Aluminum welding tin paste and preparation method thereof

A technology of solder paste and tin powder, applied in the direction of welding equipment, welding medium, manufacturing tools, etc., can solve the problems of unsatisfactory solder, unusable soldering or dip soldering, etc., and achieve good soldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

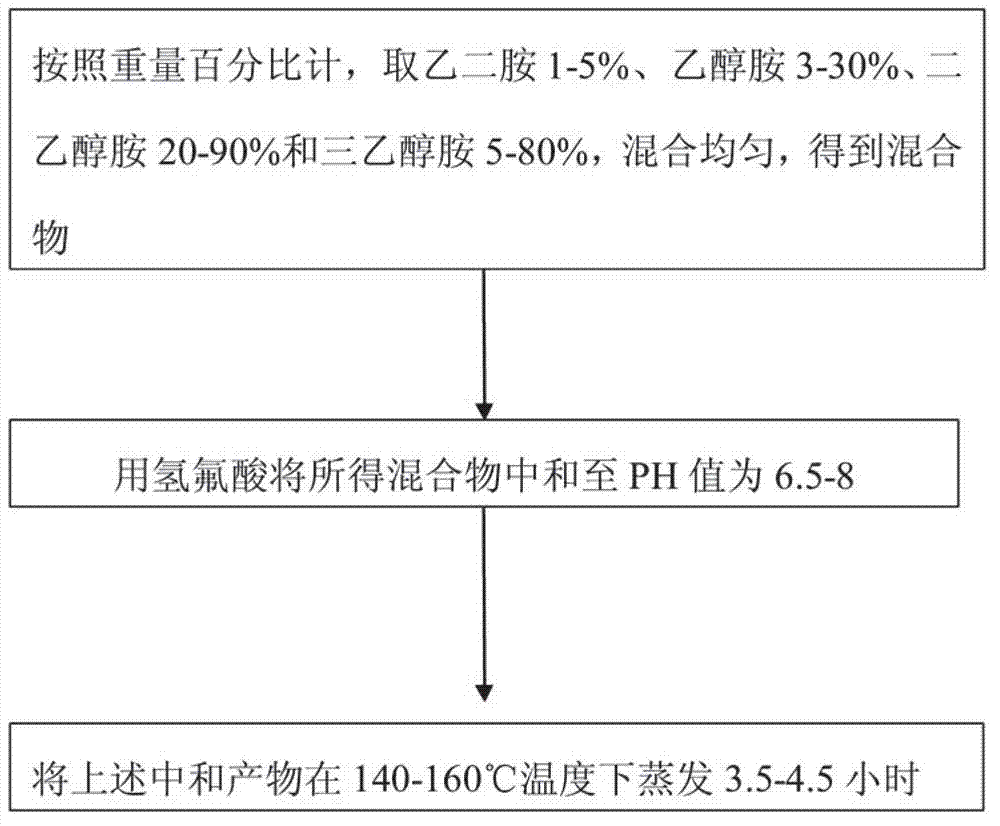

[0028] The preparation method of the hydroxylamine fluoride comprises the following steps:

[0029] 1) In terms of weight percentage, take 1-5% of ethylenediamine, 3-30% of ethanolamine, 20-90% of diethanolamine and 5-80% of triethanolamine, and mix them uniformly to obtain a mixture;

[0030] 2) Neutralize the resulting mixture with hydrofluoric acid to a pH value of 6.5-8;

[0031] 3) Evaporate the above neutralized product at a temperature of 140-160°C for 3.5-4.5 hours.

[0032] The metal active salt is one or more of tin fluoride, stannous fluoride, stannous fluoroborate, stannous chloride, zinc fluoride, zinc fluoroborate, zinc chloride and bismuth chloride combination.

[0033] The activator is one or a combination of diethylamine hydrochloride, triethylamine hydrochloride, lithium fluoride, sodium fluoride, magnesium fluoride and aluminum fluoride.

[0034] The corrosion inhibitor is benzotriazole and / or piperazine.

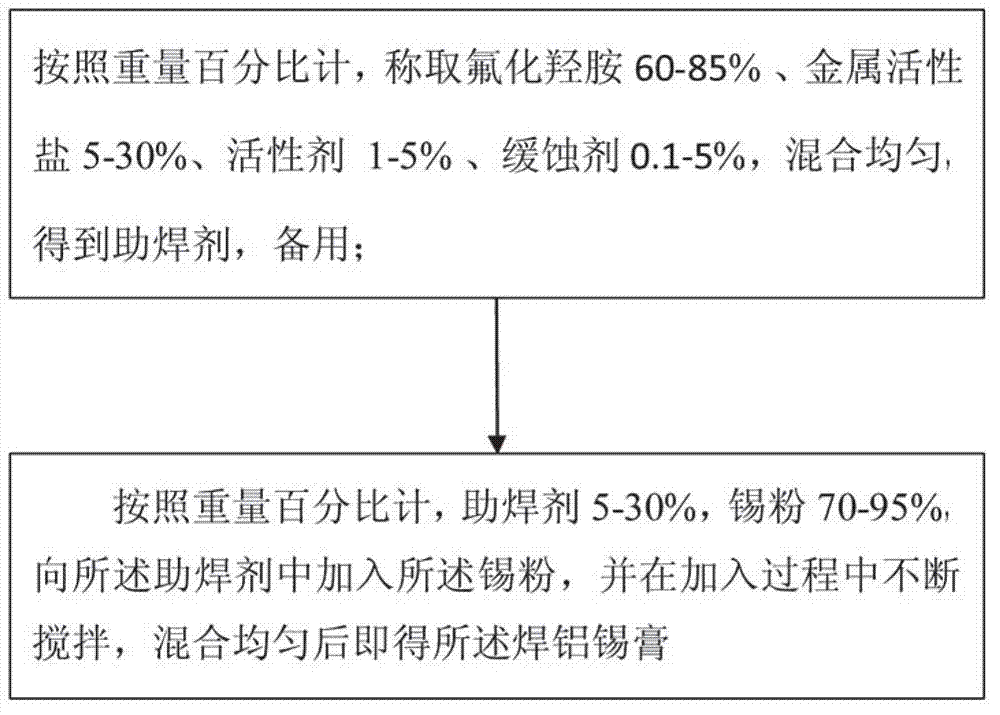

[0035] A method for preparing aluminum solder p...

Embodiment 1

[0043] The preparation method of hydroxylamine fluoride, it may further comprise the steps:

[0044] 1) According to weight percentage, take ethylenediamine 1%, ethanolamine 30%, diethanolamine 64% and triethanolamine 5%, mix and stir evenly to obtain a mixture;

[0045] 2) neutralize the resulting mixture with hydrofluoric acid to a pH value of 6.5;

[0046] 3) Evaporate the above-mentioned neutralized product at 140°C for 4.5 hours to remove the moisture and prevent subsequent welding spatter.

Embodiment 2

[0048]The preparation method of hydroxylamine fluoride, it may further comprise the steps:

[0049] 1) According to weight percentage, take 5% ethylenediamine, 3% ethanolamine, 84% diethanolamine and 8% triethanolamine, mix and stir evenly to obtain a mixture;

[0050] 2) Neutralize the resulting mixture to a pH value of 7 with hydrofluoric acid;

[0051] 3) Evaporate the above-mentioned neutralized product at 160°C for 3.5 hours to remove the moisture and prevent subsequent welding spatter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com