Method for preparing tin antimony oxide nanometer powder in low-temperature ball-milling way

A nano-powder, tin-antimony oxide technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems that are not suitable for large-scale industrial production, difficult to dope, uniform and controllable, and serious agglomeration and other problems, to achieve the effect of small agglomeration, uniform and controllable doping, and low agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

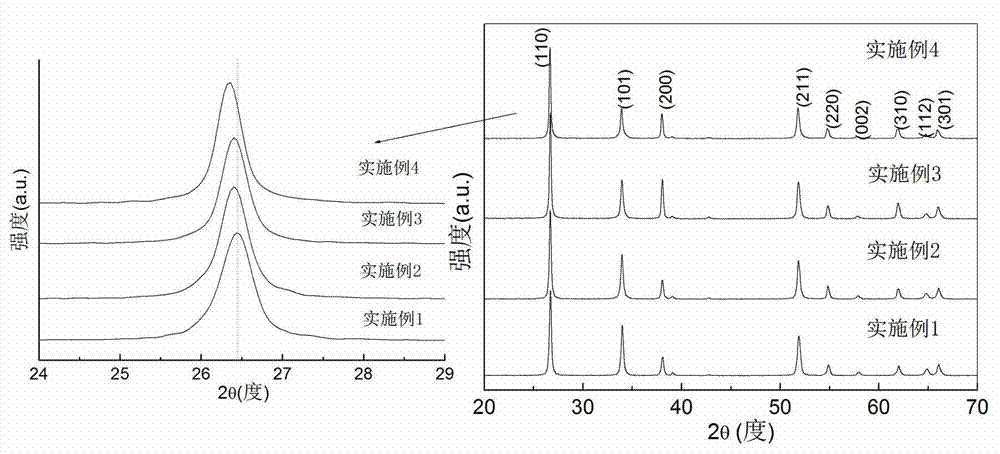

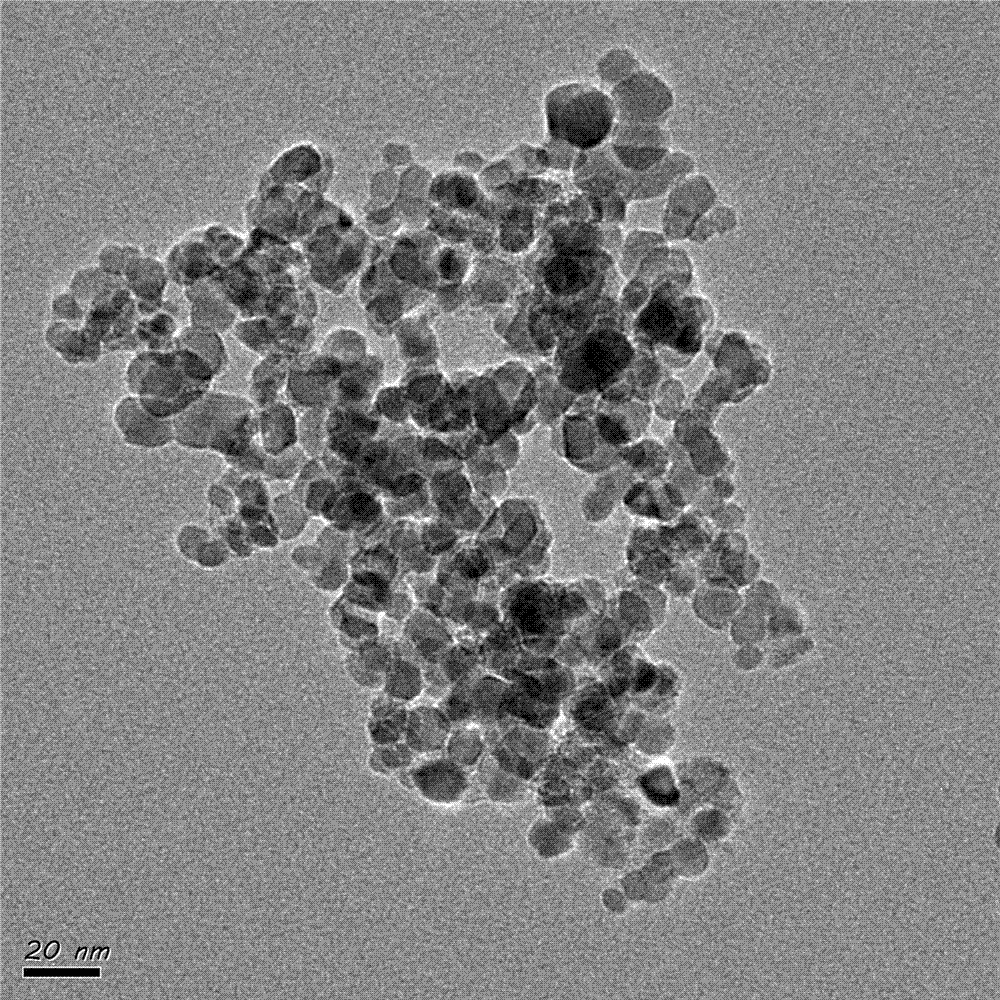

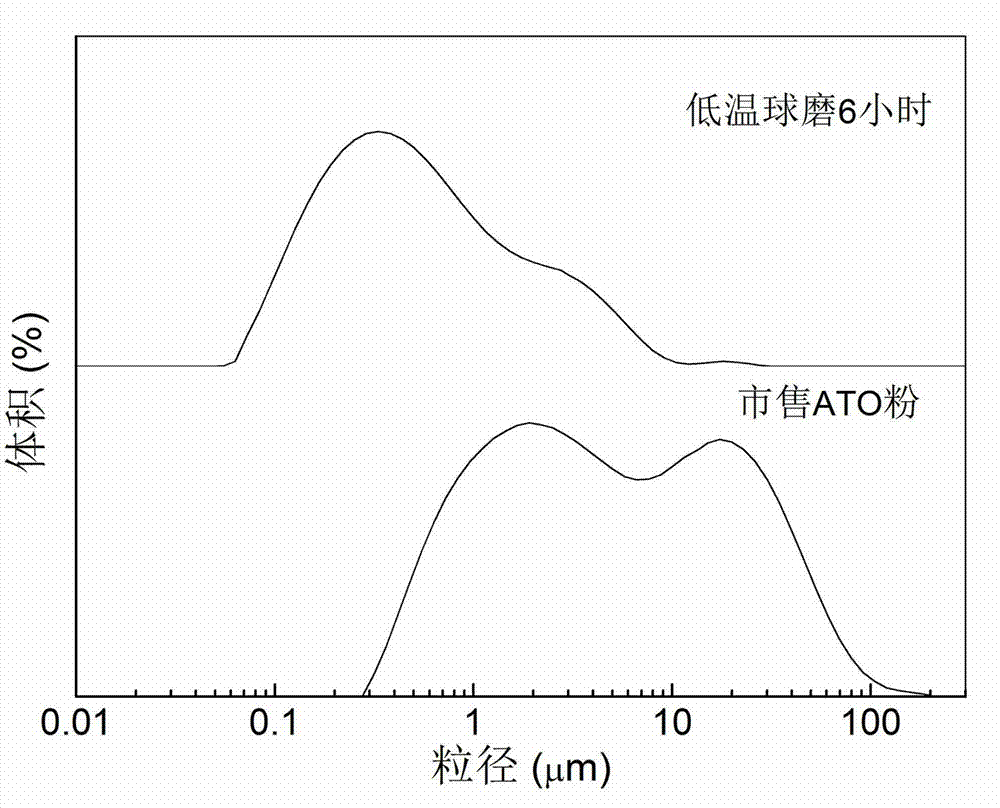

Embodiment 1

[0031] Use high-purity tin oxide powder and antimony oxide powder with a particle size of 200 mesh as the raw material powder, and configure the raw material with the atomic ratio of antimony element and tin element at 20:80, and mix the zirconia grinding ball with a diameter of 5mm and the raw material powder according to the weight ratio of the ball material Add 10:1 into the ball milling tank; feed liquid nitrogen into the ball milling tank, immerse the raw material powder and zirconia balls in the liquid nitrogen, and keep the liquid level stable; start ball milling at constant temperature for 30 minutes, control the ball milling time for 6 hours and ball milling The rotation speed is 600 rpm, and the temperature in the ball mill tank is -180°C; the powder after ball milling is placed in an environment of 50°C for nitrogen desorption treatment for 3 hours, and the obtained tin antimony oxide nanopowder is collected, antimony doped The content is 20at.%, and the average grai...

Embodiment 2

