Preparation method of titanium zirconium base alloy

A titanium-zirconium-based alloy and alloy technology are applied in the field of alloy material preparation to achieve the effect of improving strength and maintaining alloy plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

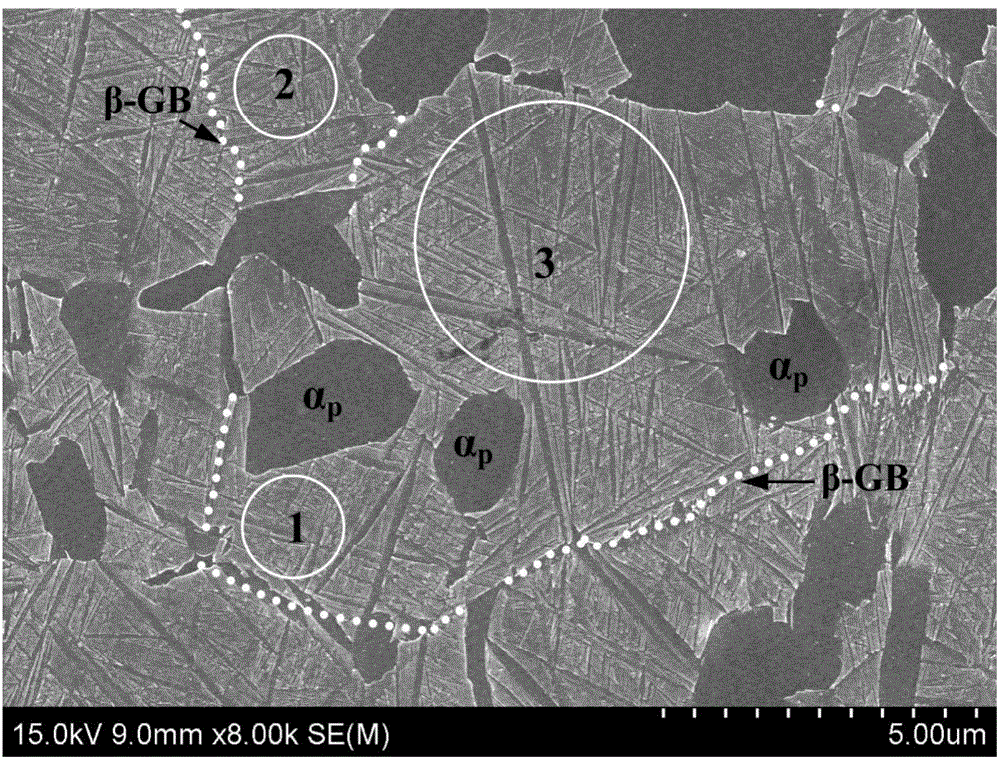

Image

Examples

Embodiment 1

[0020] Put various raw materials such as titanium, zirconium, aluminum, vanadium, etc. into a non-consumable electric arc furnace at a melting temperature of 2100°C, and smelt three times for 15 minutes each time to obtain Ti with a uniform composition. 45 Zr 47 al 5 V 3 alloy ingot. Coat the surface of the above-mentioned alloy ingot with high-temperature antioxidant (titanium alloy high-temperature forging antioxidant protective coating, produced by Shanghai Runer Metal Surface Materials Co., Ltd.), and then heat it in a box-type heating furnace to 1050 ° C, keep it warm for 1 hour, and then open it. The billet is forged, and after two times of upsetting and drawing, it is rolled with a high-power rolling mill, and the deformation reaches 81%, and finally the plate-shaped Ti 45 Zr 47 al 5 V 3 alloy. After the above-mentioned plate alloy is cooled, the surface of the alloy is trimmed to remove the antioxidant on the surface. Put the above-mentioned alloy with the anti...

Embodiment 2

[0023] Put various raw materials such as titanium, zirconium, aluminum, vanadium, etc. into a non-consumable electric arc furnace at a melting temperature of 2300°C, and smelt three times for 20 minutes each time to obtain Ti with uniform composition. 62 Zr 30 al 5 V 3 alloy ingot. Coat the surface of the above-mentioned alloy ingot with high-temperature antioxidant (titanium alloy high-temperature forging antioxidant protective coating, produced by Shanghai Runer Metal Surface Materials Co., Ltd.), and then heat it in a box-type heating furnace to 1070 ° C, keep it for 3 hours, and then open it. The billet is forged, and after two times of upsetting and drawing, it is rolled with a high-power rolling mill, and the deformation reaches 83%, and finally the plate-like Ti 62 Zr 30 al 5 V 3 alloy. After the above-mentioned plate alloy is cooled, the surface of the alloy is trimmed to remove the antioxidant on the surface. Put the above-mentioned alloy with the anti-oxidant...

Embodiment 3

[0026] Put various raw materials such as titanium, zirconium, aluminum, vanadium, etc. into a non-consumable electric arc furnace at a melting temperature of 2050°C, and smelt three times for 25 minutes each time to obtain Ti with uniform composition. 41 Zr 51 al 5 V 3 alloy ingot. Coat the surface of the above-mentioned alloy ingot with high-temperature antioxidant (titanium alloy high-temperature forging antioxidant protective coating, produced by Shanghai Runer Metal Surface Material Co., Ltd.), and then heat it in a box-type heating furnace to 1105 ° C, keep it for 2 hours, and then open it. The billet is forged, and after two times of upsetting and drawing, it is rolled with a high-power rolling mill, and the deformation reaches 90%, and finally the plate-like Ti 41 Zr 51 al 5 V 3 alloy. After the above-mentioned plate alloy is cooled, the surface of the alloy is trimmed to remove the antioxidant on the surface. Put the above-mentioned alloy with the anti-oxidant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Full length | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com