High-nickel positive active material of surface-modified lithium ion battery and preparation method of positive active material

A cathode active material, lithium-ion battery technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as inability to reduce alkalinity, and achieve simple and easy modification methods, moisture absorption Problem Solving, Solving the Effect of Water Absorption by Alkaline Substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

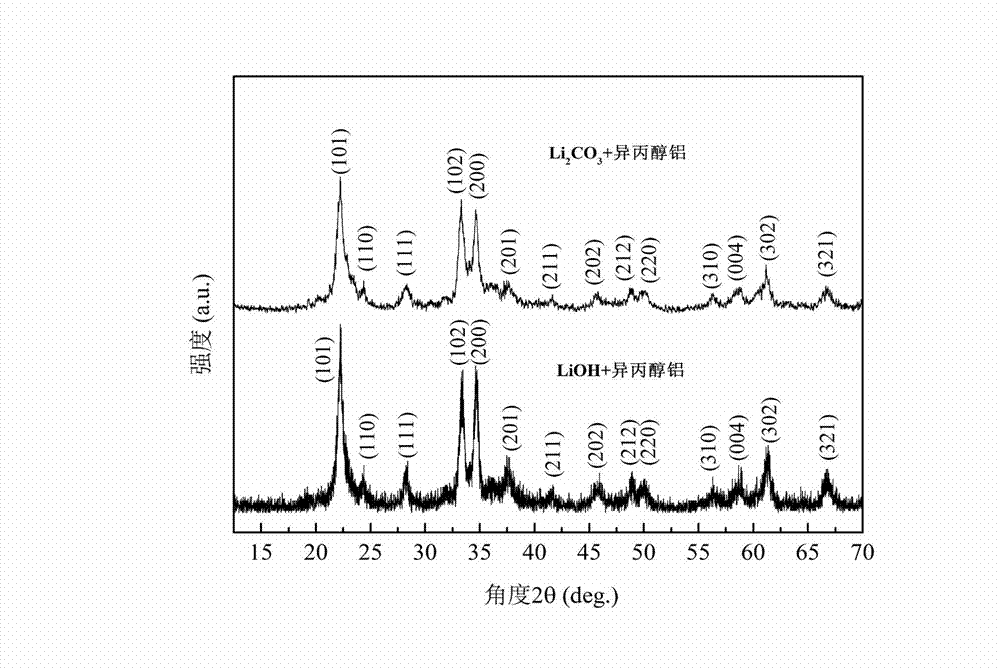

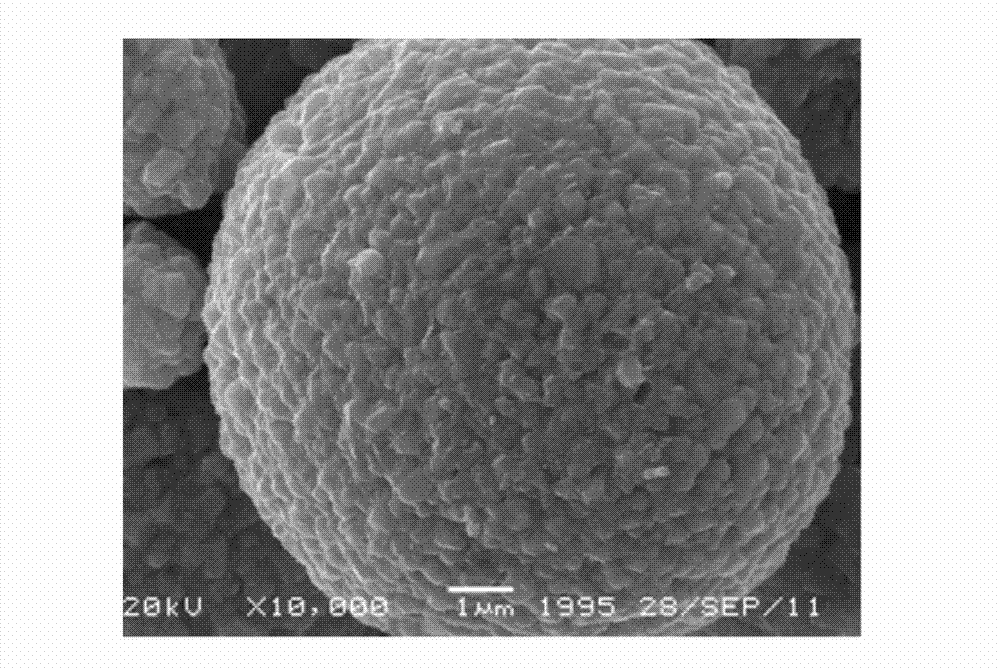

[0032] A surface-modified lithium-ion battery high-nickel positive electrode active material of the present invention, its matrix material is high-nickel positive electrode active material LiNi 0.8 co 0.15 al 0.05 o 2 , where the Al element can be replaced by one or more of Al, Mn, Mg, Ti; the surface of the matrix material is evenly coated with a lithium ion conductor compound, and the lithium ion conductor compound is LiAlO 2 ; The content of the total impurity lithium in the high-nickel positive electrode active material of the surface-modified lithium-ion battery is 0.083%, which is 0.27 times that before modification. The impurity lithium salt in the present embodiment refers to Li 2 CO 3 and LiOH as the main component of the basic impurities, the content of the total lithium impurities refers to the basic impurities Li 2 CO 3 and the mass content of lithium in LiOH. Before modification, the matrix material LiNi 0.8 co 0.15 al 0.05 o 2 The content of total impu...

Embodiment 2

