Method for improving efficiency of steam heating, and papermaking method

A technology of heating efficiency and steam, applied in heating devices, lighting and heating equipment, papermaking, etc., can solve the problems of reducing cleaning frequency, achieve the effect of increasing cleaning frequency, improving efficiency, and inhibiting the formation of condensed water film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

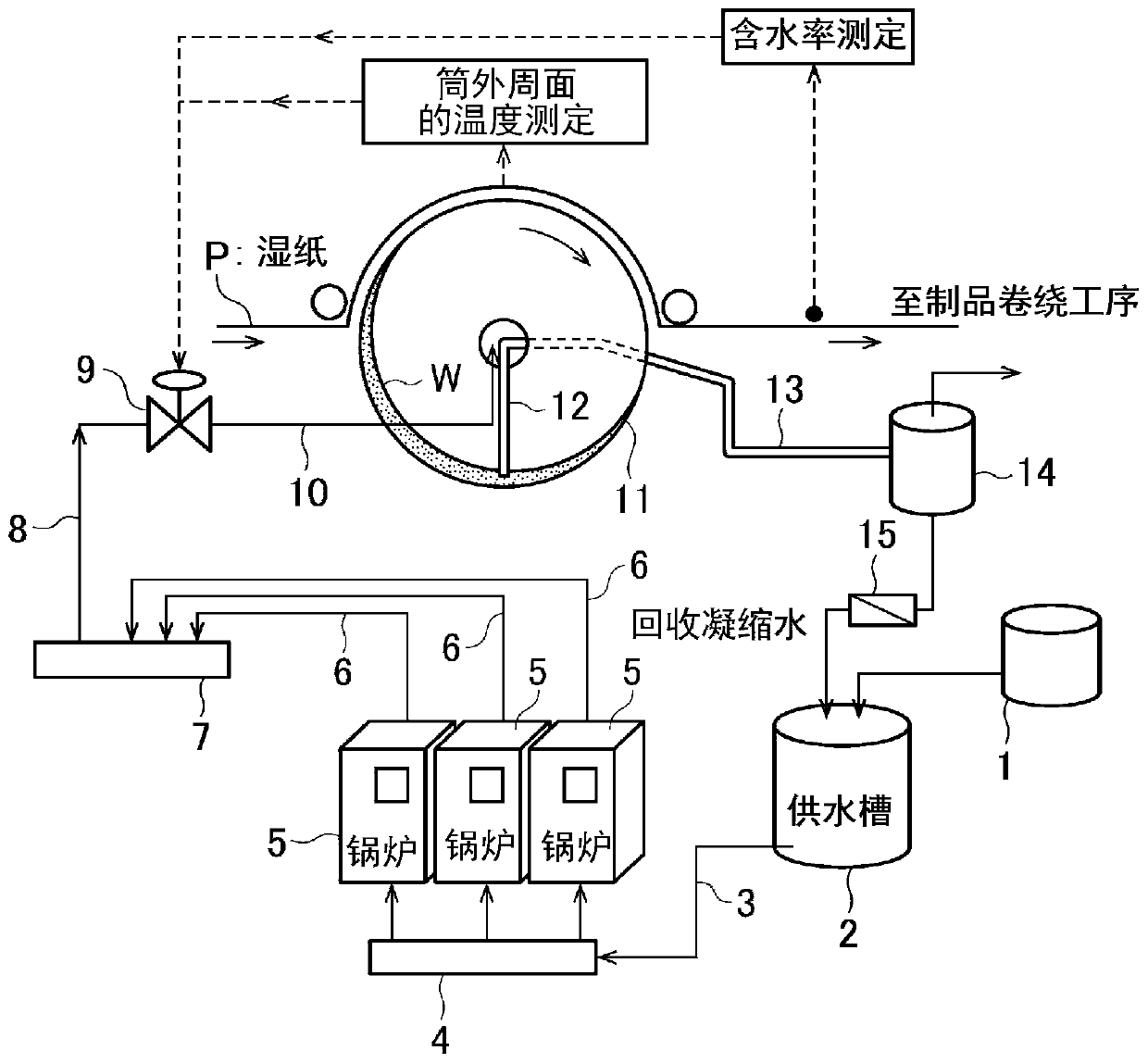

[0070] exist figure 1 In the papermaking drying equipment shown, the cylinder diameter of the Yankee dryer is set to 3m, the supply water vapor pressure is set to 0.6MPa, and the water vapor supply rate is set to about 900kg / h. The water vapor supply rate of the gram dryer is controlled by the flow regulating valve 9 so that the outer surface temperature of the cylinder becomes 100° C. and the moisture content of the dried product (paper) becomes 20 to 30%.

[0071] N-octadecenylpropane-1,3-diamine was used as polyamine.

[0072] Polyamine is added after emulsification with polyoxyethylene cocoamine. The compounding quantity of polyoxyethylene cocoamine was set to 15 weight part with respect to 100 weight part of polyamines.

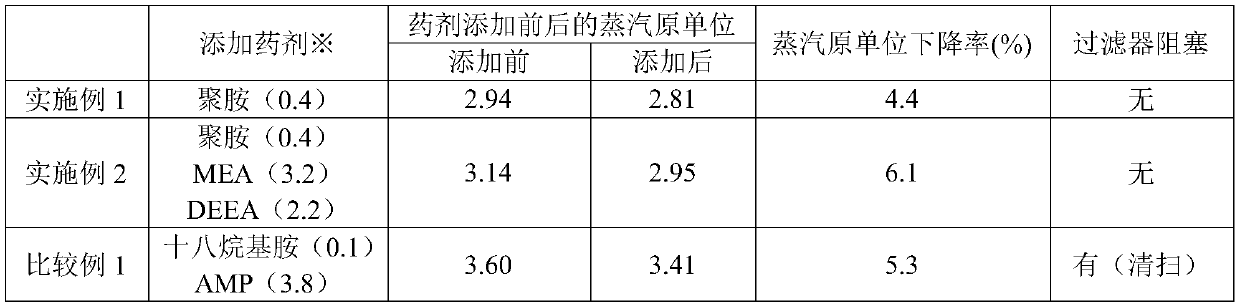

[0073] When polyamine was added to the steam head 7 so that the polyamine relative to the amount of steam was 0.4 ppm, the original unit of steam before the addition was 2.94, but after the addition of the polyamine, it improved to 2.81. During the te...

Embodiment 2

[0075] In Example 1, except that 3.2 ppm of MEA and 2.2 ppm of DEEA were added as neutralizing amines in combination with polyamine, the operation was carried out in the same manner as in Example 1, and the steam unit and filter before and after addition of chemicals were investigated. With or without blockage. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com