Casting roll for twin roll strip caster

A technology of casting rolls and continuous casting machines, applied in casting equipment, casting melt containers, manufacturing tools, etc., can solve problems such as reduction in tensile strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

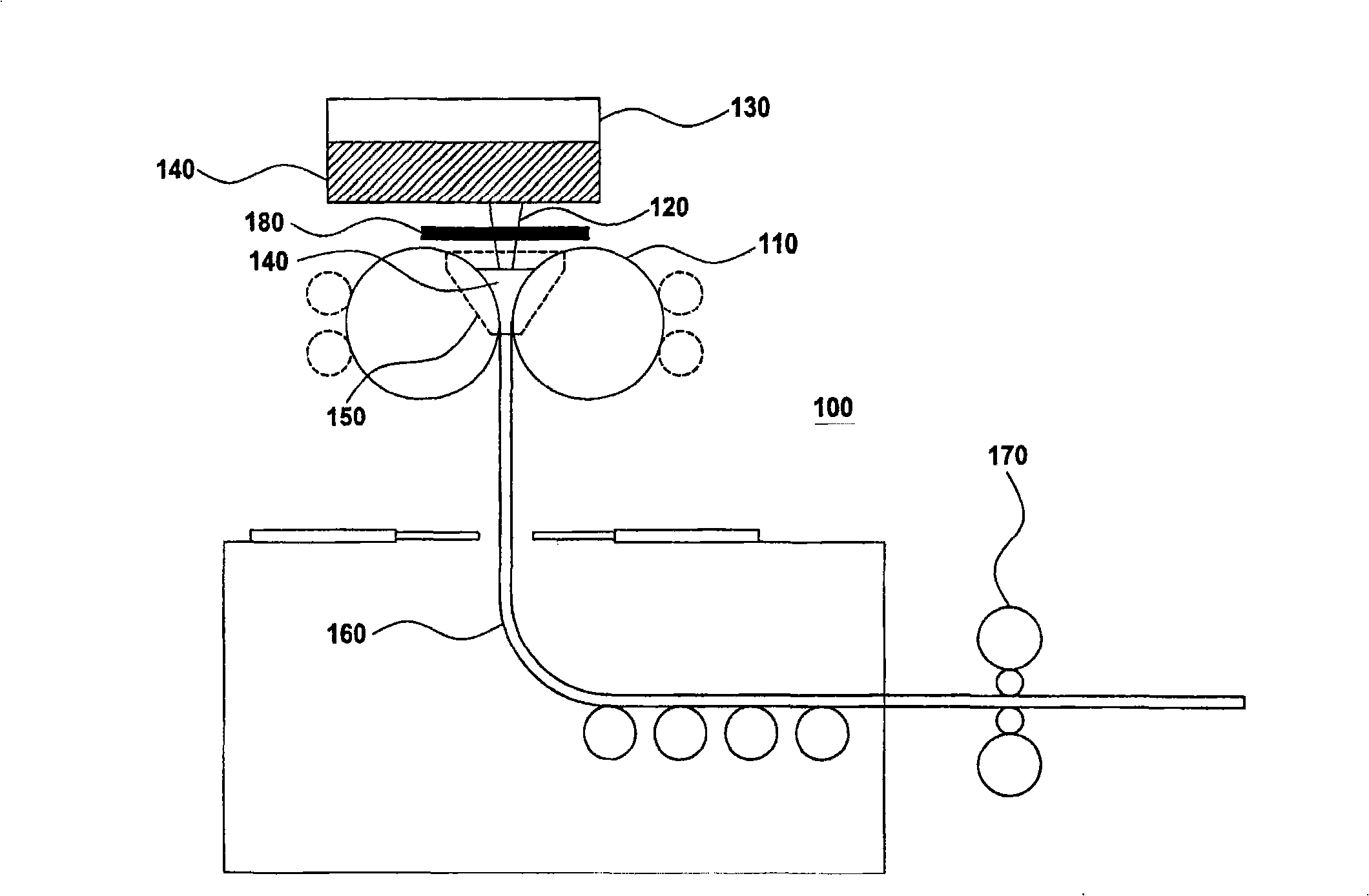

[0045] The present invention will be specifically described below in conjunction with the accompanying drawings.