[0041] A surface-modified lithium-ion battery high-nickel positive electrode active material of the present invention, its matrix material is high-nickel positive electrode active material LiNi 0.8 co 0.15 al 0.05 o 2 , where the Al element can be replaced by one or more of Al, Mn, Mg, Ti; the surface of the matrix material is evenly coated with a lithium ion conductor compound, and the lithium ion conductor compound is LiAlO 2 ; The content of the total impurity lithium in the high-nickel cathode active material of the surface-modified lithium-ion battery is 0.0847%, which is 0.28 times that before modification. The impurity lithium salt in the present embodiment refers to Li 2 CO 3 Alkaline impurities with LiOH as the main components; the content of total impurity lithium refers to the alkaline impurities Li 2 CO 3 and the mass content of lithium in LiOH.

[0042] The preparation method of the surface-modified lithium-ion battery high-nickel positive electrode active ...

Embodiment 3

[0048] In this example, the coating additive in Example 2 was changed to micron-sized aluminum hydroxide (1 μm-2 μm); other preparation processes and process parameters were the same as in Example 2.

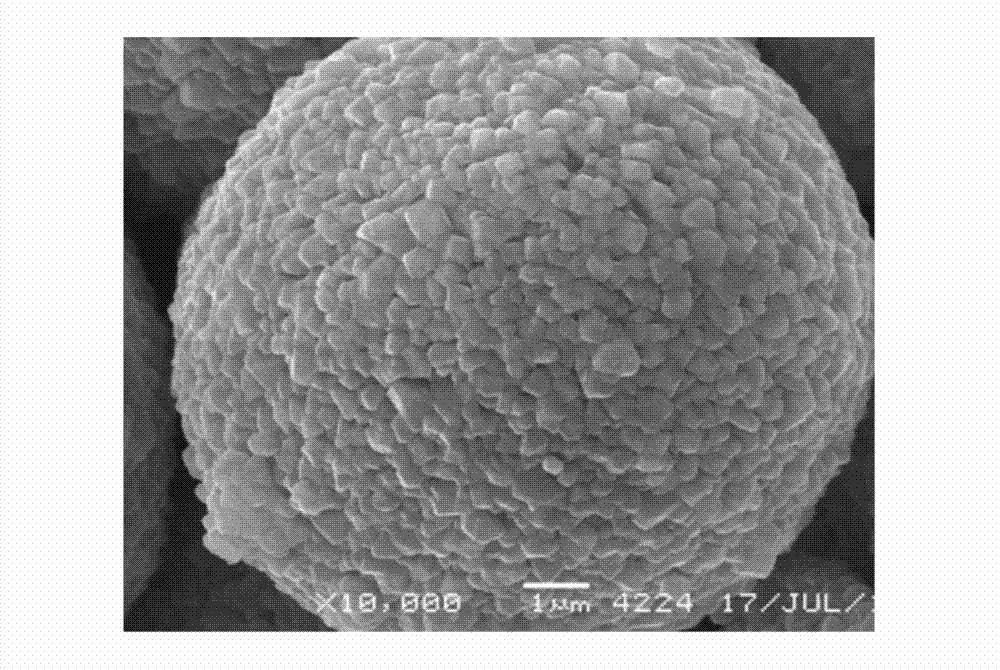

[0049] After surface modification, the lithium-ion high-nickel positive electrode active material LiNi prepared in this embodiment 0.8 co 0.15 Al 0.05 o 2 The pH value dropped from 12.2 to 11.9, and the content of total impurity lithium in surface alkaline substances was 0.36 times that before modification. From the effect of reducing alkalinity, this embodiment is slightly worse than embodiment 1 and embodiment 2.

[0050] Figure 11 LiNi in this example 0.8 co 0.15 Al 0.05 o 2 Modified SEM photos; from Figure 11 It can be seen that some fine powder remains on the surface of the positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com