Electroslag remelting production method of high-strength high-plasticity TWIP (Twinning Induced Plasticity) steel

A technology of electroslag remelting and production method, which is applied in the field of metallurgy to achieve the effect of reducing aluminum burning loss, preventing cracks and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

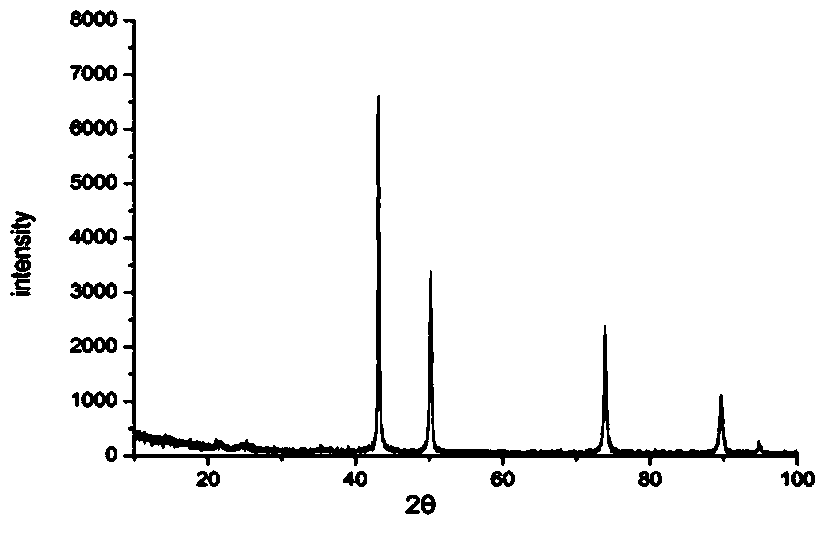

Image

Examples

Embodiment Construction

[0047] The target composition of smelted TWIP steel is shown in Table 1.

[0048] Table 1 TWIP steel chemical composition control requirements, %

[0049] element C Si mn P S Al chemical composition ≤0.04 2.55~3.05 24.00~26.00 ≤0.025 ≤0.005 2.90~3.50

[0050] 1) Preparation of electrode ingot

[0051] According to the target composition requirements, the chemical composition control of the electrode ingot before electroslag remelting is shown in Table 2.

[0052] Table 2 Chemical composition control of TWIP steel electrode ingot, %

[0053]

[0054] Determine the size of the electrode ingot according to the size of the target product. This example plans to produce about 14 tons of TWIP steel by electroslag remelting, so two 7.3t electrode ingots are prepared, and then continuously smelted by electroslag remelting to obtain TWIP steel electroslag ingots with a weight of about 14 tons. Among them, the size of the electrode ingot is φ580 / 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com