Stacked via-stud with improved reliability in copper metallurgy

a copper metallurgy and via-stud technology, applied in the direction of semiconductor/solid-state device details, thin material processing, semiconductor devices, etc., can solve the problems of increasing crack propensity, increasing crack generation, and increasing the proneness of stacked via-studs to cracks, so as to facilitate redundant paths and increase the flexibility of stacked via-studs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

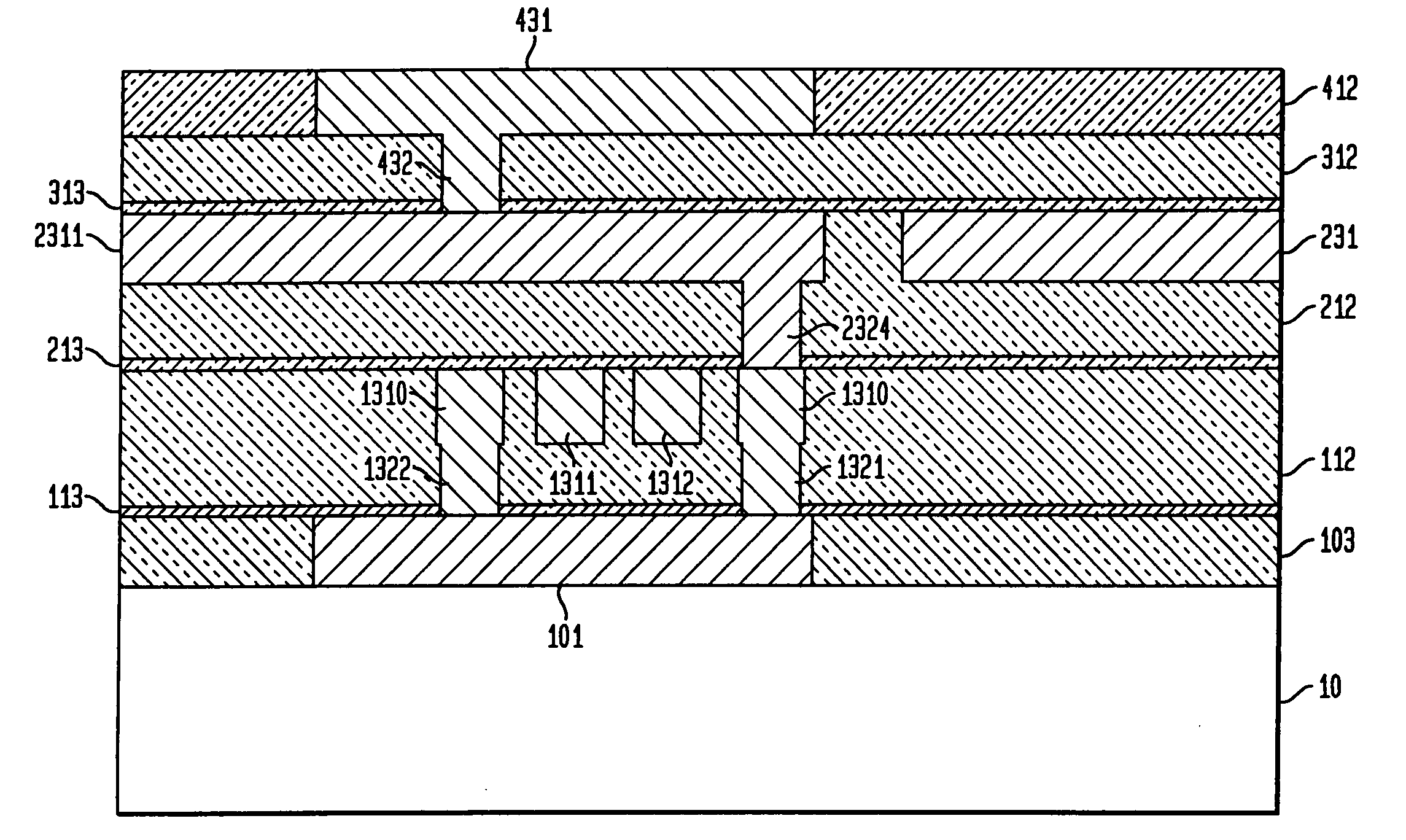

