Novel regeneration cast aluminum alloy for structural application

一种铝合金、再生铝的技术,应用在测试金属、材料检验品等方向,能够解决低凝固速率、高收缩倾向等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

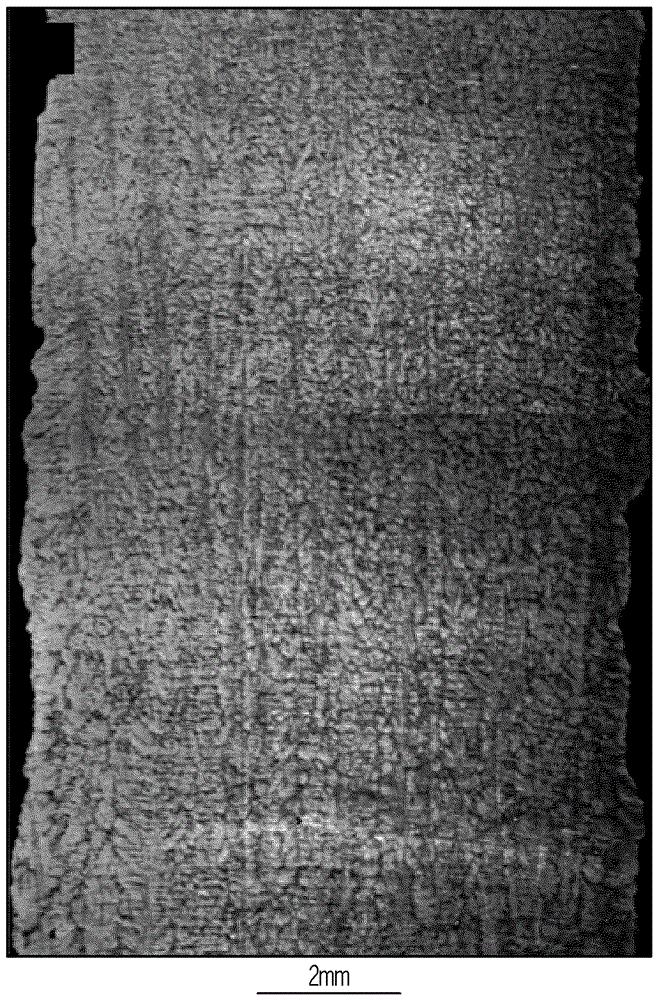

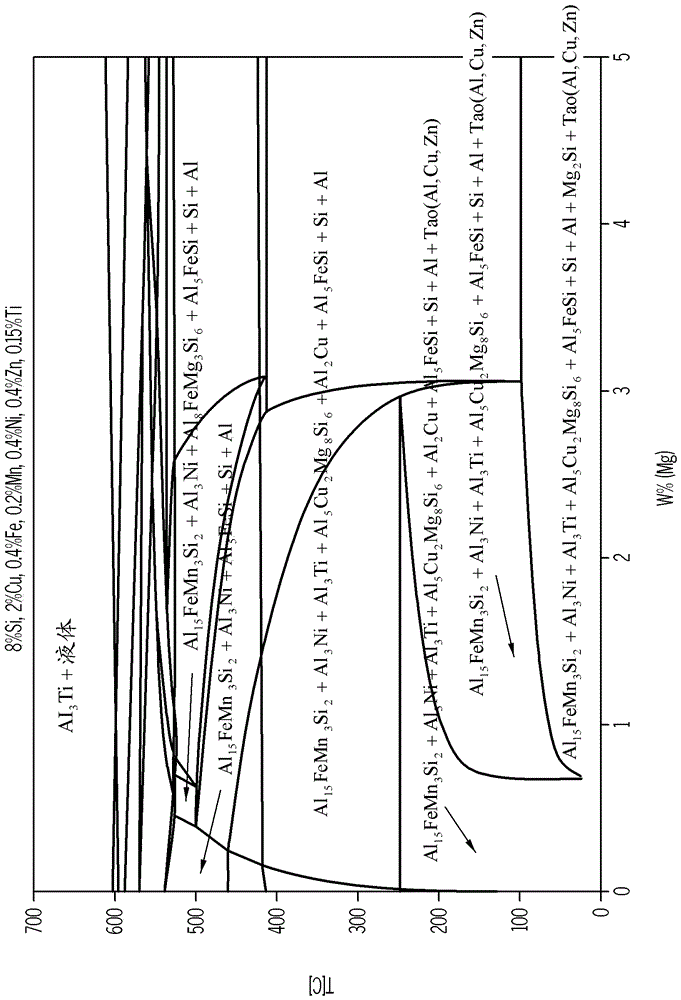

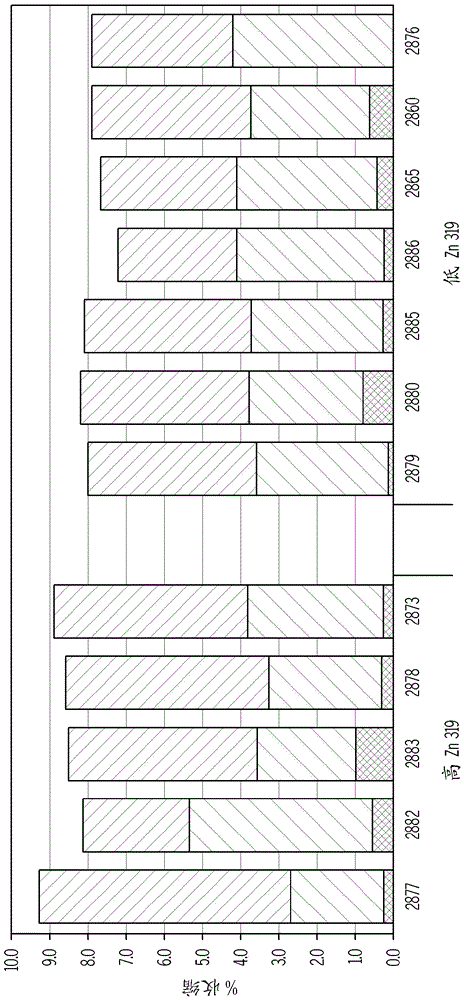

[0055] First refer to figure 1 , Shows a simplified view of a four-cylinder automobile internal combustion engine cylinder block 100. The block 100 includes, among other parts, a crankcase 110, a crankshaft bearing 120, a camshaft bearing 130 (in the case of an engine with overhead valves and push rods), a water-cooled jacket 140, and a flywheel housing 150 And the part of the cylinder bore 160. These bores 160 may include an alloyed surface layer (not shown), which is integrally formed with the base of each bore 160, or formed as a separate insert or sleeve sized to fit securely therein. The cylinder block 100 is preferably cast from the secondary aluminum alloy discussed herein, wherein the alloy is preferably an Al-Si casting alloy (such as alloys 319, 354, 356, 360, 380, and 390). In a preferred form, the mechanical properties (such as strengthening, ductility, fatigue resistance, etc.) of the cylinder block 100 made of recycled aluminum alloy raw materials are improved by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear shrinkage | aaaaa | aaaaa |

| Linear shrinkage | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com