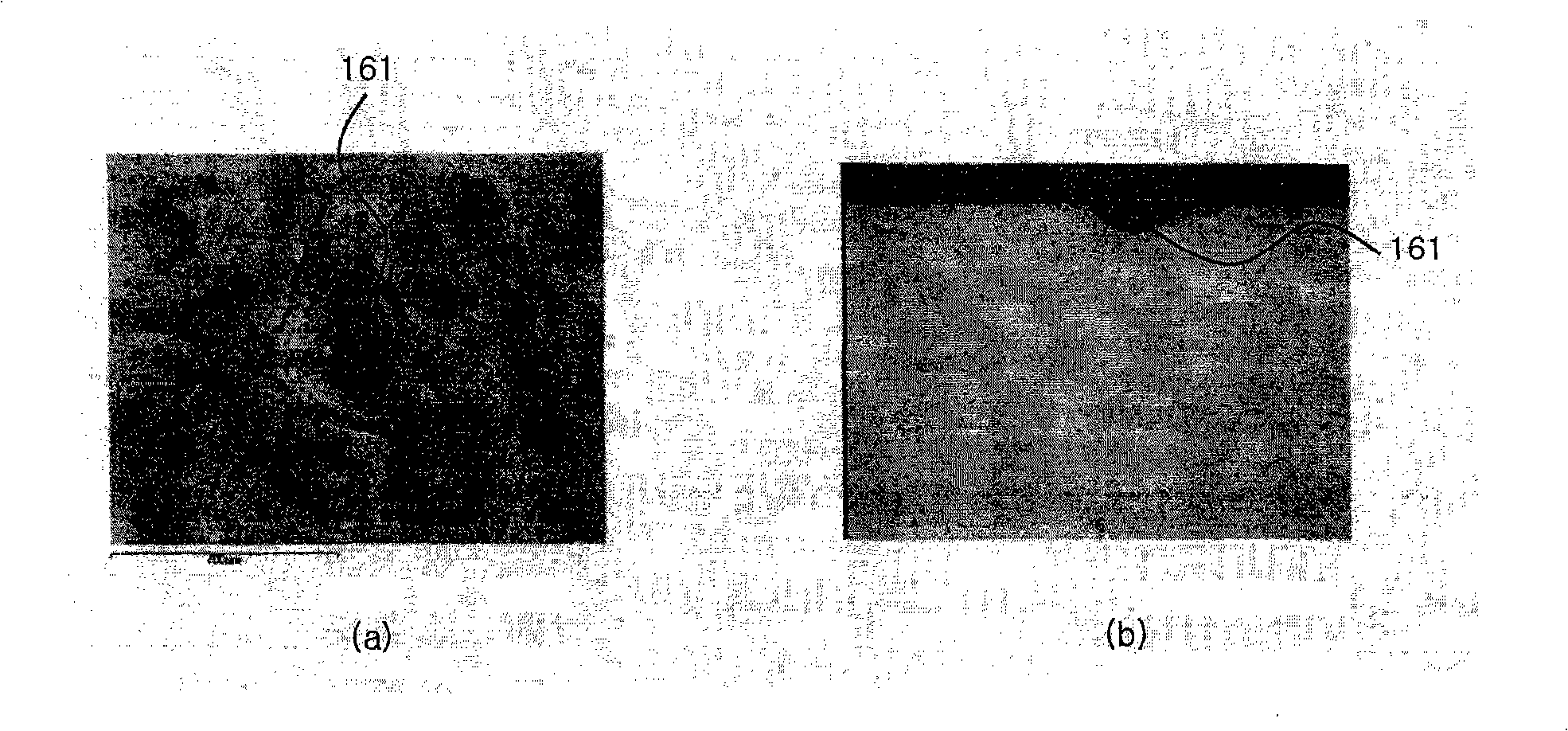

[0046] When casting TWIP steel into strip, casting rolls that have been surface treated by shot blasting (such as image 3 shown in ) and casting rolls using LBT-surface treated casting rolls (such as Figure 4 ) In both cases, indentations were produced in the surface layer of the strip. The dents are hemispherical depressions with a diameter of 0.5-3 mm and a depth of 0.1-1 mm generated in the surface layer of the strip, which have not been completely removed even by line hot rolling with a rolling reduction of 10-50%.

[0047] Depend on Figure 5 , it can be clearly seen that the indentation is produced by the depression in the surface layer of the casting roll.

[0048] Figure 5 (a) illustrates depressions formed in the surface layer of casting rolls by shot peening, and Figure 5 (b) illustrates dimples in the skin of a strip cast with a casting roll ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com