High-chrome corrosion-resisting high-strength pipeline steel and manufacturing method thereof

A high-strength pipeline steel and manufacturing method technology, applied in the direction of manufacturing converters, improving process efficiency, etc., can solve problems such as low manganese diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

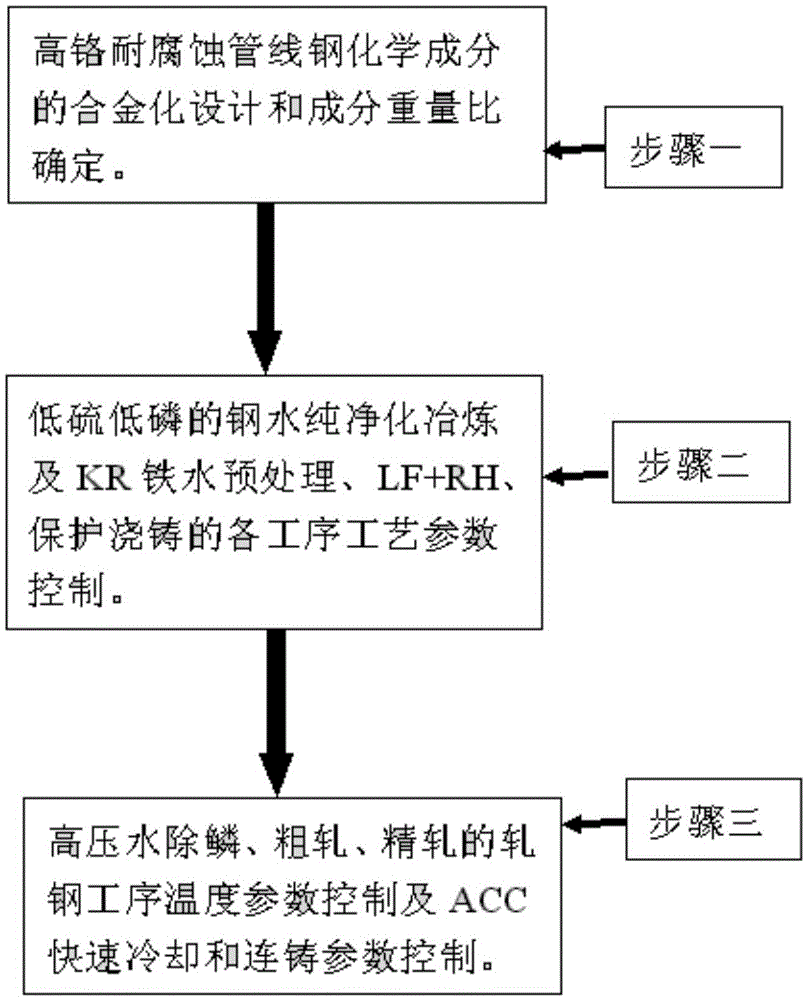

Method used

Image

Examples

Embodiment 1

[0033]Take the following components by weight percentage: carbon 0.06%, silicon 0.25%, manganese 0.40%, phosphorus ≤ 0.006%, sulfur ≤ 0.003%, chromium 1.5%, copper 0.25%, niobium 0.045%, titanium 0.015%, nitrogen ≤ 0.006 %, the balance is iron and unavoidable impurities.

[0034] a. Hot metal pretreatment: KR conducts deep desulfurization. After treatment, the S in the hot metal is ≤0.0030%, the slag is cleaned, the bright surface of the hot metal reaches more than 90%, and the amount of slag in the hot metal is minimized.

[0035] b. Converter smelting: adopt double slag operation with large amount of slag, and adopt automatic model for converter bottom blowing. Do not add iron sheets or ores two minutes before pulling carbon. Try to pull the carbon out of the steel at one time, avoid spot blowing, and prevent the molten steel from being over-oxidized. Before tapping, ensure that the post-converter stirring time is not less than 2 minutes. The binary basicity of the slag a...

Embodiment 2

[0054] Each component is taken according to the following mass percentages: carbon 0.04%, silicon 0.55%, manganese 0.15%, phosphorus 0.02%, sulfur 0.003%, chromium 0.8%, copper 0.55%, niobium 0.020%, titanium 0.008%, nitrogen 0.010%, and the balance is Iron and unavoidable impurities.

[0055] (a) KR hot metal pretreatment desulfurization: oxygen blowing time is 6min, oxygen supply intensity is 20000m 3 / h, sulfur content in hot metal after treatment ≤ 0.0030%;

[0056] (b) Converter smelting: Double slag operation is adopted, the bottom blowing of the converter adopts an automatic model, a converter with a nominal capacity of 200t is used, two-thirds of the ore is added before dephosphorization, and the last third is added after dephosphorization; Blow once when the mass is 0.20%, the target carbon content is ≤0.02%, phosphorus content is ≤0.005%, and the tapping temperature is 1600°C; the slag blocking plug and the slag blocking rod are used to tap the steel; 1200kg of lime...

Embodiment 3

[0061] The components are taken according to the following mass percentages: 0.08% carbon, 0.15% silicon, 0.95% manganese, 0.010% phosphorus, 0.002% sulfur, 2.0% chromium, 0.15% copper, 0.090% niobium, 0.035% titanium, 0.008% nitrogen, and more The amount is iron and unavoidable impurities.

[0062] (a) KR hot metal pretreatment desulfurization: oxygen blowing time is 7min, oxygen supply intensity is 24000m 3 / h, sulfur content in hot metal after treatment ≤ 0.0030%;

[0063] (b) Converter smelting: Double slag operation is adopted, the bottom blowing of the converter adopts an automatic model, a converter with a nominal capacity of 200t is used, two-thirds of the ore is added before dephosphorization, and the last third is added after dephosphorization; Blow once when the mass is 0.20%, the target carbon content is ≤0.02%, phosphorus content is ≤0.005%, and the tapping temperature is 1650°C; the slag blocking plug and the slag blocking rod are used to tap the steel; 1200kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com