sic f Interface Modification Methods of /sic Composite Materials

A composite material and modification technology, which is applied in the field of interface modification of SiCf/SiC composite materials, can solve the problems of adverse effects on material properties and strong interface bonding, and achieve the effects of shortening the preparation period, improving the interface bonding and reducing the porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

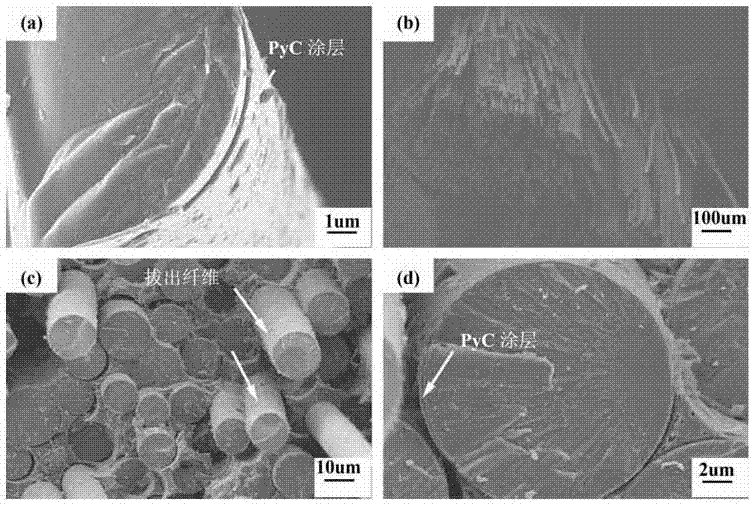

Embodiment 1

[0037] A kind of SiC of the present invention f The interface modification method of / SiC composite material comprises the following steps:

[0038] (1) The PyC coating was prepared on the surface of the SiC fiber in the SiC fiber preform by LPCVD (low pressure chemical vapor deposition). In the CVD deposition furnace, the chemical vapor deposition was carried out by the differential pressure method, the deposition temperature was 900 ° C, the deposition time was 5 h, the deposition pressure was 2000 Pa, and the flow rate of propylene was 200 L h -1 , the nitrogen flow rate is 100L·h -1 , to obtain a SiC fiber preform with PyC coating, that is, SiC f / PyC intermediates.

[0039] (2) SiC obtained in step (1) f / PyC intermediate placed in LPVCS (liquid polycarbosilane containing vinyl) impregnation solution, vacuum impregnated for 24h. Take out the vacuum-impregnated intermediate and put it into a graphite mold, and carry out cross-linking molding under a flowing nitrogen a...

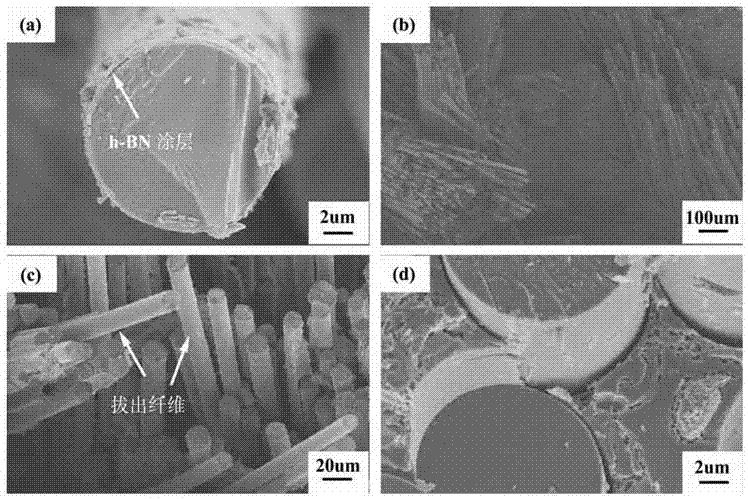

Embodiment 2

[0044] A kind of SiC of the present invention f The interface modification method of / SiC composite material comprises the following steps:

[0045] (1) The h-BN coating was prepared on the surface of the SiC fiber in the SiC fiber preform by using the LPCVD process. The specific steps were: using boron trichloride and ammonia as the source gas, nitrogen and hydrogen as the dilution gas, and the silicon carbide fiber The braided piece is placed in a CVD deposition furnace, and the chemical vapor deposition is carried out by the differential pressure method. The deposition temperature is 700 ° C, the deposition time is 4 h, the deposition pressure is 1000 Pa, and the flow rate of boron trichloride is 0.6 L h -1 , the flow rate of ammonia gas is 1.8L·h -1 , the flow rate of hydrogen is 6L·h -1 , the nitrogen flow rate is 6L·h -1 , to obtain a SiC fiber preform with h-BN coating, that is, SiC f / h-BN intermediate.

[0046] (2) SiC in step (1) f / h-BN intermediate placed in ...

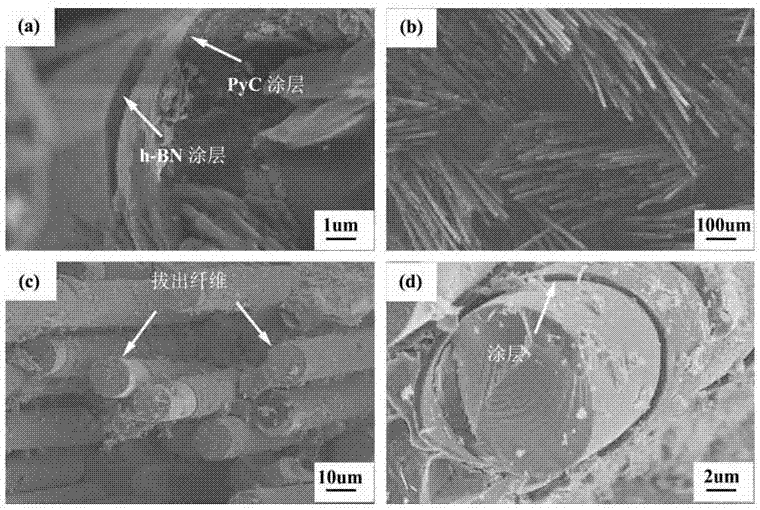

Embodiment 3

[0051] A kind of SiC of the present invention f The interface modification method of / SiC composite material comprises the following steps:

[0052] (1) The PyC coating was prepared on the surface of the SiC fiber in the SiC fiber preform by LPCVD process. The specific steps were as follows: using propylene as the source gas and nitrogen as the dilution gas, placing the silicon carbide fiber braid in the CVD deposition furnace, using Chemical vapor deposition was carried out by differential pressure method, the deposition temperature was 950 °C, the deposition time was 2 h, the deposition pressure was 3000 Pa, and the flow rate of propylene was 400 L h -1 , the nitrogen flow rate is 300L·h -1 , to obtain a SiC fiber preform with PyC coating, that is, SiC f / PyC intermediates.

[0053] (2) SiC obtained in step (1) by LPCVD process f / PyC intermediate surface to prepare h-BN coating, the specific steps are: using boron trichloride and ammonia as source gas, nitrogen and hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com