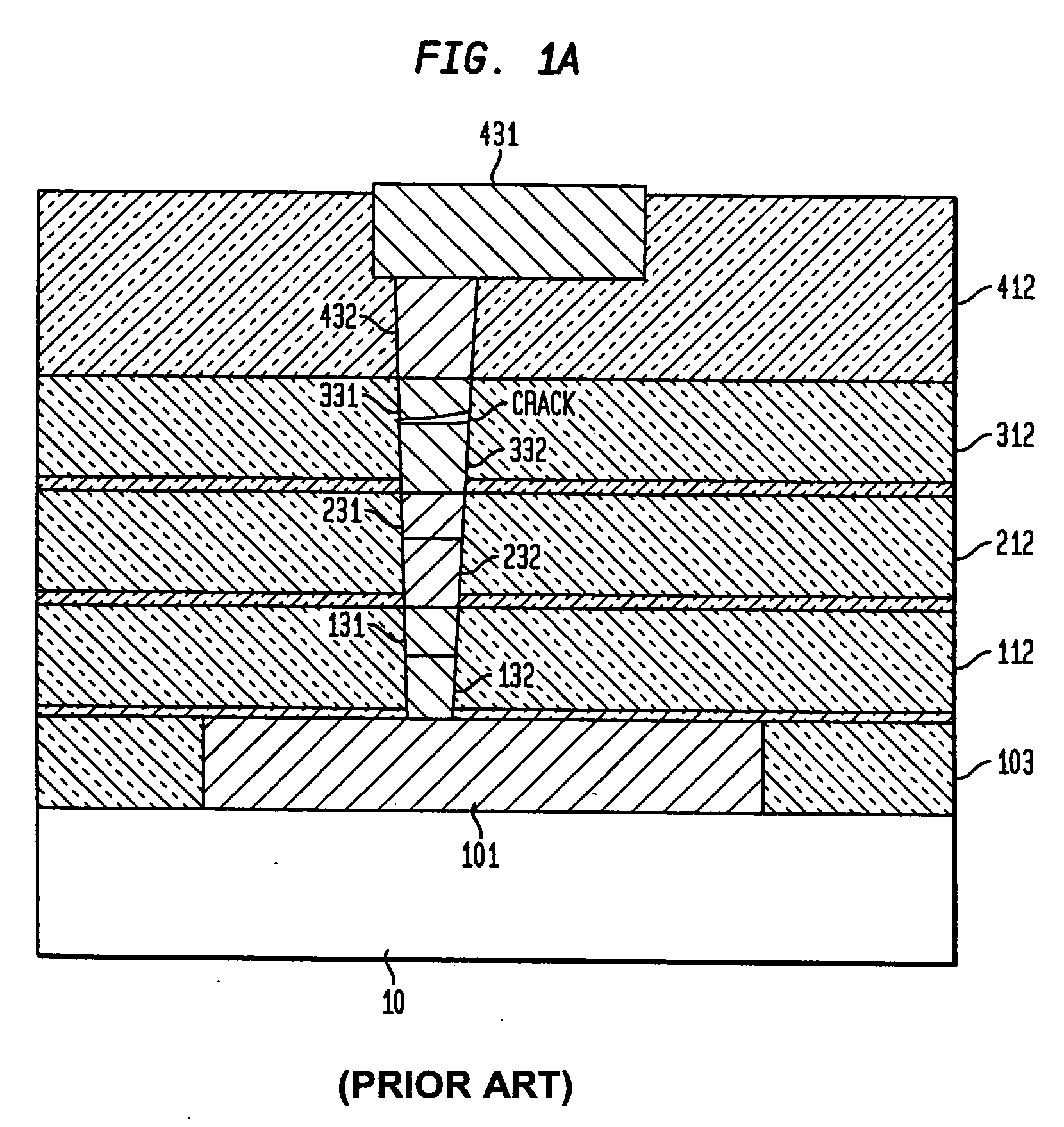

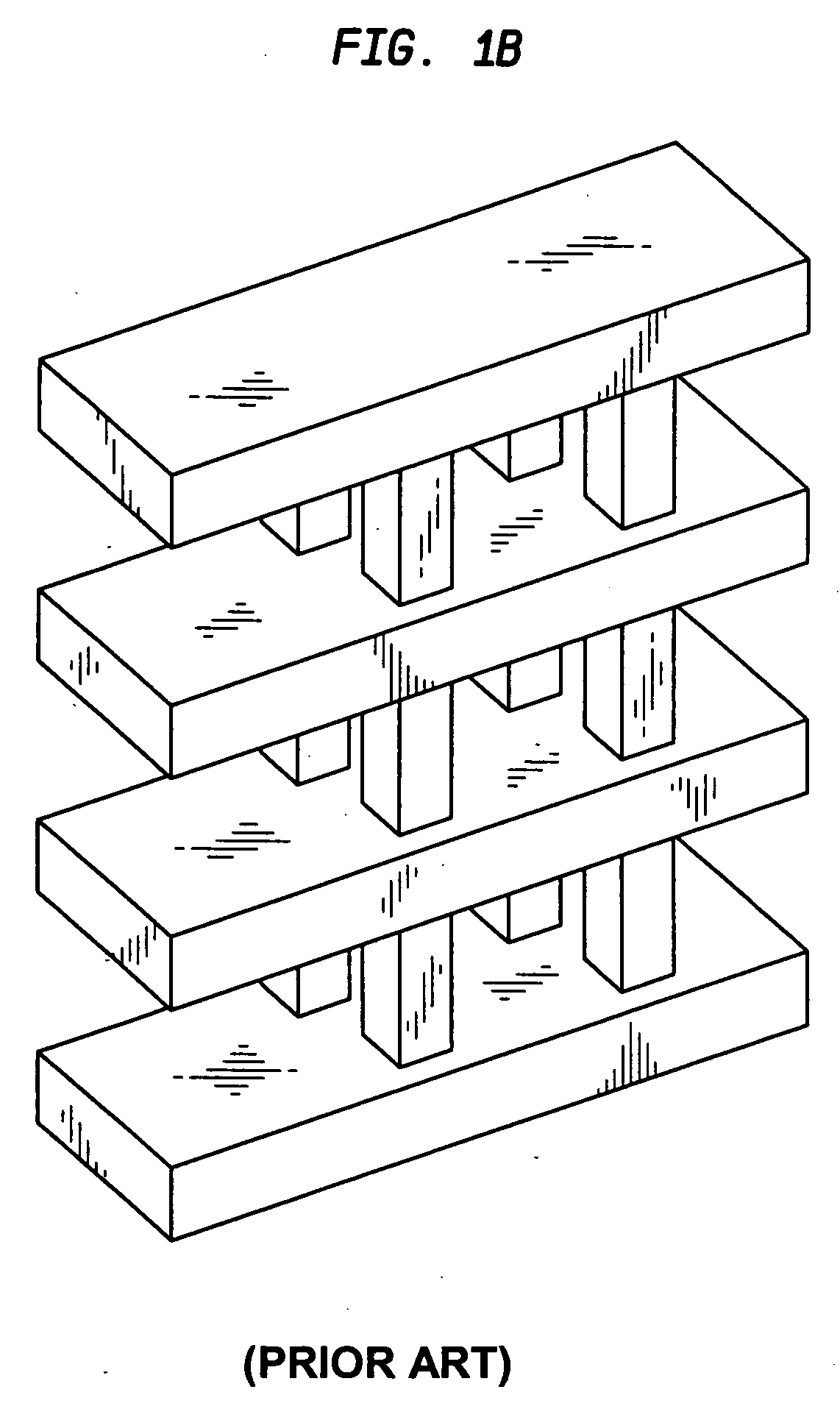

[0048] The present invention is generally related to methods for forming metal filled via-studs and conductor lines on a substrate where the via-studs and conductor lines are formed using a dual damascene method, and preferably copper metallurgy and low-k dielectric material. The present invention has particular relevance to stacked via-stud schemes which particularly use low strength low-k dielectric materials and incorporate a cantilever structure within the stacked via-stud which may serve as an effective thermal fatigue crack stop.

[0049] Particularly referring to FIG. 2, there is shown a semiconductor substrate 10 above which a sequence of dielectric layers 111, 112, 113 is deposited, subsequently patterned and metallized to form a first level of interconnection. It should be understood that a plurality of semiconductor devices may be formed in the substrate and, although not shown, are provided with a local interconnect line 101, typically tungsten with underlayers of titanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com