Water cleaning type tin soldering paste soldering flux

A flux and solder paste technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems that the solubility affects the performance of electronic components, the flux cannot be dissolved by water, and is not easy for users to accept, etc. , to achieve effective welding activity, good welding effect and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

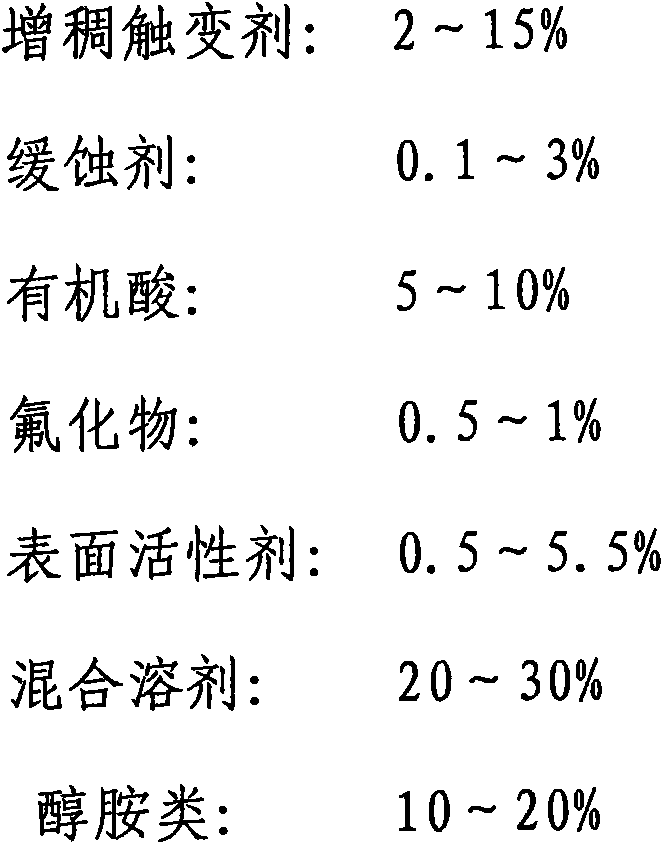

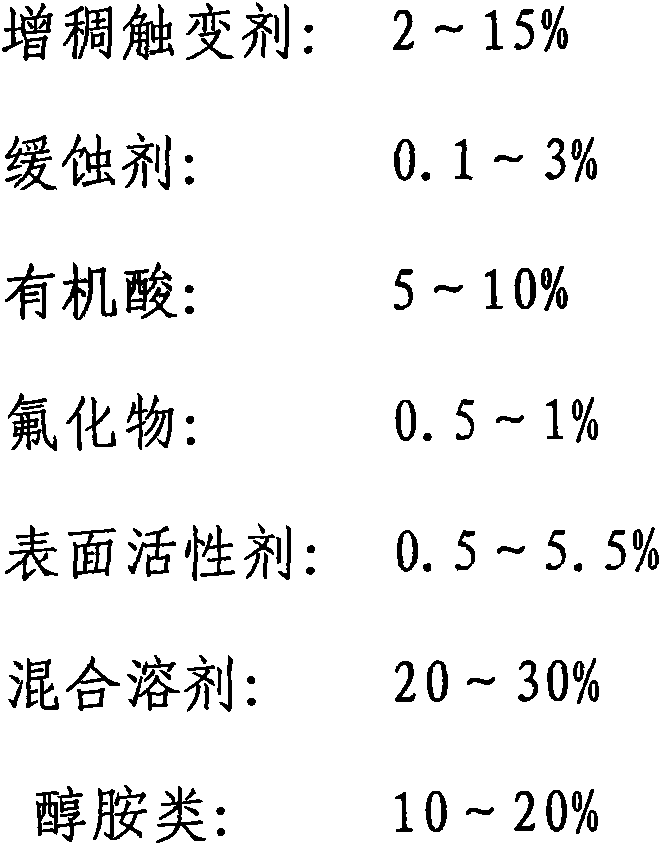

Method used

Image

Examples

Embodiment 1

[0027] Soldering flux: Prepare the following flux raw materials by weight percentage: 40% hydrogenated rosin, 18% triethanolamine, 24.5% diethylene glycol monobutyl ether, 1% antioxidant BHT, 1% benzotriazole, succinic acid 2%, ammonium oxalate 2%, oxalic acid 0.3%, polymeric acid 3.2%, ammonium succinate 3%, ammonium bifluoride 0.5%, behenamide 4.5%. Heat the rosin and triethanolamine evenly to 160°C. After they are completely melted, add the rest of the materials and stir to dissolve all the materials. The appearance is a uniform and clear liquid. Filter after heating, filter the heated and melted flux through a 100-mesh filter, pour it into a high-temperature bag to cool, and put it away after cooling to room temperature. It can be used to configure tin-silver-copper alloy solder paste.

Embodiment 2

[0029] Soldering flux: Prepare the following flux raw materials by weight percentage: 30% hydrogenated rosin, 10% disproportionated rosin, 10% triethanolamine, 8% diethanolamine, 24.5% diethylene glycol monobutyl ether, anti-aging agent BHT1%, benzene Triazole 1%, succinic acid 2%, ammonium oxalate 2%, oxalic acid 0.3%, polyacid 3.2%, ammonium succinate 3%, ammonium bifluoride 0.5%, behenamide 4.5% . Heat the rosin and triethanolamine evenly to 160°C. After they are completely melted, add the rest of the materials and stir to dissolve all the materials. The appearance is a uniform and clear liquid. Filter after heating, filter the heated and melted flux through a 100-mesh filter and pour it into a high-temperature bag to cool. After cooling to room temperature, it becomes the required flux, which is suitable for tin-silver-copper alloy solder.

Embodiment 3

[0031] Soldering flux: prepare the following flux raw materials by weight percentage: 40% hydrogenated rosin, 8% ethanolamine, 10% diethanolamine, 26.5% diethylene glycol monohexyl ether, 1% antioxidant BHT, 1% succinic acid, ethyl alcohol Ammonium diacid salt 1%, oxalic acid 0.3%, polymeric acid 2.2%, ammonium succinate 5%, ammonium bifluoride 0.5%, polyamide wax thickener (Disparon 6500) 4.5%. Heat the rosin and triethanolamine evenly to 160°C. After they are completely melted, add the rest of the materials and stir to dissolve all the materials. The appearance is a uniform and clear liquid. Filter after heating, filter the heated and melted flux through a 100-mesh filter and pour it into a high-temperature bag to cool. After cooling to room temperature, it becomes the required flux, which is suitable for tin-copper alloy solder.

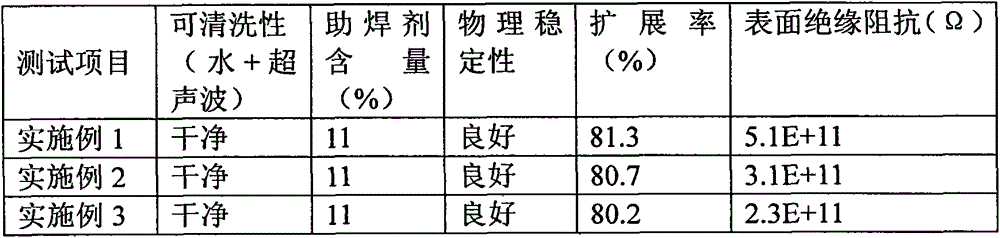

[0032] The above flux uses 11% SAC305 alloy 3# tin powder to configure solder paste, and the effect after cleaning with water after soldering is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com