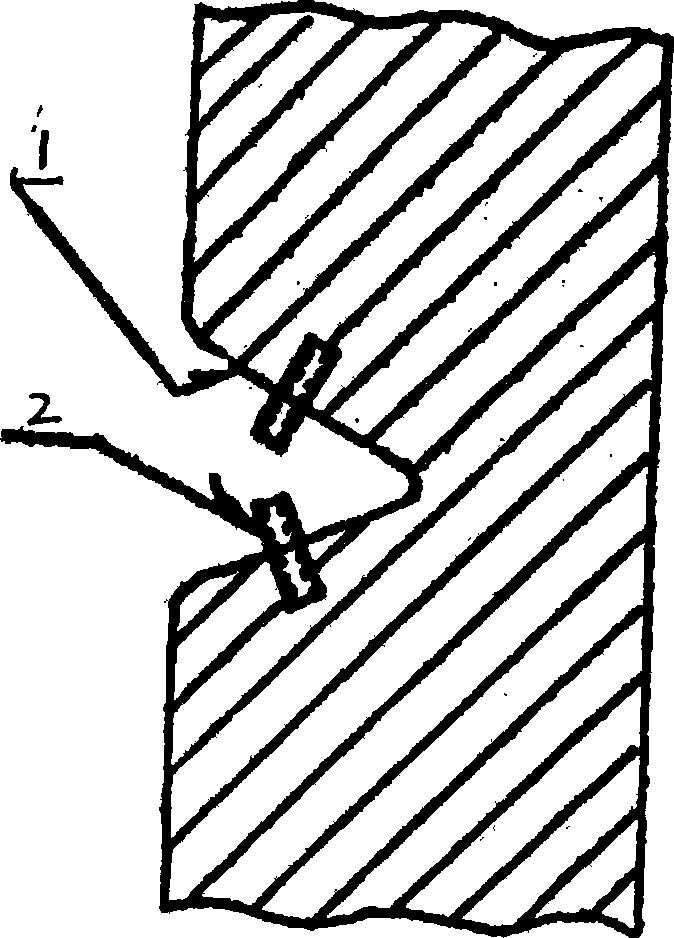

[0012] control figure 1 It can be seen that before the welding of the present invention, one layer of metal must be planed along the crack direction at the fracture section to form a V-shaped groove 1, and then each groove both sides are drilled and tapped, and the steel screw 2 is screwed in.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a cold welding fracture recovery method for a large-scale cast iron piece. Non cast iron welding material is selected, a layer of metal is scraped off on the fracture surface along the crack direction, so as to form a V-shaped groove; steel screws are screwed in the two sides of the groove, and a direct current welder is used for multi-layer welding. The technique of the invention carries out welding repair to the fracture of the large-scale cast iron piece under the condition of not being influenced by climate, the technique is simple, and the welding effect is good.

Description

Technical field: [0001] The invention relates to a method for welding and repairing fractures of large iron castings, belonging to the technical field of metal material welding. Background technique: [0002] Cast iron is a difficult-to-weld material. Although there are many welding methods for iron castings, semi-heat welding is usually used for repairing the fracture of large iron castings: that is, preheating the parts to be welded to 400°C before welding. Then carry out welding, and then carry out heat preservation and slow cooling after welding. However, this welding method is sometimes limited by environmental conditions and cannot be carried out. For example, in cold seasons or alpine regions, without special heating and insulation facilities, the preheating temperature is unstable and uneven, and it cannot be done after welding. Slow cooling will cause white structure in the welded joint, cracks in the weld seam and heat-affected zone, and the entire weld seam will ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K9/04B23K35/30B23K9/235B23K33/00

Inventor 黄初皓

Owner JIANGXI COPPER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com