High-strength twip steel sheet and method of manufacturing the same

a steel sheet, high-strength technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of difficult economic production of products, low initial collision performance, complicated parts formed into, etc., and achieve the effect of improving the elongation ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

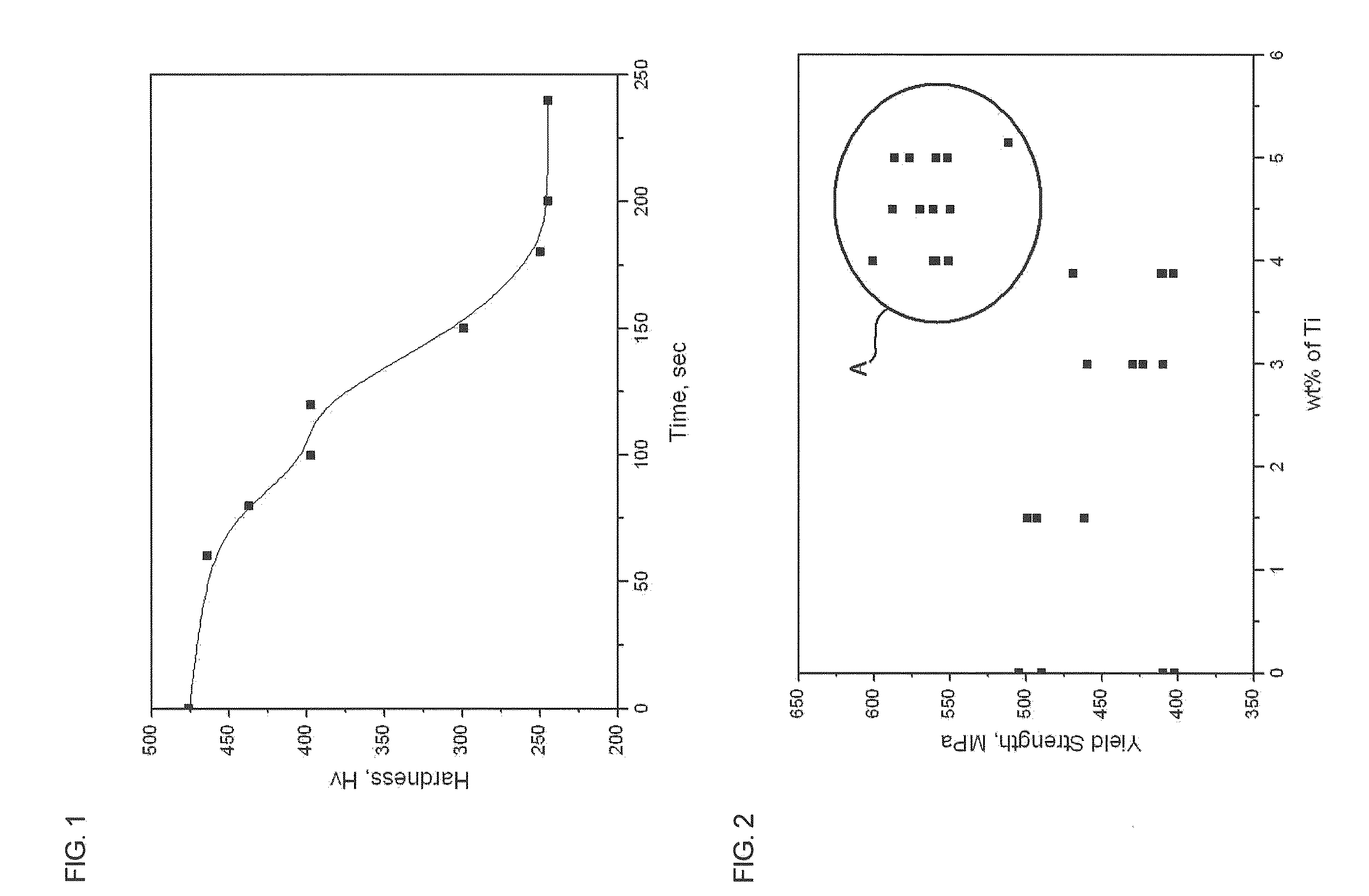

[0037]Accordingly, the present invention features, in preferred embodiments, two methods of suitably applying titanium to a TWIP steel sheet. In a first embodiment, interstitial free (IF) steel to which titanium (Ti) is preferably added through a low-cost process is suitably melted in a vacuum furnace, and then carbon and other components are added to the melted IF steel. Preferably, in this method, the oxidization of the titanium (Ti) added to the IF steel can be suitably prevented, and titanium (Ti) is not required to be further added thereto, so that this method may be a suitably economical method.

second embodiment

[0038]In a second embodiment, a powdered titanium-manganese (Ti—Mn) alloy is preferably prepared and then suitably added to steel at the time of refining the steel. Preferably, when the steel is made in the form of a metal matrix composite (MMC), the steel can have a desired component ratio without being influenced by its composition. In further preferred embodiments, when this MMC steel is suitably charged into the vacuum furnace, it is easily melted because the titanium-manganese (Ti—Mn) alloy powder has high surface energy (large surface area). Accordingly, in further related embodiments, it is suitably easily supercooled. This method is advantageous in terms of component control.

[0039]In certain preferred embodiments of the present invention, the two methods were suitably employed, and final components and their material properties did not suitably differ from each other.

[0040]In other preferred embodiments of the invention, in order to suitably manufacture a high-strength TWIP ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com