Anti-splashing laser soldering paste and preparation method thereof

A laser welding and anti-spatter technology, used in welding equipment, welding media, manufacturing tools, etc., can solve problems such as poor wettability, spatter, tin beads, etc., achieve high adhesion, reduce substrate oxidation, and reduce tin The effect of beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

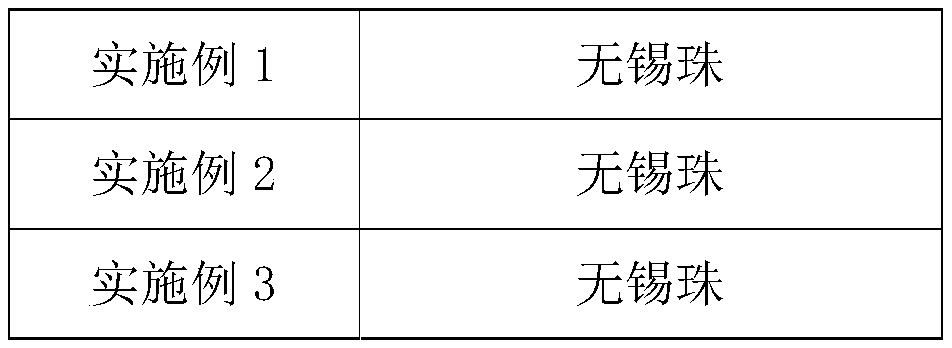

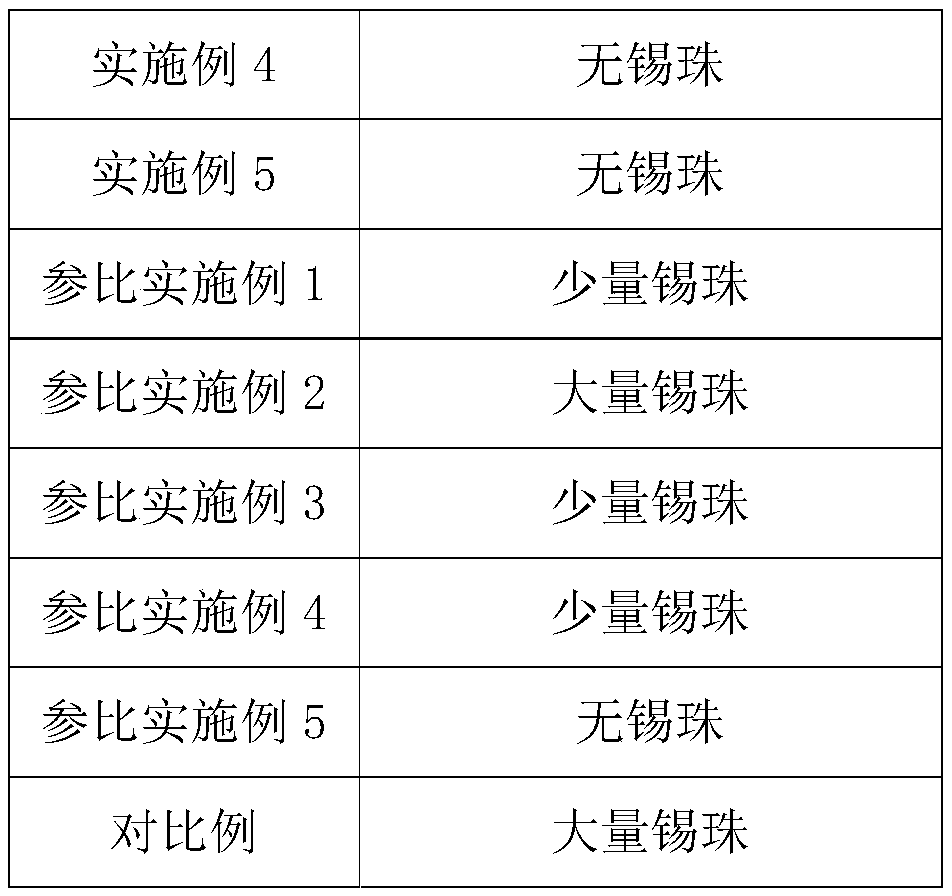

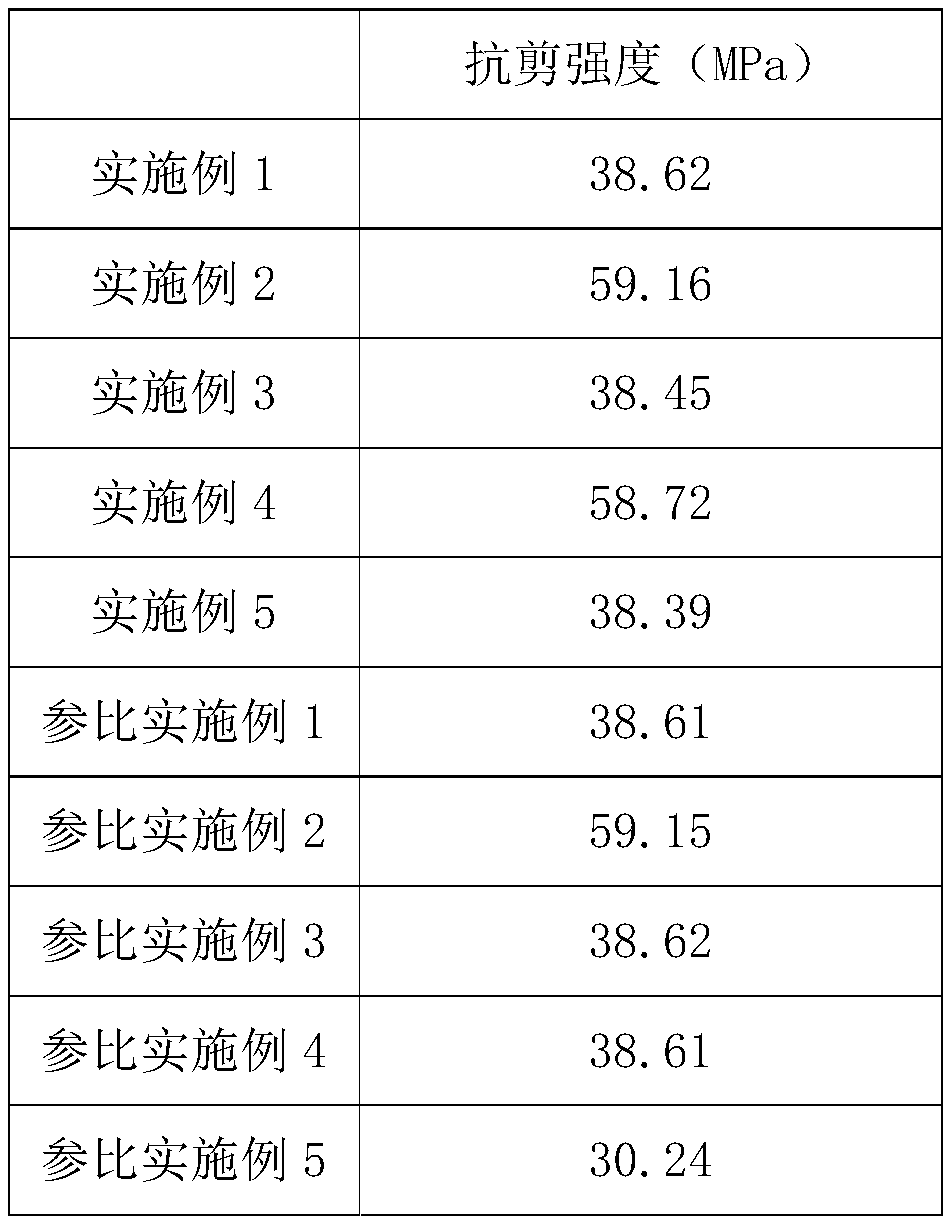

Examples

Embodiment 1

[0034] The anti-splash laser solder paste is composed of the following raw materials in weight percentage: alloy powder 88.7%, flux 11.3%;

[0035] Among them, the alloy powder is Sn96.5Ag3.0Cu0.5 with a melting point of 138°C prepared according to the United States Joint Industry Standard J-STD-005;

[0036] The flux is composed of the following components: KR-610 rosin 31.5g, KE-604 rosin 13.5g, polyamide 3g, hydrogenated castor oil 6g, suberic acid 3g, malic acid 4g, 3-propanolamine 5g, high boiling point additive 4g, 1.5g of compound X, 24.5g of diethylene glycol monooctyl ether, and 4g of glycerol.

[0037] Wherein, the high boiling point additive is composed of the following components in weight percentage: 25% of ethylene glycol diacetate, 25% of dimethylacetamide, and 50% of 2-phenoxyethanol.

[0038] The preparation steps of compound X are:

[0039] Add 1,3-dichloropropane, ethylimidazole, and toluene with a ratio of 0.5mol:1mol:250mL into the reaction flask, conden...

Embodiment 2

[0046] The anti-splash laser solder paste is composed of the following raw materials in weight percentage: alloy powder 89.5%, flux 10.5%;

[0047] Among them, the alloy powder is Sn42Bi58 prepared according to the United States Joint Industry Standard J-STD-005 with a melting point of 217°C;

