High-toughness twinning induced plasticity (TWIP) nodular cast iron alloy and preparation method thereof

A technology of ductile iron and alloy, which is applied in the field of high strength and toughness TWIP ductile iron alloy and its preparation, can solve the problems restricting the application of cast iron, and achieve the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A high-strength, high-toughness austenite-based TWIP cast iron alloy is prepared by using a high-frequency induction heating melting furnace to carry out smelting, spheroidizing, and inoculating processes in an air environment, and pouring it into a graphite mold; The preparation steps are as follows:

[0027] 1) Loading: Add pig iron, ferrosilicon, graphite, manganese flakes, and nickel raw materials in sequence in the melting crucible, and heat and melt in the atmospheric environment with an ordinary medium-frequency induction melting furnace;

[0028] 2) Smelting: The smelting temperature is controlled at 1600~1700°C, and the holding time is 8-15 minutes. After the liquid metal is melted evenly, add 1.5~2.5% of 5-8 brand rare earth magnesium spheroidizer for spheroidization treatment, and then filter the residue;

[0029] 3) Casting: Pour the smelted liquid into the pre-dried graphite mold through the graphite pouring cap;

[0030] 4) Cooling: After the sample is co...

Embodiment 1

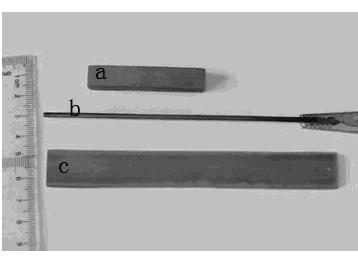

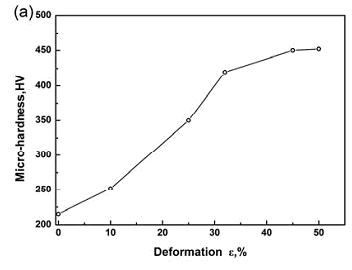

[0036] Using industrial pig iron (1.0% Si, 4.0% C, the rest is Fe, wt%) as the basic raw material, electrolytic nickel with a purity of 99.8%, graphite powder with a purity of 99.8%, electrolytic manganese with a purity of 99.8% and Si 75% ferrosilicon is used as an alloying element added in the inoculation treatment, and the chemical composition is formulated according to the mass fraction (wt%): C3.5%, Mn12%, Ni15%, Si2.5%, rare earth Mg2.0%, S 0.03%, P 0.05%, and the balance is Fe cast iron alloy, which is smelted in an air environment by using a high-frequency induction heating melting furnace. Then the alloy ingot is kept at a high temperature of 950°C for 6 hours for a long time, so that all the carbides in the as-cast structure are dissolved into the matrix austenite, and then rapidly quenched and cooled to obtain a uniform single-phase austenite structure. Strips of a certain thickness are cut from the sample after solution treatment, and rolled into deformed strips of...

Embodiment 2

[0039] On the basis of Example 1, the sample after cold rolling was subjected to high temperature recovery recrystallization, the recrystallization temperature was controlled at 900° C., and the holding time was 60 minutes.

[0040] The mechanical properties of the recrystallized state of the above-mentioned cast iron material are measured as: the material of the present invention is recrystallized through high temperature recovery after cold deformation, and shows better strength and higher elongation under tensile conditions (see Table 1, Figure 5 ), the tensile strength can be increased to 730.81MPa, and the corresponding elongation δ is as high as more than 20%. It is more than 6.7 times that of -3, showing high plasticity, meeting the plasticity requirements of industrial structural materials, and possessing the ability of plastic processing and forming. Image 6 It is the appearance after fracture of the Fe-15Ni-12Mn-3.5C-2.5Si alloy cast iron plate tensile specimen aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com