Steel for ball mill steel ball and preparation method thereof

A ball mill and steel ball technology, applied in the field of iron and steel metallurgy, can solve the problems of high chemical composition alloy elements, low production efficiency, large quality fluctuations, etc., and achieve the effects of high comprehensive performance, improved toughness, and high strength wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

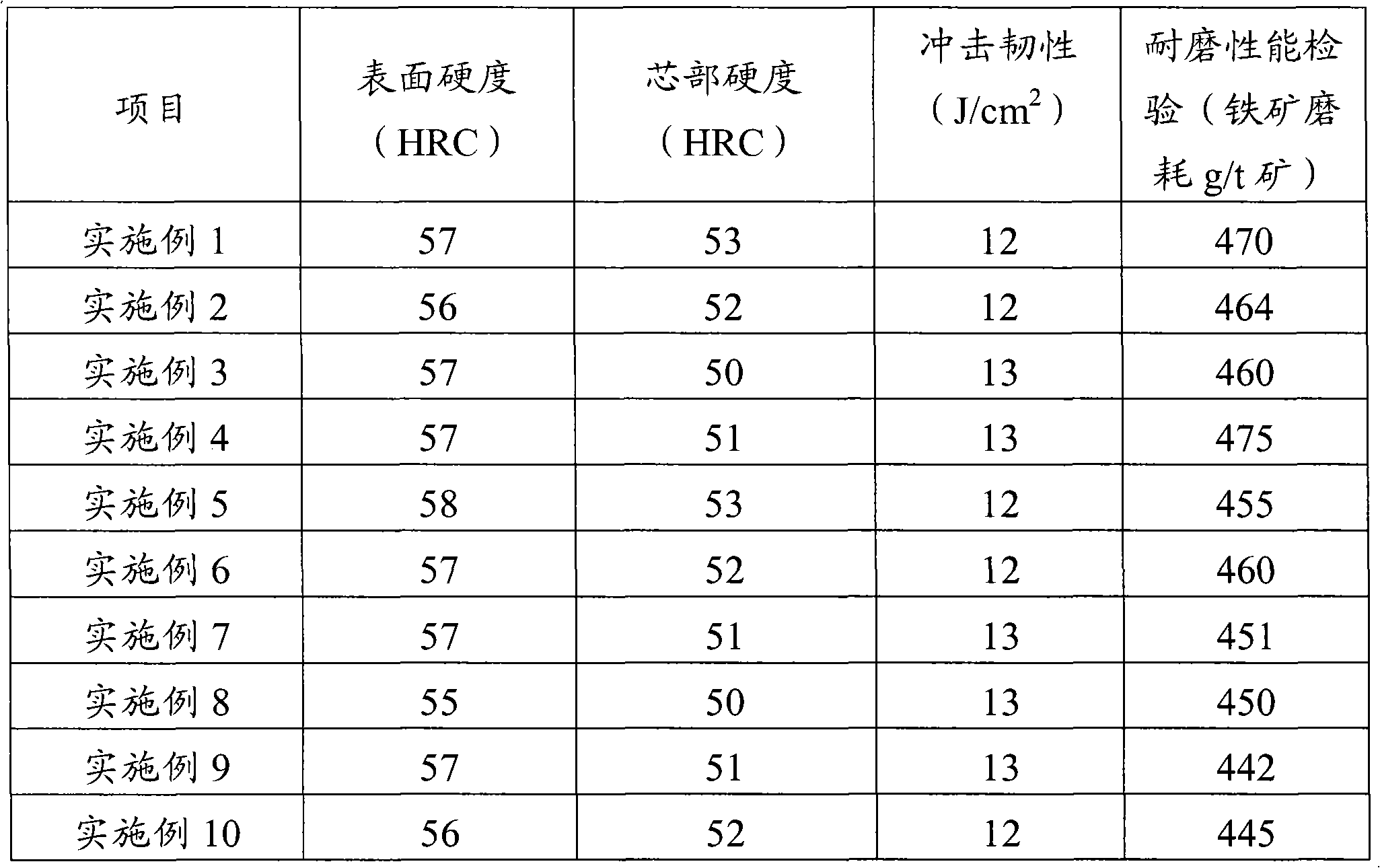

Examples

preparation example Construction

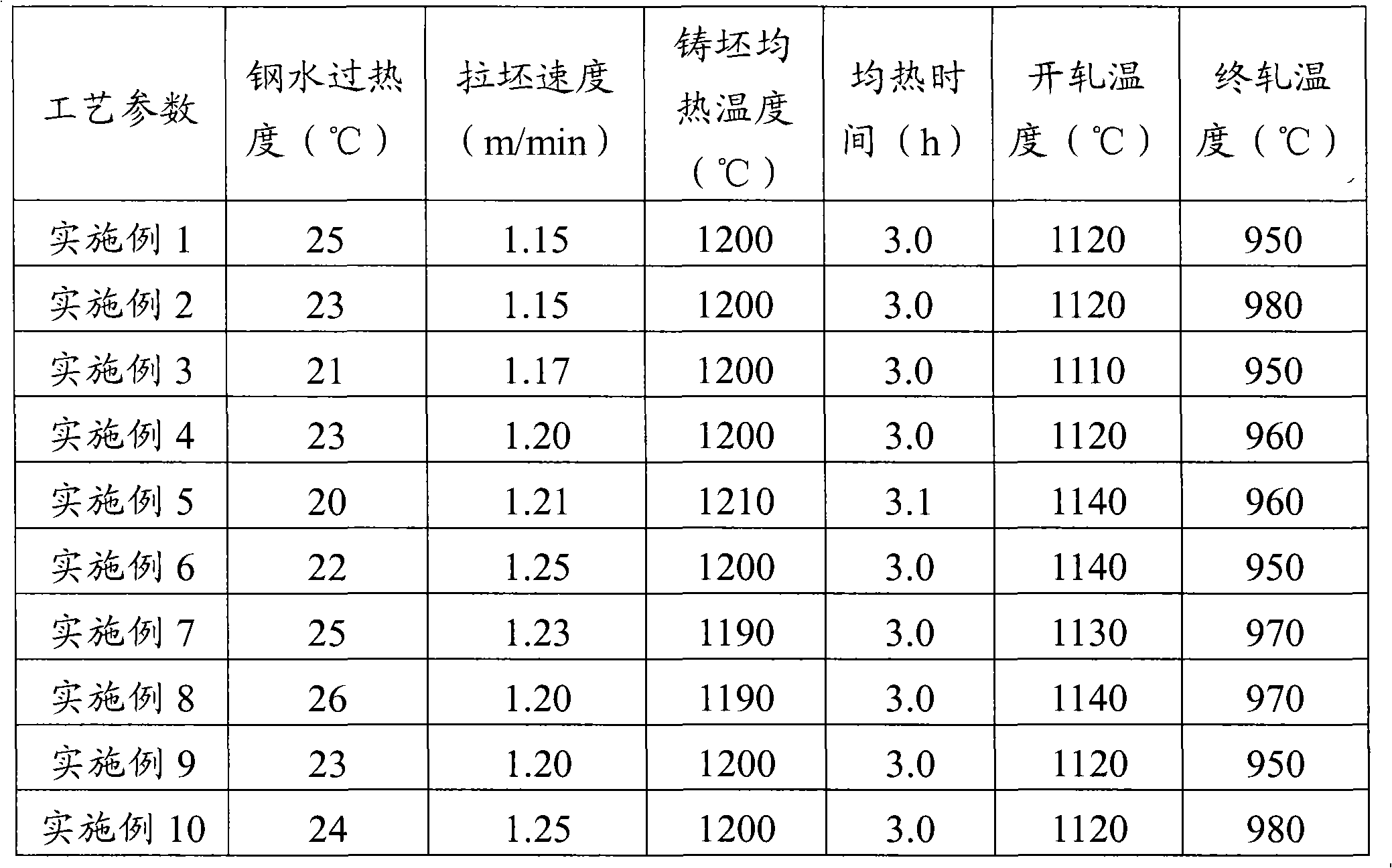

[0020] The preparation method of above-mentioned steel according to the present invention, comprises the following steps:

[0021] (1) Smelting molten steel; (2) Treating molten steel by refining process outside the furnace, controlling the composition of molten steel by weight percentage: C: 0.75-0.85%, Si: 0.17-0.35%, Mn: 0.70-0.90%, Cr : 0.40~0.60%, Al: 0.010~0.060%, Cu≤0.20%, Ni≤0.20%, P≤0.030%, S≤0.030%, total oxygen content O≤0.002%, the balance is Fe and unavoidable impurities (3) adopting the continuous casting process to form the cast slab from the molten steel refined outside the furnace; (4) preheating the cast slab, and then rolling it to obtain the steel ball for the ball mill.

[0022] Hereinafter, the ball mill steel ball according to the present invention will be mainly carried out in the technological process including ultra-high power electric furnace (UHP), ladle furnace refining method (LF), vacuum degassing method (VD), continuous casting and continuous ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com