Thermal protection coating surface performance test method

A technology for surface performance and thermal protection, applied in measuring devices, thermal analysis of materials, instruments, etc., can solve the problems of short test period, long test period, and high cost, so as to save experiment cost, shorten test period, and improve thermal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

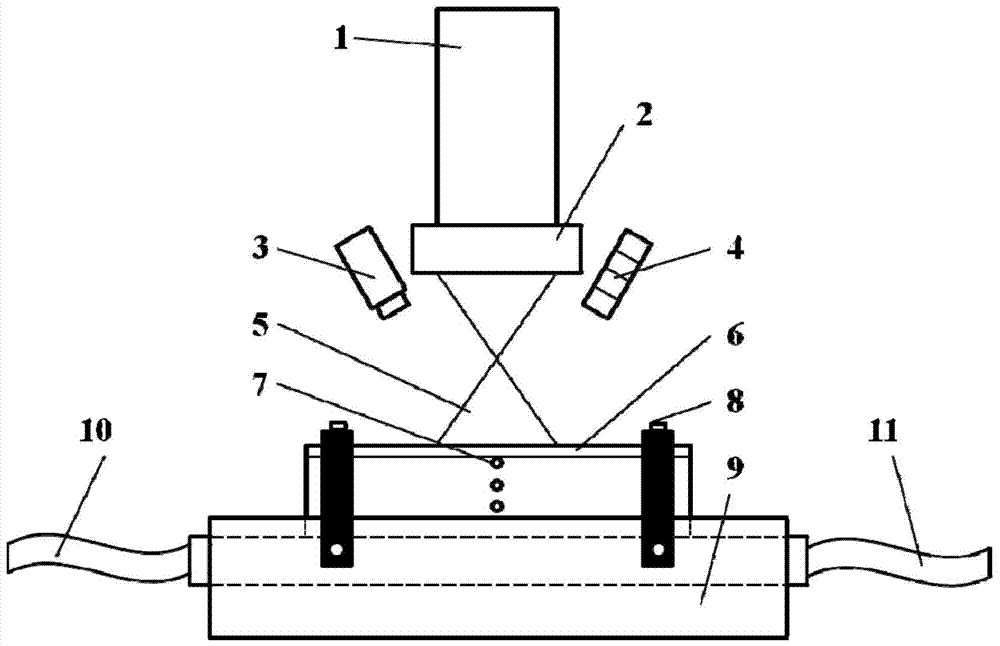

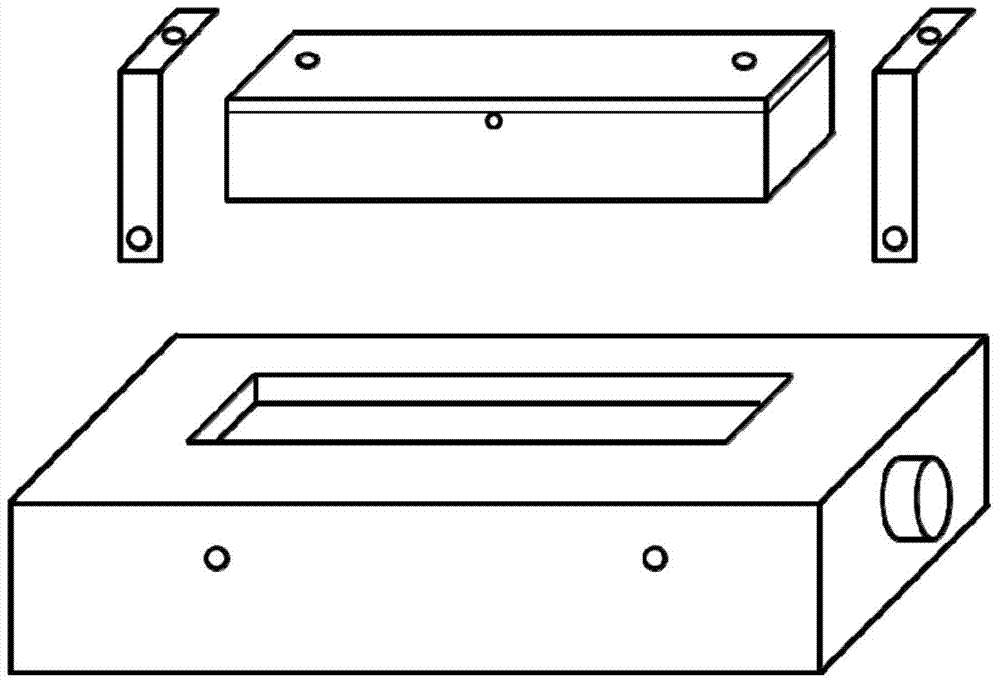

[0037] Such as figure 1 As shown, the present embodiment adopts the thermal protective coating surface performance testing device mainly by laser and laser head 1, beam conversion system 2, image acquisition system 3, infrared thermometer 4, laser beam 5, thermal protective coating to be tested Sample 6, thermocouple 7, fixing and sealing device 8, cooling base 9, cooling medium inlet 10, cooling medium outlet 11. specific:

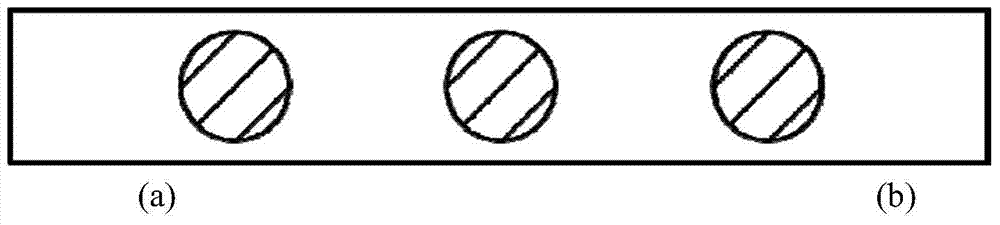

[0038] Laser 1 is a high-power solid-state continuous laser HLD1001.5 from Trumpf, Germany, and an optical fiber is used to connect the laser to the laser head, and the diameter of the optical fiber is 0.15 mm. Beam transformation system 2 transforms the laser beam distribution into a dot matrix distribution laser with 3 circular spots, distributed in a row, each spot diameter is 10mm, and the position of the transformed spot acting on the surface of the thermal protective coating is as follows: figure 2 shown. The image acquisition system 3 adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com