Preparation method of low-alloy manganese martensite wear resistant cast steel

A tempered martensite and low-alloy technology, which is applied in the field of low-alloy wear-resistant cast steel preparation, can solve the problems of high cost, large heat treatment energy consumption, and many alloy elements in wear-resistant cast steel, so as to achieve low cost and low alloy element Less content, excellent combination of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the low-alloy manganese series tempered martensitic wear-resistant cast steel proposed by the present invention comprises the following steps:

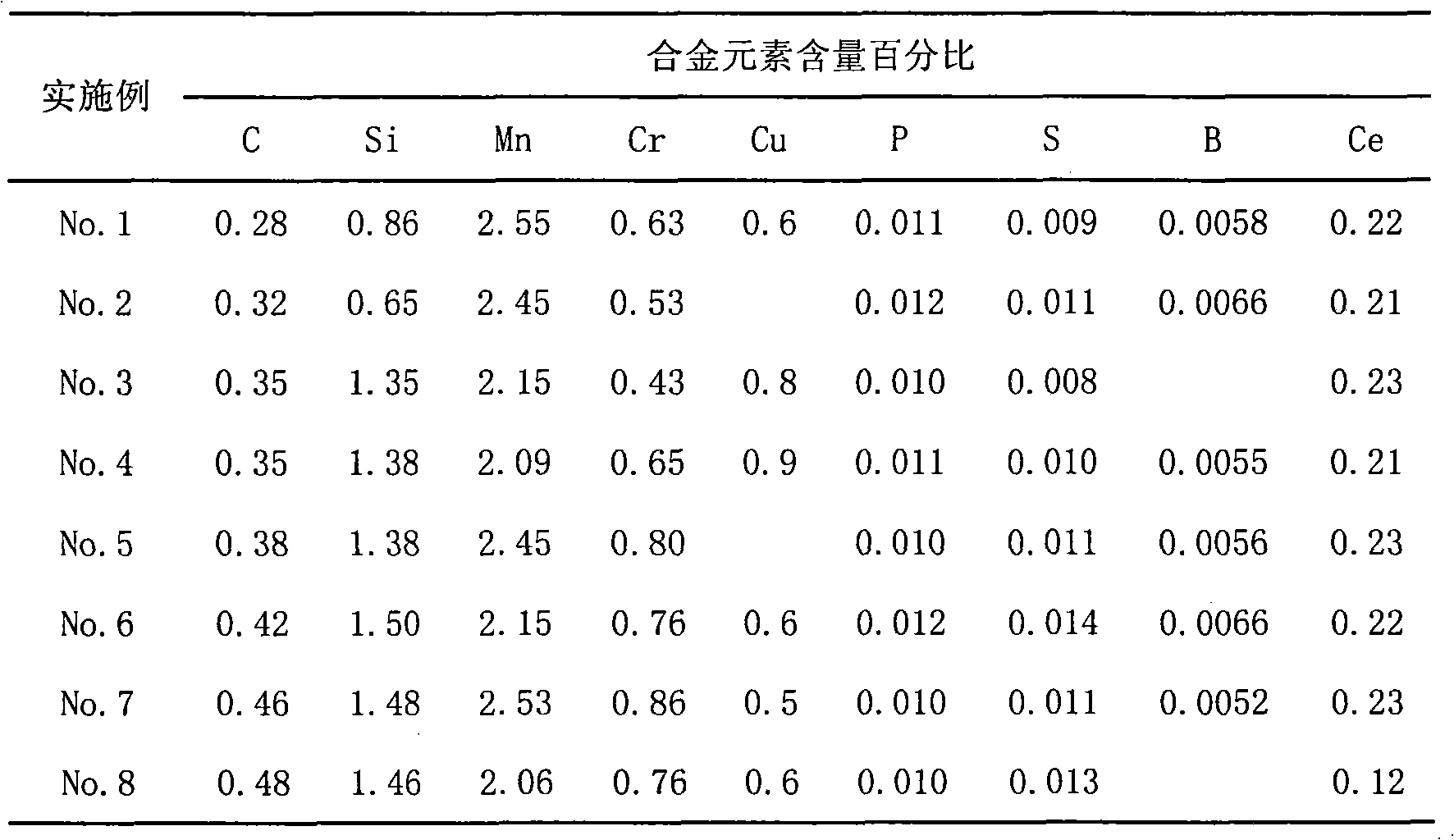

[0021] (1) After being smelted by the conventional steelmaking process, it is cast by sand casting or precision casting process, and the weight percentage of each component in the steel is:

[0022] C: 0.28~0.48wt.%;

[0023] Si: 0.20~1.50wt.%;

[0024] Mn: 1.85~3.50wt.%;

[0025] Cr: 0.30~0.90wt.%;

[0026] Cu: 0~0.90wt.%;

[0027] P: 0.01~0.03wt.%;

[0028] S: 0.01~0.03wt.%;

[0029] B: 0~0.008wt.%;

[0030] Rare earth Ce: 0.05~0.25wt.%;

[0031] The rest is Fe;

[0032] (2) Heating the above-mentioned cast steel to 830-900°C for austenitization, keeping the temperature for 2-5 hours, and then cooling to room temperature for annealing;

[0033] (3) Heating the above-mentioned cast steel to 830-900°C for austenitization, and water quenching to 80-150°C after heat preservation for 1-2 hours; ...

Embodiment 1

[0039] (1) After being smelted by the conventional steelmaking process, it is casted by sand casting or precision casting process, and the Kiel sample is poured at the same time.

[0040] (2) Heat the above-mentioned cast steel to 880°C for austenitization, keep it warm for 3 hours, and then cool it to room temperature for annealing.

[0041] (3) Heat the above-mentioned cast steel to 860°C to austenitize, keep it warm for 1 hour and then quench to 120°C.

[0042] (4) Heating the above-mentioned cast steel to 220° C., holding the temperature for 3 hours and performing tempering treatment.

Embodiment 2

[0044] (1) After being smelted by the conventional steelmaking process, it is casted by sand casting or precision casting process, and the Kiel sample is poured at the same time.

[0045] (2) Heat the above-mentioned cast steel to 880°C for austenitization, keep it warm for 3 hours, and then cool it to room temperature for annealing.

[0046] (3) Heat the above-mentioned cast steel to 860° C. to austenitize, and then quench to 110° C. after holding for 1 hour.

[0047] (4) Heating the above-mentioned cast steel to 230° C., holding the temperature for 3 hours and performing tempering treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com