Low-alloy ultrahigh-strength wear-resistant steel and production method thereof

An ultra-high strength, production method technology, applied in the field of metal materials, can solve the problems of wear resistance, impact performance, plastic toughness, etc., to achieve high wear resistance, simple manufacturing and processing technology, high toughness and wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

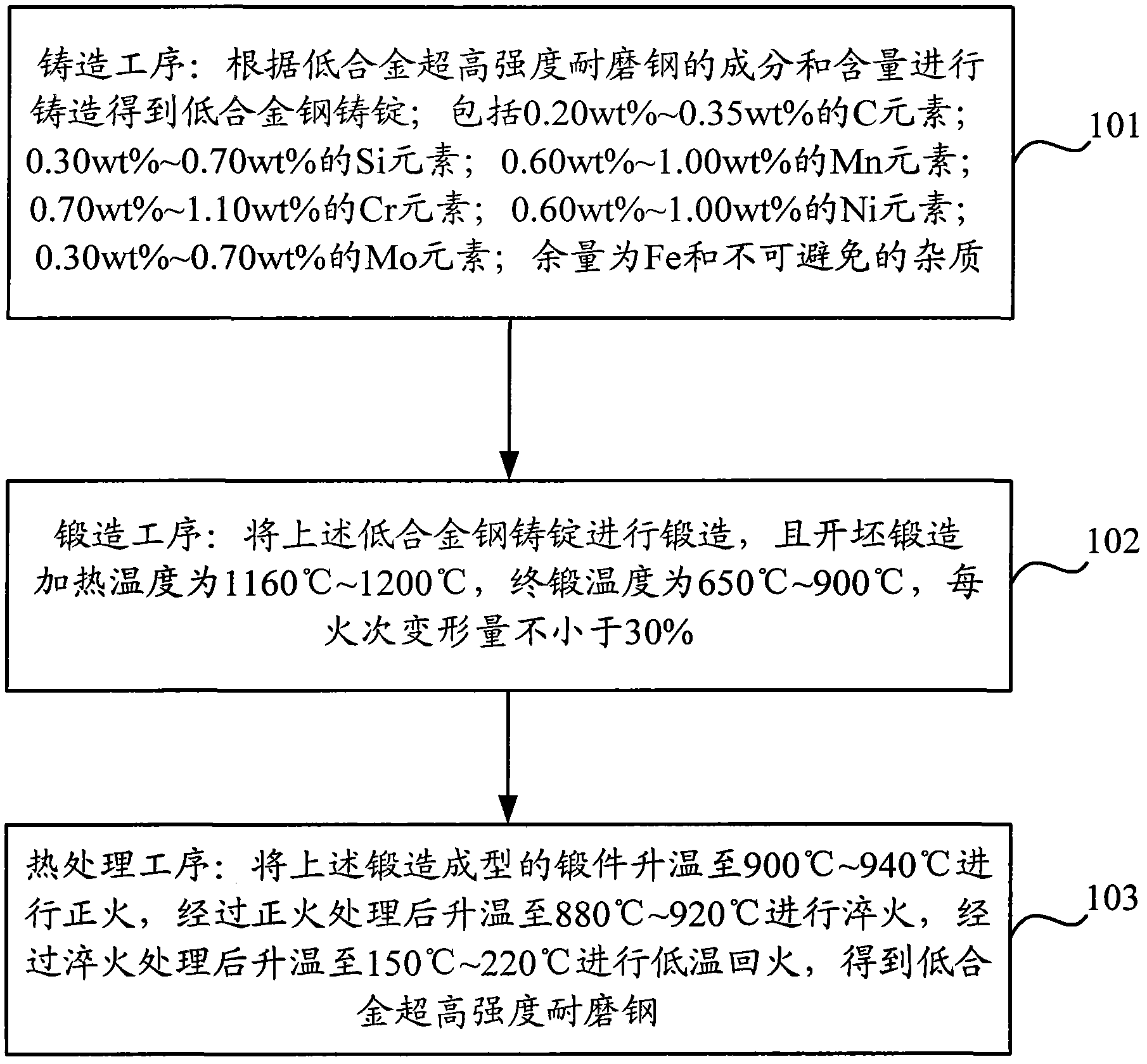

Method used

Image

Examples

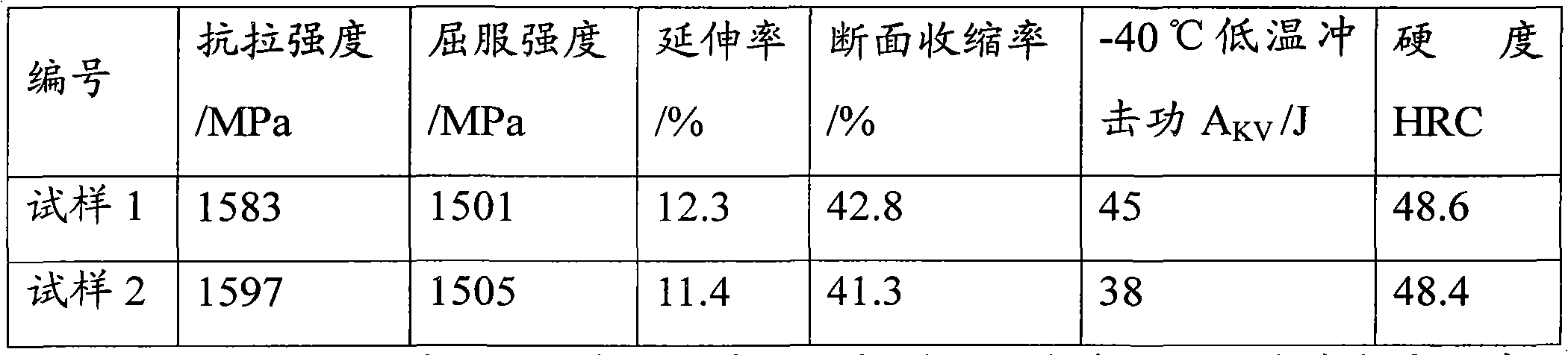

Embodiment 1

[0058]Based on the composition and content of the above-mentioned low-alloy high-strength and high-toughness steel, Embodiment 1 of the present invention provides a production method of low-alloy ultra-high-strength wear-resistant steel to achieve a low-alloy ultra-high-strength wear-resistant steel with a yield strength of 1500 MPa; and The low-alloy ultra-high-strength wear-resistant steel can solve the problems of alloy chemical element content, material forming process, and increase the strength level; the method performs large-deformation forging on the as-cast material, and the forging can break the as-cast structure and refine the grain size. grains, increase dislocation density, improve strength, and heal some defects formed by casting to prevent the decrease of plasticity and toughness; after forging, quenching + low-temperature tempering heat treatment is carried out to obtain tempered sorbite structure, which can obtain ultra-high strength , while maintaining a certa...

Embodiment 2

[0075] Step 1. Cast a low-alloy ultra-high-strength wear-resistant steel ingot with the composition shown in Table 1, and the specification of the ingot is Φ100×110mm, and control the melting and pouring process.