[0048] The flux is composed of the following components: KR-610 rosin 29.4g, KE-604 rosin 12.6g, polyamide wax 3g, hydrogenated castor oil 6g, glutaric acid 4g, succinic acid 2g, 3-propanolamine 5g, high boiling point Additive 4g, compound X 2g, diethylene glycol monooctyl ether 28g, glycerol 4g.

[0049] Wherein, the high boiling point additive is composed of the following components in weight percentage: 25% of ethylene glycol diacetate, 25% of dimethylacetamide, and 50% of 2-phenoxyethanol.

[0050] The preparation steps of Compound X are the same as in Example 1.

[0051] The preparation method of the present embodiment comprises the following steps:

[0052] S1. Weigh each compo...

Embodiment 3

[0057] The anti-splash laser solder paste is composed of the following raw materials in weight percentage: alloy powder 88%, flux 12%;

[0058] Among them, the alloy powder is Sn96.5Ag3.0Cu0.5 with a melting point of 138°C prepared according to the United States Joint Industry Standard J-STD-005;

[0059] The flux consists of the following components: KR-610 rosin 34.3g, KE-604 rosin 14.7g, polyamide 3g, glyceryl tris(12-acetyl ricinoleate) 5g, adipic acid 4g, glutaric acid 3g , acrylamide 5g, high boiling point additive 4g, compound X1g, diethylene glycol monooctyl ether 22g, tetraethylene glycol dibutyl ether 4g.

[0060] Wherein, the high boiling point additive is composed of the following components in weight percentage: 25% of ethylene glycol diacetate, 35% of dimethylacetamide, and 40% of 2-phenoxyethanol.

[0061] The preparation steps of Compound X are the same as in Example 1.

[0062] The preparation method of the present embodiment comprises the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com