Electrolytic polishing method for high-strength hot rolling low carbon twinning induced plasticity (TWIP) steel

A twin-induced plasticity, electrolytic polishing technology, applied in the field of high-strength steel electrolytic polishing, can solve the problems affecting the authenticity of the original structure observation and the test test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The composition of the TWIP steel in this embodiment (in terms of mass percentage) is 28.06 for Mn (%), 2.55 for Si (%), 2.25 for Al (%), 0.0076 for C (%), and the rest is Fe.

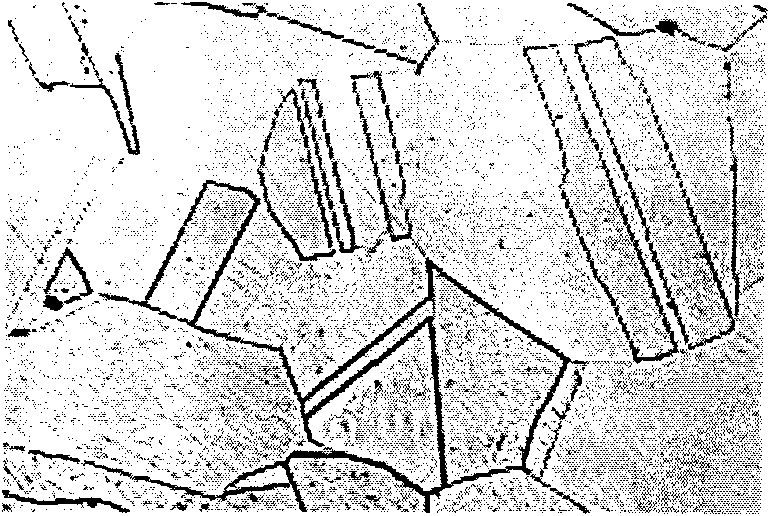

[0018] Measure ethanol, perchloric acid, and glycerin in proportion, pour them into the electrolytic cell in turn, put the electrolytic cell on an electronic induction stirrer, and stir evenly with electricity. Then fix the cathode of the electrolytic polishing and corrosion instrument at one end of the electrolytic cell, connect the TWIP steel sample to the anode of the electrolytic polishing and corrosion instrument, put it into the electrolytic cell, keep the distance between cathode and anode at 5 cm, and set the working voltage of the electrolytic polishing and corrosion instrument 20V, working current density 1A / cm 2 , Polishing time 80 seconds. Turn on the electronic induction stirrer switch to keep the electrolyte in a stirred state; turn on the working switch of the electrolytic polish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com