[0076] Table 1 Low alloy steel chemical composition (wt%)

[0077] C

[0078] Step 2, forging the ingot obtained in step 1.

[0079] In the embodiment of the present invention, the heating temperature for blank forging is 1160-1200°C, the final forging temperature is 700°C, the deformation per firing is not less than 30%, and the cross-sectional specification of the forging is 16×80mm.

[0080] Step 3. Heating the forging obtained in step 2 to 920° C., keeping it warm for 3 hours, and cooling to room temperature in the air; this process is a normalizing process.

[0081] Step 4. Heating the forged piece obtained in Step 3 to 900° C., keeping it warm for 2 hours, and rapidly cooling to room temperature in water; this process is a quenching treatment proc...

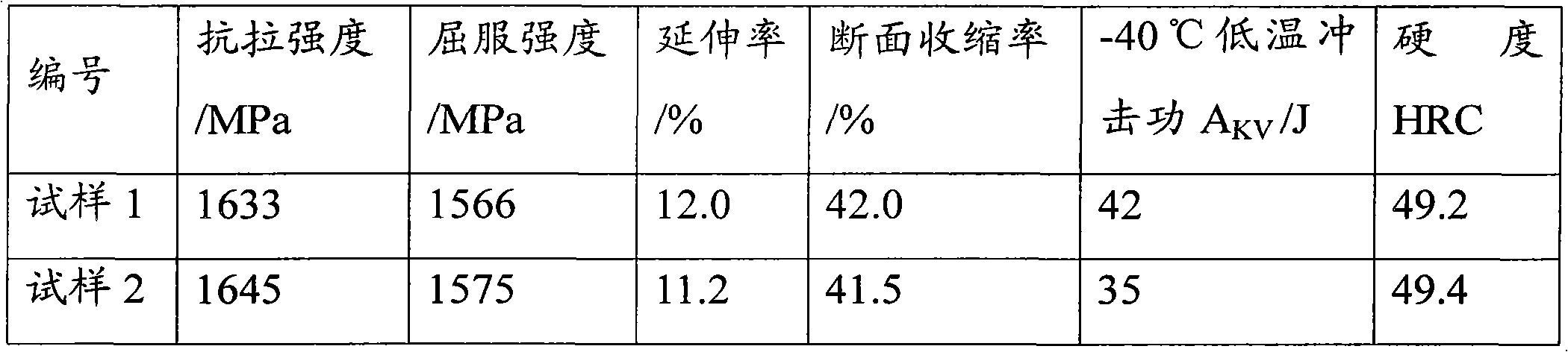

Embodiment 3

[0089] Step 1. Cast a low-alloy ultra-high-strength wear-resistant steel ingot with the composition shown in Table 3, and the specification of the ingot is Φ100×110mm, and control the melting and pouring process.

[0090] Table 3 Chemical Composition of Low Alloy Steel (wt%)

[0091] C

S

P

mn

Si

Cr

Ni

Mo

Al

La

0.20

0.005

0.022

0.78

0.62

0.95

0.93

0.66

0.042

0.0013

[0092] Step 2, forging the ingot obtained in step 1.

[0093] In the embodiment of the present invention, the heating temperature for blank forging is 1160-1200°C, the final forging temperature is 750°C, the deformation per firing is not less than 30%, and the cross-sectional specification of the forging is 16×80mm.

[0094] Step 3. Heating the forging obtained in step 2 to 930° C., keeping it warm for 3 hours, and cooling to room temperature in the air; this process is a normalizing process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com