Preparation method for air-cooled lower bainite/martensite multi-phase wear-resistant cast steel

A technology of bainite and martensite, which is applied in the field of preparation of bainite/martensite composite phase wear-resistant cast steel under air cooling, can solve the problems of application limitations and low impact toughness, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

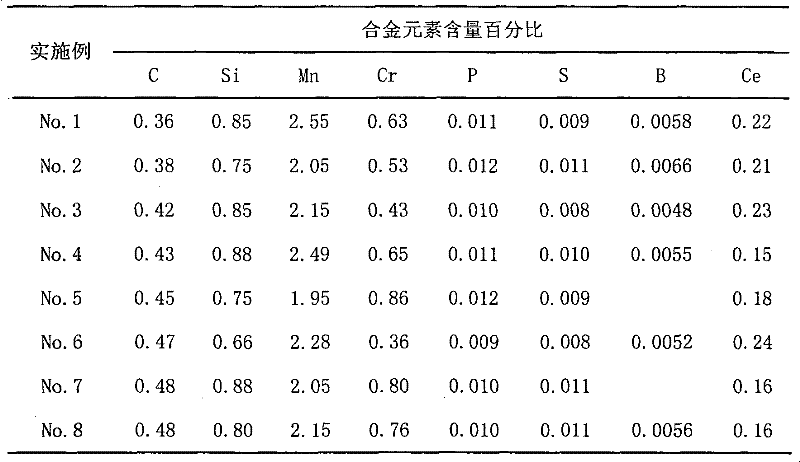

[0021] The preparation method of the air-cooled bainite / martensite composite phase wear-resistant cast steel proposed by the present invention comprises the following steps:

[0022] (1) After being smelted by the conventional steelmaking process, it is casted by sand casting or precision casting process, so that the weight percentage of each component in the cast steel is:

[0023] C: 0.35-0.48wt.%;

[0024] Si: 0.10-0.90wt.%;

[0025] Mn: 1.90-3.50wt.%;

[0026] Cr: 0.30-0.80wt.%;

[0027] P: 0.01-0.03wt.%;

[0028] S: 0.01-0.03wt.%;

[0029] B: 0-0.008wt.%;

[0030] Rare earth Ce: 0.01-0.26wt.%;

[0031] The rest is Fe;

[0032] (2) Heating the above-mentioned cast steel to 850-900° C. for austenitization, keeping the temperature for 2-5 hours, and then cooling the furnace to room temperature for annealing treatment.

[0033] (3) Heating the above-mentioned cast steel to 830-860°C for austenitization, keeping it warm for 1-2 hours, then air cooling or air cooling to...

Embodiment 1

[0039] (1) After being smelted by the conventional steelmaking process, it is casted by sand casting or precision casting process, and the Kiel sample is poured at the same time.

[0040] (2) Heat the above-mentioned cast steel to 880°C for austenitization, keep it warm for 3 hours, and then cool it to room temperature for annealing.

[0041] (3) Heat the above-mentioned cast steel to 860°C for austenitization, keep it warm for 1 hour, and air-cool to 120°C.

[0042] (4) Heating the above-mentioned cast steel to 220° C., holding the temperature for 3 hours and performing tempering treatment.

Embodiment 2

[0044] (1) After being smelted by the conventional steelmaking process, it is casted by sand casting or precision casting process, and the Kiel sample is poured at the same time.

[0045] (2) Heat the above-mentioned cast steel to 880°C for austenitization, keep it warm for 3 hours, and then cool it to room temperature for annealing.

[0046] (3) Heat the above-mentioned cast steel to 860°C for austenitization, keep it warm for 1 hour, and air-cool to 110°C.

[0047] (4) Heating the above-mentioned cast steel to 230° C., holding the temperature for 3 hours and performing tempering treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com