Manganese-containing steel and production method therefor

A production method and technology of manganese steel, applied in the field of iron and steel metallurgy, can solve the problems of high comprehensive work hardening rate, low elongation, insufficient yield strength and tensile strength, etc., and achieve high market application value and low manganese content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

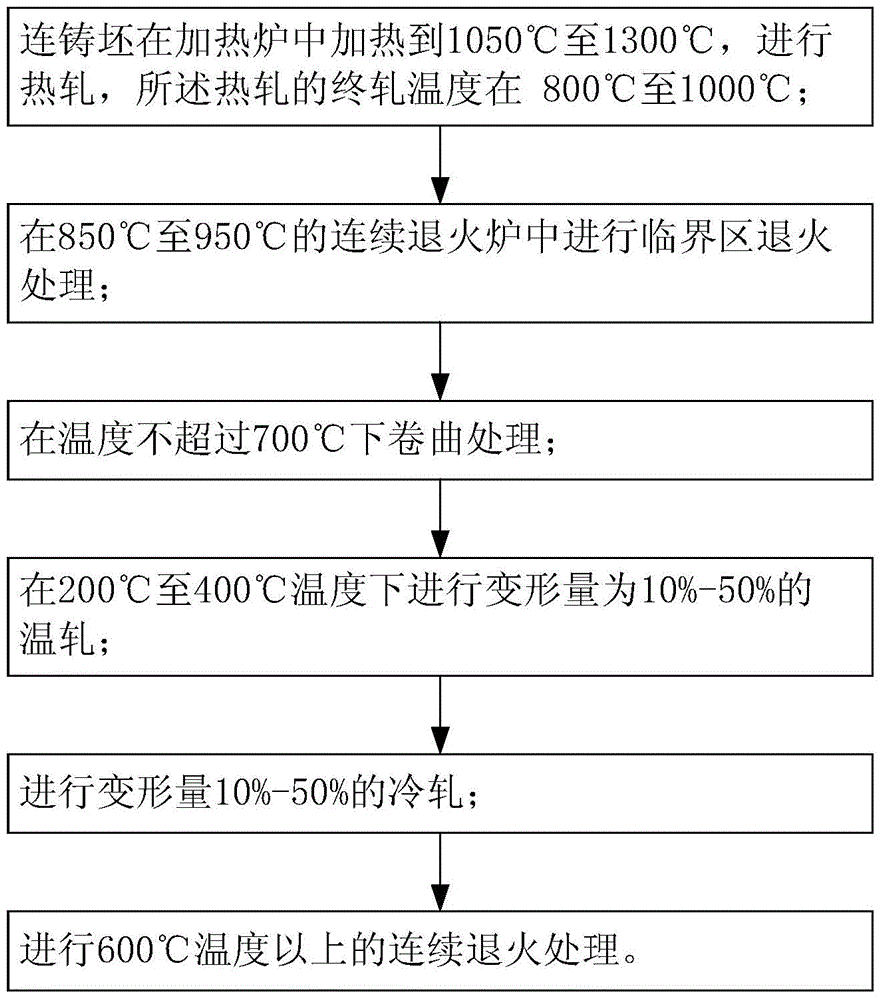

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0019] A manganese-containing steel, which comprises the following components by mass percentage: carbon 0.2-1.0%, manganese 5-15%, aluminum 0.02-1.0%, phosphorus <0.025%, sulfur <0.025%, nitrogen <0.03%, silicon 0.03-2%; and, it also includes at least one of the following alloying elements: titanium 0.01-1.2%, niobium 0.01-1.2%, vanadium 0.01-1.2%; the balance is iron. For example, carbon (C): 0.2-1.0%, when the carbon content is less than 0.2%, it is easy to produce martensite, cracks are likely to occur during continuous casting and rolling, and the plasticity of the steel is reduced. When the carbon content is high At 1.0%, the stacking fault energy increases rapidly, and the deformation mechanism of the material changes from martensite transformation and deformation twinning to dislocation slip; in other words, when the carbon content is higher than 1.0%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com