Hot working die steel and preparation method thereof

A technology of hot work die steel and chemical composition, applied in the direction of temperature control, etc., can solve the problems of poor thermal fatigue resistance, limited service life, limited application field, etc., to achieve excellent fatigue resistance, excellent service life, and production preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific implementation examples.

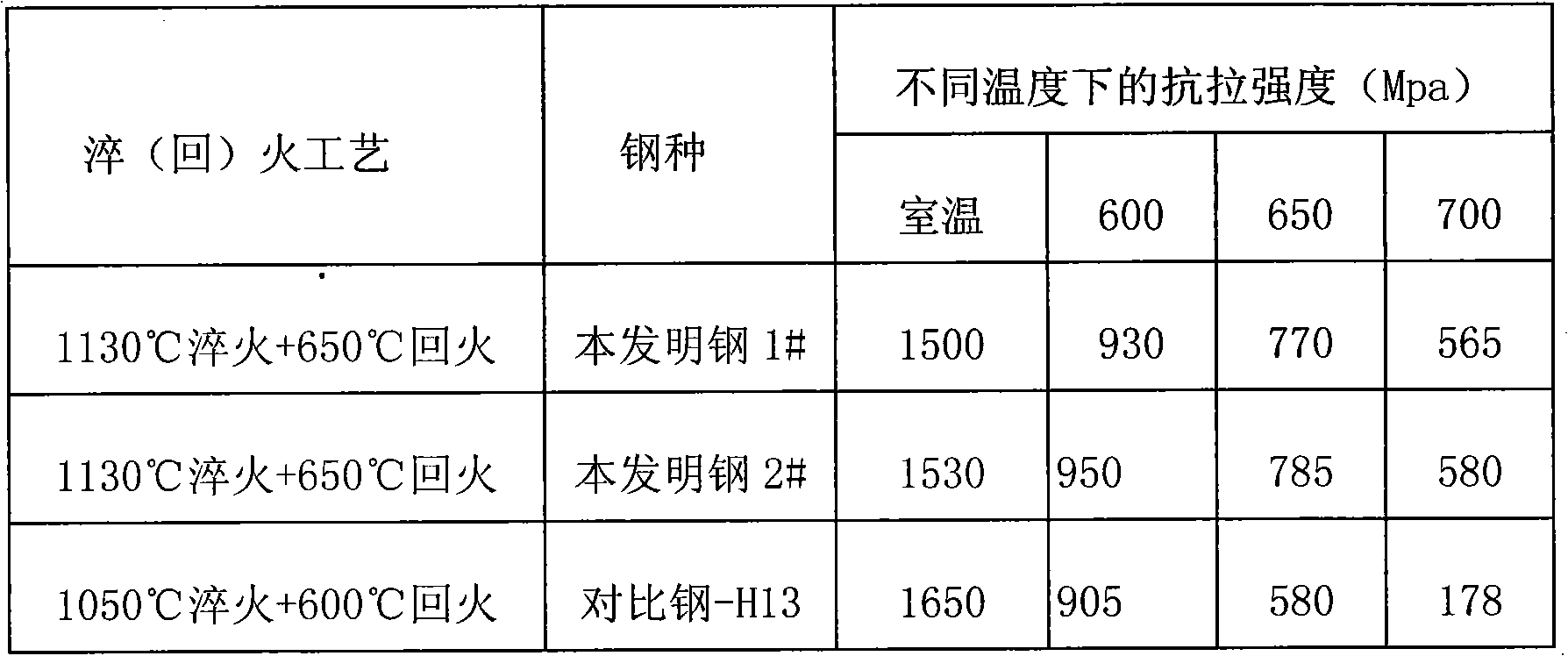

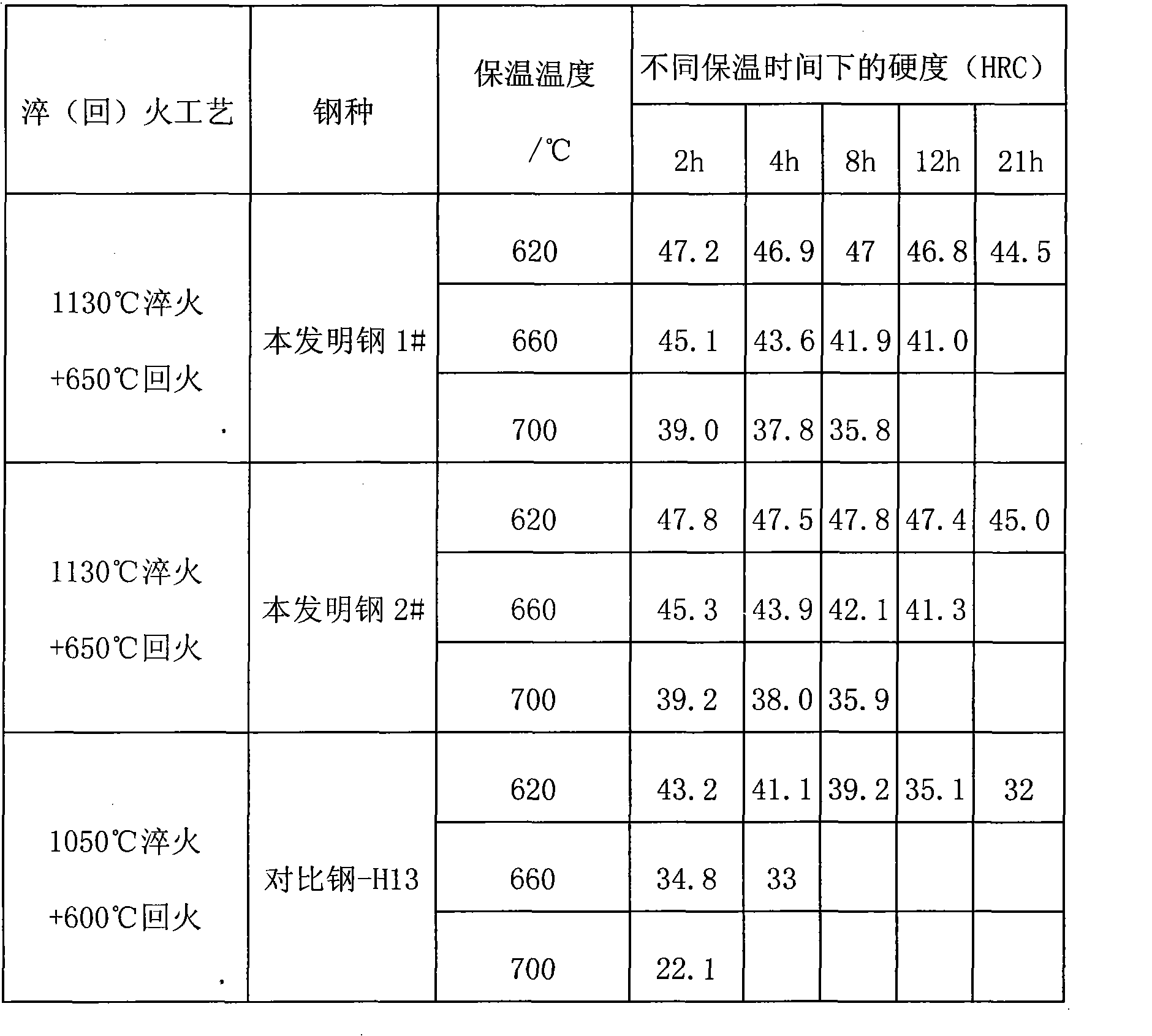

[0027] 1. The high-performance hot work die steel described in the present invention realizes high performance by optimizing the configuration of alloy components and optimizing the preparation process. Its preparation method is: (1) Smelting and alloying: smelting in an electric furnace or a converter until the chemical composition range meets the requirements, tapping, refining outside the furnace, vacuum degassing to make the gas content meet the international requirements, and then electroslag remelting Make the content of S, P and other non-metallic impurities meet the national standard requirements; (2) Forging and annealing: the electroslag ingot forging process is heated at 1140-1160°C, the initial forging temperature is 1090-1150°C, and the final forging temperature is ≥900°C; forging Post-isothermal annealing: heating temperature is 830-850°C, heat pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com