[0034] Use high-purity tin oxide powder and antimony oxide powder with a particle size of 400 mesh as raw material powder, and configure the raw material with an atomic ratio of antimony element to tin element of 10:90, and mix zirconia grinding balls with a diameter of 5mm and raw material powder according to the weight ratio of the ball and material Add 20:1 into the ball milling tank; feed liquid nitrogen into the ball milling tank, immerse the raw material powder and zirconia balls in the liquid nitrogen, and keep the liquid level stable; start ball milling at constant temperature for 30 minutes, control the ball milling time for 6 hours and ball milling The rotation speed is 300 rpm, and the temperature in the ball mill tank is -185°C; the powder after ball milling is placed in an environment of 100°C for nitrogen desorption treatment for 2 hours, and the obtained tin antimony oxide nanopowder is collected, antimony doped The content is 10at.%, and the average grain size i...

Embodiment 3

[0038] Use high-purity tin oxide powder and antimony oxide powder with a particle size of 200 mesh as the raw material powder, and configure the raw material with an atomic ratio of antimony element to tin element of 30:70, and mix the zirconia grinding ball with a diameter of 5mm and the raw material powder according to the weight ratio of the ball material Add 20:1 into the ball milling tank; feed liquid nitrogen into the ball milling tank, immerse the raw material powder and zirconia balls in the liquid nitrogen, and keep the liquid level stable; start ball milling at constant temperature for 30 minutes, control the ball milling time for 4 hours and ball milling The rotation speed is 600 rpm, and the temperature in the ball mill tank is -180°C; the powder after ball milling is placed in an environment of 200°C for nitrogen desorption treatment for 0.5 hours, and the obtained tin antimony oxide nanopowder is collected, antimony doped The content is 30 at.%, and the average gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com