Light and high-performance twin crystal inducing plasticity steel and preparation method thereof

A twinning-induced plasticity and high-performance technology, applied in the field of metal materials, can solve the problems of prolonging product production cycle, reducing production efficiency, increasing energy consumption, etc., to avoid defects of hot-rolled billets, reduce component segregation, and reduce material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Table 1 shows the chemical composition of the high-strength twin-induced plasticity steel plate with good formability used in Example 1 of the present invention. Its preparation process is as follows:

[0023] The steel ingot with the above composition is hot-rolled and cold-rolled at a reduction rate of 43% to make a steel plate with a thickness of 2.4mm; the steel plate is heated to 600-900°C in a heat treatment furnace, and isothermally maintained for 600-1200s, followed by 10- After cooling to room temperature at 20°C / s, a TWIP steel plate with good strong ductility and high formability can be obtained.

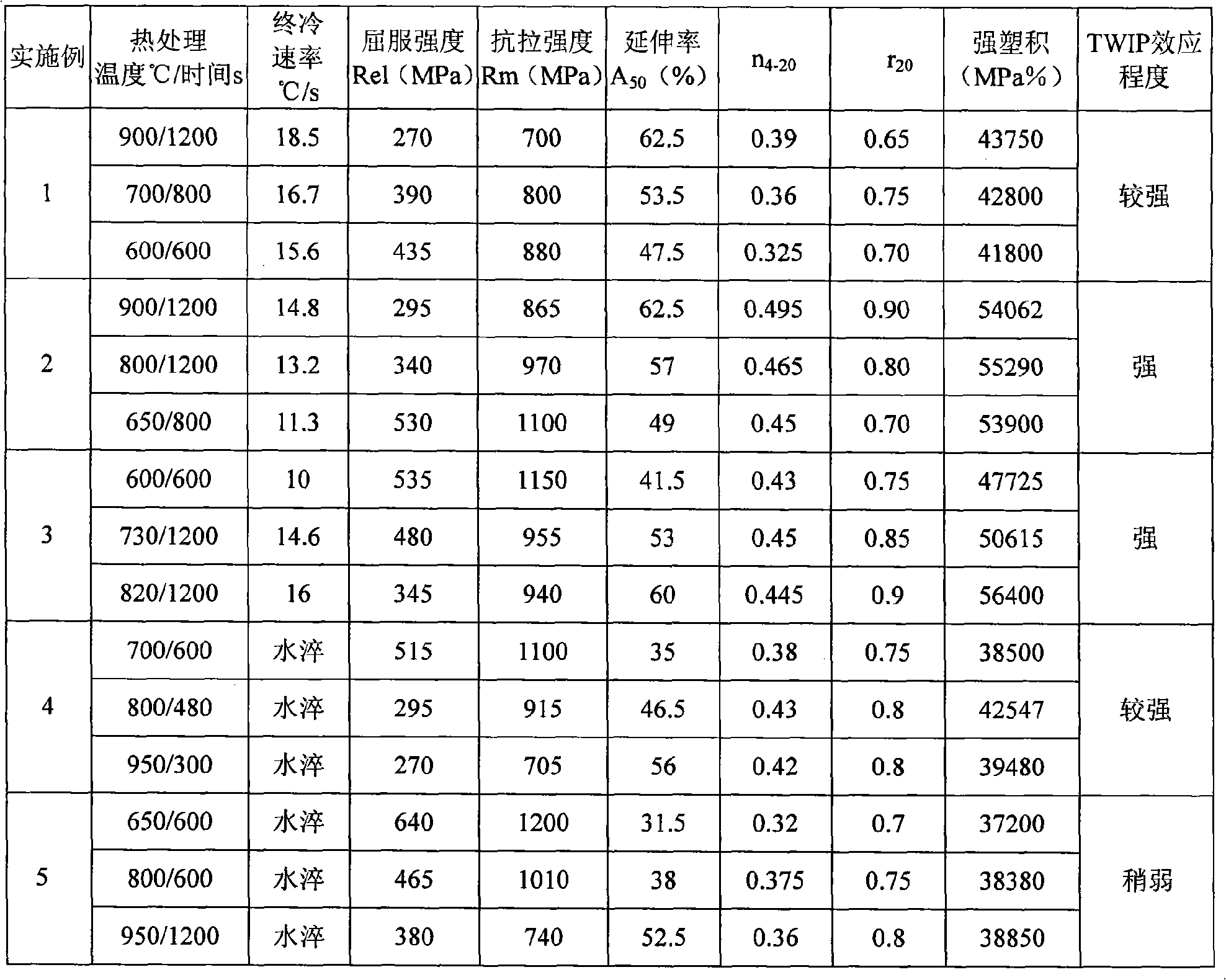

[0024] After testing, the relative amount of the microstructure of the steel plate after heat treatment is: 80%-90% austenite, 0-10% martensite, and the rest is ferrite. The mechanical properties of the steel plates after heat treatment are shown in Table 2. It can be seen from Table 2 that the high-strength TWIP steel plate with good formability obtained by the ...

Embodiment 2

[0026] Table 1 shows the chemical composition of the high-strength twin-induced plasticity steel plate with good formability used in Example 2 of the present invention. Its preparation process is as follows:

[0027] The steel ingot with the above composition is hot-rolled and cold-rolled at a reduction rate of 57% to form a steel plate with a thickness of 1.9mm; the steel plate is heated to 700-900°C in a heat treatment furnace, and isothermally held for 600-1200s, and then heated at 10-15°C / s is cooled to room temperature, that is, a TWIP steel plate with good strong plasticity and high formability is obtained.

[0028] After testing, the relative microstructure of the steel plate after heat treatment is: austenite 90%-100%, martensite+ferrite 0-10%. The mechanical properties of the steel plates after heat treatment are shown in Table 2. It can be seen from Table 2 that the method of the present invention can obtain a high-strength twin-induced plastic steel plate with a ...

Embodiment 3

[0030] Table 1 shows the chemical composition of the high-strength twin-induced plasticity steel plate with good formability used in Example 3 of the present invention. Its preparation process is as follows:

[0031] The steel ingot with the above composition is hot-rolled and cold-rolled at a reduction rate of 50% to form a steel plate with a thickness of 2.0 mm; s is cooled to room temperature, that is, a TWIP steel plate with good strong plasticity and high formability is obtained.

[0032]After testing, the relative microstructure of the steel plate after heat treatment is: 85%-95% austenite, 5%-15% martensite+ferrite. The mechanical properties of the steel plates after heat treatment are shown in Table 2. It can be seen from Table 2 that the high-strength TWIP steel plate with good formability obtained by the method of the present invention has a maximum tensile strength of 990 MPa, an elongation of 60%, and an n value of 0.46. The use of this composition and productio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com